Rising Energy Demand

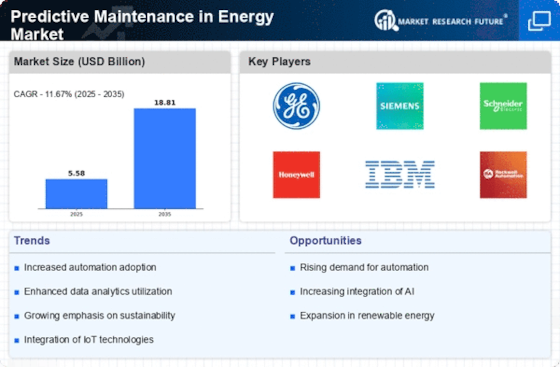

The rising demand for energy is a significant driver of the Predictive Maintenance in Energy Market. As populations grow and economies expand, the need for reliable energy sources intensifies. This increased demand places additional stress on existing energy infrastructure, making it imperative for companies to adopt predictive maintenance strategies. By utilizing predictive analytics, energy providers can optimize asset performance and extend the lifespan of critical equipment. Reports indicate that the global energy demand is projected to increase by 25% by 2040, underscoring the necessity for efficient maintenance practices. Consequently, the Predictive Maintenance in Energy Market is poised for growth as companies seek to enhance operational efficiency in response to this rising demand.

Integration of Artificial Intelligence

The integration of artificial intelligence (AI) into the Predictive Maintenance in Energy Market is transforming operational efficiencies. AI algorithms analyze vast amounts of data from sensors and equipment, identifying patterns that may indicate potential failures. This proactive approach reduces downtime and maintenance costs, as predictive models can forecast equipment failures before they occur. According to recent studies, organizations implementing AI-driven predictive maintenance strategies have reported a reduction in maintenance costs by up to 30%. As the energy sector increasingly adopts AI technologies, the Predictive Maintenance in Energy Market is likely to experience substantial growth, driven by the demand for smarter, more efficient energy management solutions.

Cost Reduction and Operational Efficiency

Cost reduction and operational efficiency are paramount concerns for organizations within the Predictive Maintenance in Energy Market. By implementing predictive maintenance strategies, companies can significantly lower their operational costs associated with unplanned downtime and emergency repairs. Studies indicate that predictive maintenance can reduce maintenance costs by up to 25% while improving equipment reliability. This financial incentive drives energy companies to invest in predictive maintenance technologies, as they seek to optimize their operations and enhance profitability. As the energy sector continues to evolve, the emphasis on cost-effective maintenance solutions will likely propel the growth of the Predictive Maintenance in Energy Market.

Regulatory Compliance and Safety Standards

Regulatory compliance and safety standards play a crucial role in shaping the Predictive Maintenance in Energy Market. Governments and regulatory bodies are increasingly mandating stringent safety protocols to ensure the reliability of energy infrastructure. Compliance with these regulations often necessitates the implementation of predictive maintenance strategies to monitor equipment health and performance. For instance, the U.S. Department of Energy has emphasized the importance of predictive maintenance in enhancing grid reliability and safety. As a result, energy companies are investing in predictive maintenance technologies to meet these regulatory requirements, thereby driving growth in the Predictive Maintenance in Energy Market.

Technological Advancements in Sensor Technologies

Technological advancements in sensor technologies are significantly influencing the Predictive Maintenance in Energy Market. The proliferation of advanced sensors enables real-time monitoring of equipment conditions, providing valuable data for predictive analytics. These sensors can detect anomalies in equipment performance, allowing for timely interventions before failures occur. The market for industrial sensors is expected to grow substantially, with estimates suggesting a compound annual growth rate of over 10% in the coming years. As energy companies increasingly adopt these technologies, the Predictive Maintenance in Energy Market is likely to benefit from enhanced data collection and analysis capabilities, leading to improved maintenance strategies.