Growing Awareness of Environmental Impact

There is a rising awareness regarding the environmental impact of materials used in various industries, which appears to be influencing the Polycrystalline Fiber Market. As consumers and businesses alike become more conscious of sustainability, the demand for eco-friendly materials is likely to increase. Polycrystalline fibers, which can be produced with lower environmental footprints compared to traditional materials, may see heightened interest. This shift in consumer preferences could lead to a significant transformation in the market landscape, as manufacturers adapt their offerings to align with sustainable practices and meet regulatory requirements.

Advancements in Manufacturing Technologies

Technological innovations in the production of polycrystalline fibers are likely to enhance the efficiency and quality of these materials. Recent advancements, such as improved synthesis methods and automated production processes, have the potential to lower production costs and increase output. This could lead to a more competitive landscape within the Polycrystalline Fiber Market. Furthermore, the integration of smart manufacturing technologies may facilitate real-time monitoring and quality control, ensuring that the fibers meet stringent industry standards. As a result, manufacturers may find themselves better positioned to meet the evolving demands of various sectors, including electronics and textiles.

Rising Demand for Energy-Efficient Materials

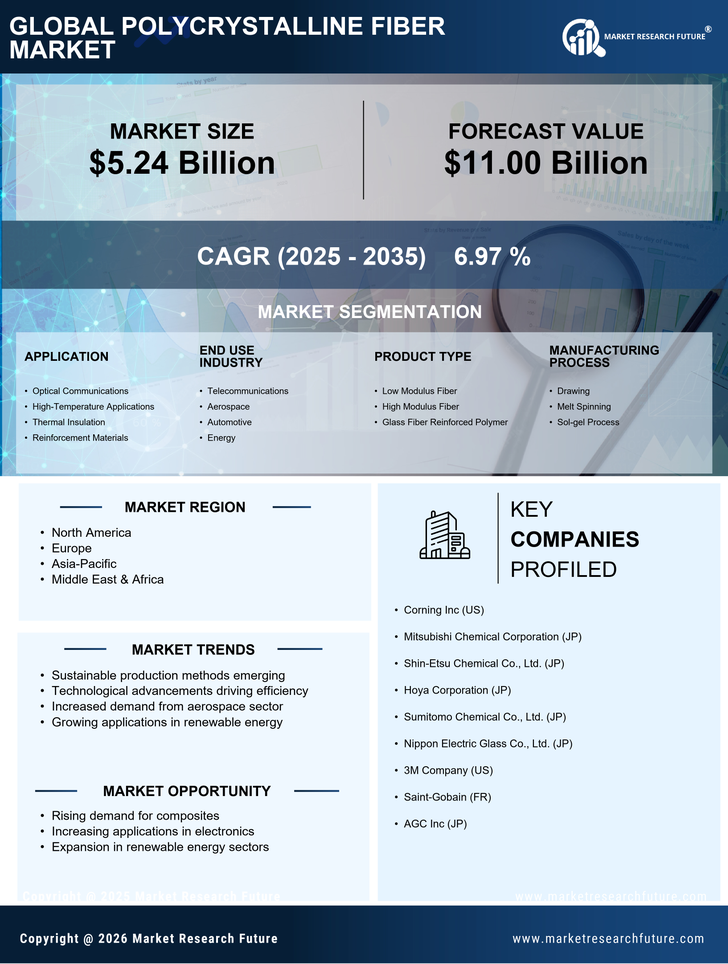

The increasing emphasis on energy efficiency across various industries appears to drive the Polycrystalline Fiber Market. As organizations seek to reduce their carbon footprints, the demand for materials that enhance energy efficiency is likely to rise. Polycrystalline fibers, known for their thermal stability and insulation properties, are becoming a preferred choice in applications such as construction and automotive. According to recent data, the market for energy-efficient materials is projected to grow at a compound annual growth rate of approximately 8% over the next five years. This trend suggests that the Polycrystalline Fiber Market could experience substantial growth as manufacturers align their products with sustainability goals.

Expanding Applications in the Electronics Sector

The electronics industry is increasingly adopting polycrystalline fibers due to their unique properties, which include high thermal conductivity and electrical insulation. This trend is expected to bolster the Polycrystalline Fiber Market significantly. With the rise of advanced electronic devices and the Internet of Things, the demand for materials that can withstand high temperatures and provide reliable insulation is on the rise. Market data indicates that the electronics segment is anticipated to account for a substantial share of the overall polycrystalline fiber market, potentially reaching a valuation of several billion dollars by 2030. This growth reflects the material's versatility and suitability for various applications.

Increased Investment in Research and Development

Investment in research and development within the Polycrystalline Fiber Market is likely to yield innovative products and applications. Companies are focusing on enhancing the properties of polycrystalline fibers, such as their strength, durability, and resistance to environmental factors. This investment is expected to lead to the development of next-generation fibers that can cater to specialized applications in aerospace, automotive, and medical sectors. As R&D efforts intensify, the market may witness the introduction of advanced materials that offer superior performance, thereby attracting new customers and expanding market reach.