Focus on Energy Efficiency

The Press Machine Market is witnessing a growing emphasis on energy efficiency as manufacturers strive to reduce operational costs and environmental impact. Energy-efficient press machines are becoming increasingly popular due to their ability to lower energy consumption while maintaining high performance. Recent studies indicate that energy-efficient models can reduce energy usage by up to 30%, which is a compelling factor for manufacturers aiming to enhance sustainability. As regulatory frameworks become more stringent regarding energy consumption and emissions, the demand for energy-efficient press machines is likely to increase. This shift not only aligns with The Press Machine Industry favorably in a competitive landscape where energy costs are a critical concern.

Rising Demand for Automation

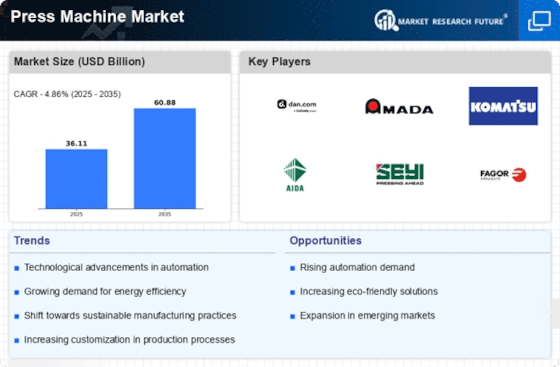

The Press Machine Market is experiencing a notable surge in demand for automation across various sectors. Industries such as automotive, aerospace, and electronics are increasingly adopting automated press machines to enhance production efficiency and reduce labor costs. According to recent data, the automation segment is projected to grow at a compound annual growth rate of approximately 7% over the next five years. This trend is driven by the need for precision and consistency in manufacturing processes, which automated press machines can provide. As manufacturers seek to optimize their operations, the integration of advanced technologies such as artificial intelligence and machine learning into press machines is likely to become more prevalent, further propelling the growth of the Press Machine Market.

Expansion of the Manufacturing Sector

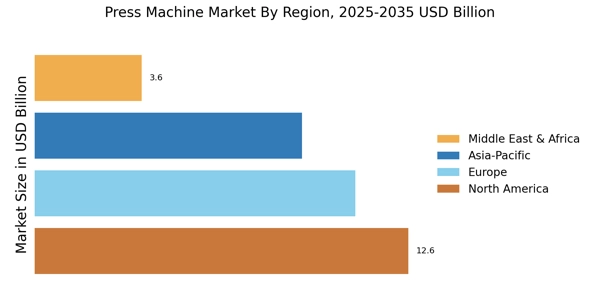

The Press Machine Market is benefiting from the expansion of the manufacturing sector, particularly in emerging economies. As countries invest in infrastructure and industrial development, the demand for press machines is expected to rise significantly. For instance, the manufacturing output in several regions has shown a steady increase, with projections indicating a growth rate of around 5% annually. This expansion is largely attributed to the increasing production of consumer goods, machinery, and automotive components. Consequently, manufacturers are compelled to upgrade their equipment, including press machines, to meet the growing production demands. This trend not only supports the Press Machine Market but also fosters innovation and technological advancements within the sector.

Increasing Customization Requirements

The Press Machine Market is adapting to the rising demand for customization in manufacturing processes. As consumer preferences shift towards personalized products, manufacturers are compelled to invest in press machines that offer greater flexibility and adaptability. This trend is particularly evident in industries such as consumer electronics and automotive, where tailored solutions are becoming the norm. Market analysis indicates that the customization segment is expected to grow at a rate of approximately 6% over the next few years. Manufacturers are increasingly seeking press machines that can accommodate various materials and production techniques, thereby enhancing their ability to meet diverse customer needs. This shift towards customization is likely to play a pivotal role in shaping the future of the Press Machine Market.

Technological Innovations in Press Machines

The Press Machine Market is significantly influenced by ongoing technological innovations that enhance machine capabilities and performance. Advancements such as servo-driven presses, hybrid systems, and smart manufacturing technologies are reshaping the landscape of press machines. These innovations enable manufacturers to achieve higher precision, faster cycle times, and improved flexibility in production processes. Data suggests that the adoption of smart technologies in press machines could lead to productivity increases of up to 20%. As manufacturers seek to remain competitive, the integration of these advanced technologies into press machines is likely to drive growth in the Press Machine Market, fostering a new era of manufacturing efficiency.

.png)