Technological Innovations

Technological advancements play a crucial role in shaping the Polyvinylidene Fluoride PVDF Coating Market. Innovations in coating formulations and application techniques have enhanced the performance characteristics of PVDF coatings, making them more appealing to manufacturers and end-users. For instance, the development of advanced spray technologies allows for more efficient application, reducing waste and improving coverage. Additionally, the integration of nanotechnology into PVDF coatings is expected to enhance their properties, such as scratch resistance and UV stability. As a result, the market is witnessing a shift towards high-performance coatings that meet the evolving demands of various industries, including aerospace and electronics, where precision and durability are essential.

Automotive Industry Growth

The automotive sector is experiencing a transformation that significantly impacts the Polyvinylidene Fluoride PVDF Coating Market. As manufacturers seek to improve vehicle performance and aesthetics, the demand for high-quality coatings is on the rise. PVDF coatings are particularly valued for their resistance to corrosion and UV degradation, making them ideal for exterior applications in vehicles. The automotive industry is projected to witness steady growth, driven by advancements in electric vehicles and lightweight materials. This shift is likely to increase the adoption of PVDF coatings, as they provide the necessary protection and visual appeal for modern automotive designs. Consequently, the market for PVDF coatings is expected to expand in tandem with the automotive sector's evolution.

Energy Sector Developments

Developments in the energy sector are emerging as a key driver for the Polyvinylidene Fluoride PVDF Coating Market. The growing focus on renewable energy sources, such as solar and wind, necessitates the use of durable and efficient materials. PVDF coatings are increasingly utilized in the manufacturing of solar panels and wind turbine components due to their excellent chemical resistance and longevity. As the energy sector continues to evolve, the demand for PVDF coatings is likely to rise, driven by the need for materials that can withstand harsh environmental conditions. This trend is expected to contribute to the overall growth of the PVDF coating market, as industries seek reliable solutions for energy applications.

Sustainability Initiatives

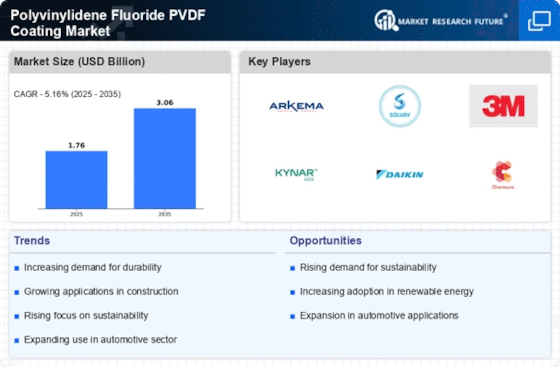

The increasing emphasis on sustainability is a pivotal driver for the Polyvinylidene Fluoride PVDF Coating Market. As industries strive to reduce their environmental footprint, PVDF coatings, known for their durability and resistance to harsh conditions, are gaining traction. These coatings are often utilized in applications that require long-lasting performance, thereby reducing the need for frequent replacements. The market for PVDF coatings is projected to grow at a compound annual growth rate of approximately 6% over the next few years, driven by the demand for eco-friendly materials. Furthermore, regulatory frameworks promoting sustainable practices are likely to bolster the adoption of PVDF coatings across various sectors, including construction and automotive, where longevity and environmental compliance are paramount.

Rising Construction Activities

The resurgence of construction activities is a significant driver for the Polyvinylidene Fluoride PVDF Coating Market. With urbanization and infrastructure development on the rise, the demand for durable and aesthetically pleasing building materials is increasing. PVDF coatings are particularly favored in architectural applications due to their excellent weather resistance and color retention properties. The construction sector is projected to expand, with investments in residential and commercial projects driving the need for high-quality coatings. This trend is further supported by government initiatives aimed at enhancing infrastructure, which is likely to propel the demand for PVDF coatings in the coming years. The market is expected to benefit from this growth, as PVDF coatings are increasingly specified in architectural designs.