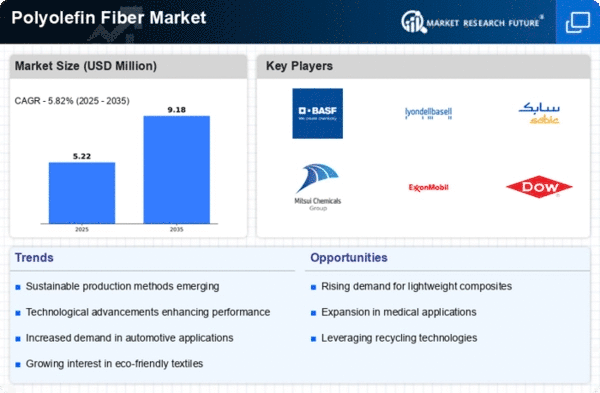

Market Growth Projections

The Global Polyolefin Fiber Market Industry is projected to experience robust growth in the coming years. With a market size expected to reach 12.5 USD Billion in 2024 and 25 USD Billion by 2035, the industry is poised for significant expansion. The anticipated compound annual growth rate of 6.5% from 2025 to 2035 indicates a strong upward trajectory, driven by increasing demand across various sectors. This growth is likely to be fueled by advancements in technology, rising applications in diverse industries, and a growing emphasis on sustainability.

Growing Demand for Lightweight Materials

The Global Polyolefin Fiber Market Industry is experiencing a surge in demand for lightweight materials across various sectors, including automotive, textiles, and construction. This trend is driven by the need for energy-efficient solutions and improved fuel economy in vehicles. For instance, polyolefin fibers are increasingly utilized in automotive interiors and lightweight composites, contributing to overall vehicle weight reduction. As a result, the market is projected to reach 12.5 USD Billion in 2024, reflecting a growing preference for materials that enhance performance while minimizing weight.

Rising Applications in Non-Woven Fabrics

The Global Polyolefin Fiber Market Industry is witnessing a notable increase in the use of polyolefin fibers in non-woven fabrics. These fabrics are utilized in various applications, including hygiene products, medical supplies, and industrial textiles. The versatility of polyolefin fibers, combined with their cost-effectiveness, makes them an attractive choice for manufacturers. As the demand for non-woven fabrics continues to rise, driven by factors such as population growth and increased healthcare needs, the market is poised for significant expansion. This trend contributes to the overall growth trajectory of the industry.

Sustainability and Eco-Friendly Practices

Sustainability is becoming a pivotal driver in the Global Polyolefin Fiber Market Industry, as manufacturers and consumers alike prioritize eco-friendly materials. Polyolefin fibers, being recyclable and less harmful to the environment, align with the increasing emphasis on sustainable practices. Industries are adopting these fibers to meet regulatory standards and consumer expectations for greener products. This shift towards sustainability is expected to bolster market growth, with projections indicating a market size of 25 USD Billion by 2035, as companies innovate to create more environmentally responsible offerings.

Technological Advancements in Fiber Production

Technological advancements play a crucial role in shaping the Global Polyolefin Fiber Market Industry. Innovations in production techniques, such as advanced spinning and weaving technologies, enhance the quality and performance of polyolefin fibers. These advancements allow for the creation of fibers with superior properties, such as increased durability and resistance to environmental factors. As manufacturers adopt these technologies, they can cater to diverse applications, further driving market growth. The anticipated compound annual growth rate of 6.5% from 2025 to 2035 underscores the potential for continued innovation in this sector.

Increasing Investment in Infrastructure Development

Investment in infrastructure development is a key driver for the Global Polyolefin Fiber Market Industry. Governments and private entities are allocating substantial resources to enhance infrastructure, including roads, bridges, and buildings. Polyolefin fibers are increasingly used in construction materials due to their strength, durability, and resistance to moisture. This trend is expected to propel market growth, as the demand for high-performance materials in construction continues to rise. The ongoing infrastructure projects worldwide are likely to create new opportunities for polyolefin fiber manufacturers, further solidifying their position in the market.