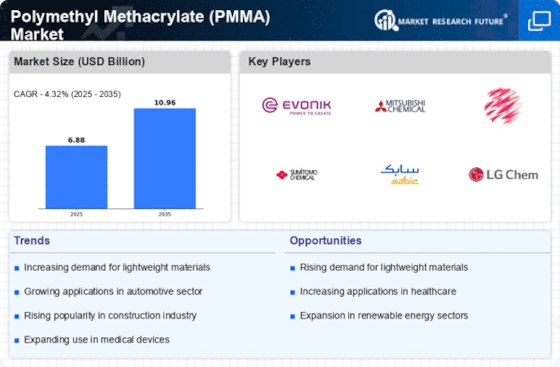

Top Industry Leaders in the Polymethyl Methacrylate PMMA Market

Polymethyl Methacrylate (PMMA), commonly known as acrylic, reigns supreme in the realm of transparent thermoplastics. Its versatility, durability, and optical clarity make it a coveted material across various industries, from construction and automotive to medical and electronics. But within this seemingly clear market, a dynamic competition unfolds, with key players vying for dominance. Let's dive into the multifaceted world of PMMA, exploring the strategies, market share drivers, and recent developments shaping its landscape.

Strategies Adopted by PMMA Titans:

-

Product Diversification: Leading companies are expanding their product portfolios beyond basic PMMA sheets and pellets. Lucite International, for instance, offers specialty grades for optical lenses and medical applications, while Mitsubishi Chemical Corporation focuses on high-performance PMMA for automotive and aerospace use. -

Geographic Expansion: Emerging economies in Asia Pacific, particularly China and India, present lucrative opportunities. Companies like Evonik Industries and Röhm GmbH are actively investing in production facilities in these regions to cater to the rising demand. -

Technological Advancements: Innovation plays a crucial role in differentiating players. Sumitomo Chemical is developing PMMA with improved fire retardancy and scratch resistance, while Covestro is focusing on bio-based PMMA alternatives. -

Vertical Integration: Some players are integrating upstream and downstream to secure raw materials and control costs. Mitsubishi Chemical, for example, owns acrylic monomer production facilities, while LG Chem operates retail channels for finished acrylic products. -

Sustainability Initiatives: Environmental concerns are gaining traction. Companies are adopting sustainable practices, such as using recycled materials and optimizing energy consumption, to attract environmentally conscious customers.

Factors Dictating Market Share:

-

Production Capacity and Efficiency: Companies with larger production capacities and efficient manufacturing processes can offer competitive pricing and secure larger contracts. -

Quality and Product Portfolio: High-quality products and a diverse range of PMMA grades cater to specific industry needs and attract a broader customer base. -

Brand Recognition and Reputation: Established brands like Plexiglas and Altuglas command premium prices and enjoy customer loyalty due to their reputation for reliability and innovation. -

Geographical Presence: Strong presence in key markets, particularly China and Southeast Asia, grants access to a larger consumer base and facilitates efficient distribution. -

Research and Development: Continuous innovation in product offerings and production processes keeps companies ahead of the curve and unlocks new market opportunities.

Key Companies in the Polymethyl Methacrylate (PMMA) Market includes

- Trinseo (US)

- ROHM GMBH (Germany)

- Kuraray Co. Ltd. (Japan)

- GEHR Plastics, Inc (Germany)

- Mitsubishi Chemical Corporation (Japan)

- Plazit Polygal (US)

- Sumitomo Chemical Company (Japan)

- 3A Composites GmbH (Switzerland)

- RTP Company (US)

- Asahi Kasei Corporation (Japan)

Recent News

December 2022: Rohm GmbH, a prominent manufacturer of methacrylates, has agreed to buy SABIC's Functional Forms division, subject to usual engagement with the respective works councils and antitrust approval. SABIC's functional forms division will design and produce polycarbonate resin polymethylmethacrylate (PMMA) sheets and films for a variety of industrial sectors, including building and construction, consumer electronics, medicine, and aerospace. The transaction is expected to close in the first half of 2024.

December 2022: Sumitomo Chemical has built a new pilot facility for the chemical recycling of Polymethyl Methacrylate (PMMA) at its Ehime Works in Niihama City, Ehime Prefecture, Japan. Samples of chemically recycled methyl methacrylate or MMA monomer generated in this facility, as well as Polymethyl Methacrylate (PMMA) produced from the monomer, will be available from spring 2023.

October 2022: Trinseo and Japan Steel Works Europe GmbH (JSW EU) announced a partnership on the chemical recycling of polymethyl methacrylate (PMMA).

July 2022: Trinseo launched its new series ALTUGLAS R-Life Acrylics, for the European marketplace. ALTUGLAS R-Life is a brand umbrella for chemically and mechanically recycled, reused, and bio-based polymethyl methacrylate (PMMA) sheets, resins, and compounds.

Specialty material solutions provider Trinseo is targeting to advance sustainable plastics in December 2023 with its polymethyl methacrylate (PMMA) depolymerisation plant in Rho, Italy, which appears to make recycling of PMMA-based materials efficient.

July 2022: Rohm GmbH disclosed plans to expand the production capacity of PLEXIGLAS, a special molding compound for PMMA in Shanghai, to strengthen its market position in China.

July 2022: Rohm GmbH revealed that it would increase its output capacity for PLEXIGLAS – an amorphous thermoplastic molding compound based on PMMA – at Worms, Germany, since the demand for branded PMMA in global markets is high.

August 2021: On August 22nd, Rohm GmbH disclosed plans to establish new technology centers in Shanghai, China and Connecticut, USA, with the aim of becoming a leading technology supplier of methacrylates by offering modern technical applications and development labs for innovative applications.

In 2021, Plazit-Polygal was acquired by Plaskolite LLC, a leading supplier of thermoplastic sheet materials. Among other things, the company expects to acquire the operations of Plazit-Polygal in South America, North America and Europe.