Growth of the Construction Sector

The Portable Welding Generators Market is closely tied to the growth of the construction sector, which has been experiencing a resurgence in various regions. As infrastructure projects and residential developments gain momentum, the need for efficient welding solutions becomes critical. Portable welding generators are favored for their ability to provide on-site power, facilitating timely project completion. Recent statistics indicate that the construction industry is projected to grow at a rate of 4% annually, which bodes well for the portable welding generators market. This growth is likely to drive innovation and competition among manufacturers, leading to enhanced product offerings that cater to the evolving needs of construction professionals.

Increased Focus on Safety Standards

The Portable Welding Generators Market is also influenced by an increased focus on safety standards across various industries. As regulations become more stringent, companies are compelled to adopt equipment that meets safety requirements. Portable welding generators are designed with safety features that protect users from potential hazards associated with welding operations. This heightened emphasis on safety is driving demand for compliant and reliable equipment. Furthermore, as industries prioritize worker safety and operational efficiency, the adoption of portable welding generators is likely to increase. This trend not only supports the growth of the market but also encourages manufacturers to enhance safety features in their product offerings.

Rising Adoption in Remote Locations

The Portable Welding Generators Market is significantly influenced by the rising adoption of welding solutions in remote locations. As industries expand into less accessible areas, the need for portable welding generators becomes paramount. These generators provide essential power for welding operations where traditional power sources are unavailable. Data suggests that sectors such as oil and gas, mining, and infrastructure development are increasingly relying on portable welding generators to meet their operational needs. This trend not only enhances productivity but also ensures that projects can proceed without delays caused by power shortages. Consequently, the demand for portable welding generators is expected to rise as more companies recognize their value in remote applications.

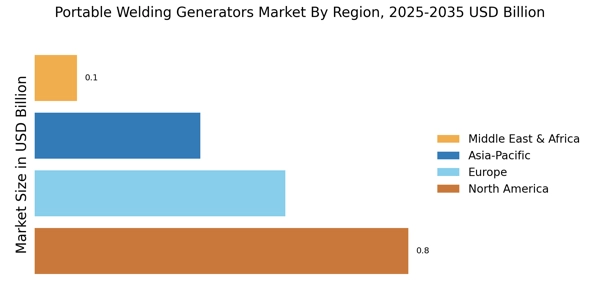

Increased Demand for Portable Power Solutions

The Portable Welding Generators Market is experiencing a surge in demand for portable power solutions, driven by the growing need for flexibility in various sectors. Industries such as construction, automotive, and maintenance require reliable power sources that can be easily transported to job sites. According to recent data, the market for portable generators is projected to grow at a compound annual growth rate of approximately 5.5% over the next few years. This trend indicates a robust appetite for portable welding generators, which offer the dual benefits of mobility and efficiency. As businesses seek to enhance productivity and reduce downtime, the adoption of portable welding generators is likely to increase, further propelling the market forward.

Technological Innovations in Welding Equipment

The Portable Welding Generators Market is benefiting from technological innovations in welding equipment, which are enhancing the performance and efficiency of portable generators. Advances in inverter technology, for instance, have led to lighter and more energy-efficient models that are easier to transport and operate. These innovations not only improve the user experience but also expand the range of applications for portable welding generators. As manufacturers continue to invest in research and development, the market is likely to see the introduction of more sophisticated models that meet the diverse needs of users. This trend suggests a promising future for the portable welding generators market as technology continues to evolve.