Expansion of End-Use Industries

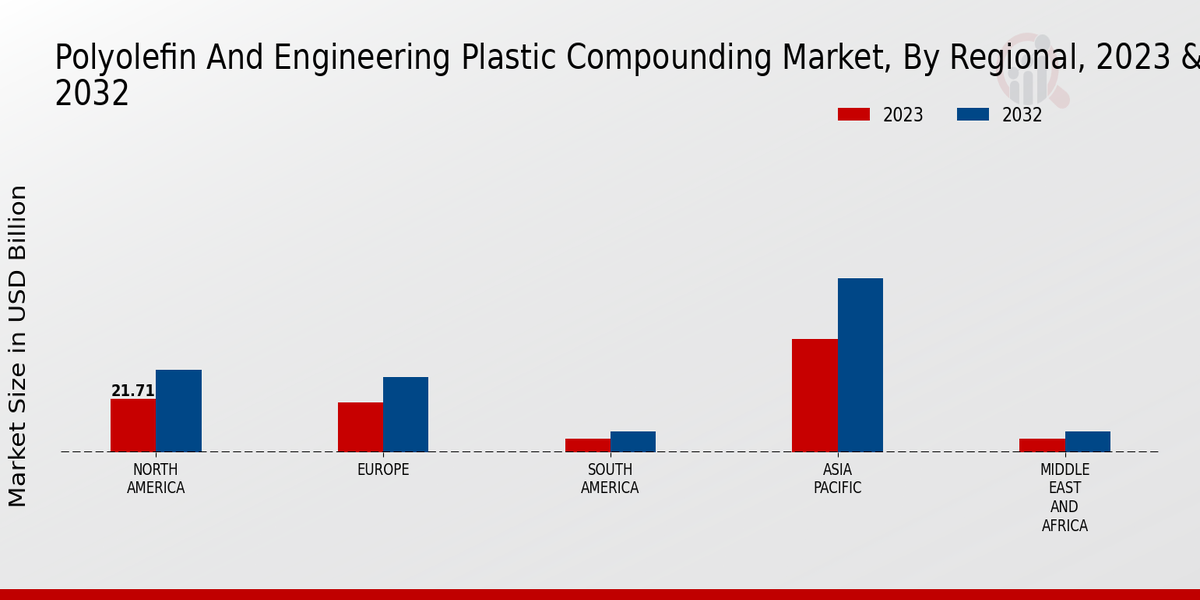

The expansion of end-use industries such as automotive, construction, and consumer goods is a significant driver for the Global Polyolefin and Engineering Plastic Compounding Market Industry. As these industries grow, the demand for high-performance materials that can withstand various environmental conditions increases. Polyolefins and engineering plastics are favored for their versatility, chemical resistance, and mechanical properties. This trend is expected to fuel market growth, with the industry projected to reach substantial values in the coming years. The diversification of applications across multiple sectors indicates a robust demand for compounded materials.

Increasing Focus on Sustainability

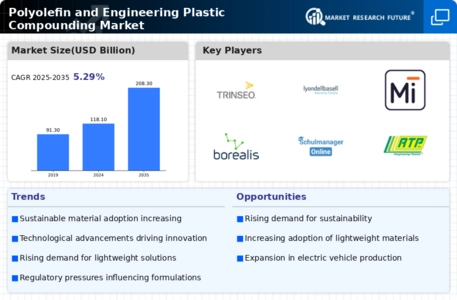

Sustainability is becoming a crucial factor in the Global Polyolefin and Engineering Plastic Compounding Market Industry. As environmental concerns rise, manufacturers are increasingly focusing on developing eco-friendly materials and processes. The demand for recyclable and biodegradable polyolefins is growing, driven by consumer preferences and regulatory pressures. Companies are investing in research and development to create sustainable alternatives that do not compromise on performance. This shift towards sustainability is likely to reshape the market landscape, encouraging innovation and potentially leading to a compound annual growth rate of 5.29% from 2025 to 2035.

Market Trends and Growth Projections

Rising Demand for Lightweight Materials

The Global Polyolefin and Engineering Plastic Compounding Market Industry experiences an increasing demand for lightweight materials across various sectors, particularly in automotive and aerospace. Manufacturers are seeking to reduce vehicle weight to enhance fuel efficiency and reduce emissions. For instance, polyolefins are favored for their excellent strength-to-weight ratio, which contributes to overall vehicle performance. This trend is expected to drive the market's growth, with the industry projected to reach 118.1 USD Billion in 2024. As companies innovate in material science, the adoption of advanced polyolefin compounds is likely to accelerate, further propelling market expansion.

Growing Applications in the Packaging Sector

The packaging sector is a major driver for the Global Polyolefin and Engineering Plastic Compounding Market Industry, as polyolefins are widely used in flexible and rigid packaging solutions. Their excellent barrier properties, durability, and lightweight nature make them ideal for food and consumer goods packaging. The shift towards sustainable packaging solutions further enhances the demand for engineered plastics that can be recycled or reused. As the global population continues to grow, the need for efficient packaging solutions is expected to rise, thereby bolstering market growth. This sector's expansion is anticipated to contribute significantly to the overall market value.

Technological Advancements in Compounding Processes

Technological advancements in compounding processes significantly influence the Global Polyolefin and Engineering Plastic Compounding Market Industry. Innovations such as twin-screw extrusion and advanced blending techniques enhance the efficiency and quality of compounded materials. These processes allow for better control over material properties, leading to improved performance in end applications. As manufacturers adopt these technologies, they can produce more complex formulations that meet specific industry requirements. The ongoing evolution in compounding technology is likely to support the market's growth trajectory, contributing to the projected increase to 208.3 USD Billion by 2035.