Rising Applications in Renewable Energy

The Pressure Vessel Composites Market is witnessing a rise in applications within the renewable energy sector, particularly in wind and solar energy systems. Composites are increasingly utilized in the construction of pressure vessels for energy storage and transportation, owing to their durability and resistance to environmental factors. The global push towards sustainable energy solutions is likely to enhance the demand for composite materials, with the market expected to expand significantly in the coming years. As renewable energy projects proliferate, the Pressure Vessel Composites Market stands to benefit from the increasing need for efficient and reliable pressure vessels.

Growing Investment in Oil and Gas Sector

Investment in the oil and gas sector is a critical driver for the Pressure Vessel Composites Market. As exploration and production activities expand, there is a heightened demand for pressure vessels that can withstand extreme conditions. Composites offer superior corrosion resistance and longevity, making them ideal for offshore and onshore applications. The oil and gas industry is projected to invest over USD 1 trillion in new projects by 2027, which could significantly boost the demand for composite pressure vessels. This trend suggests a promising outlook for the Pressure Vessel Composites Market as it aligns with the evolving needs of the energy sector.

Enhanced Safety Standards and Regulations

The Pressure Vessel Composites Market is increasingly influenced by enhanced safety standards and regulations. Governments and regulatory bodies are implementing stricter guidelines to ensure the safe operation of pressure vessels, particularly in high-risk industries such as chemicals and energy. Composites, with their superior mechanical properties and resistance to failure, are becoming the material of choice to meet these stringent requirements. As compliance becomes more critical, manufacturers are likely to invest in composite solutions that adhere to safety regulations. This trend is expected to drive growth in the Pressure Vessel Composites Market, as companies seek to enhance safety while maintaining operational efficiency.

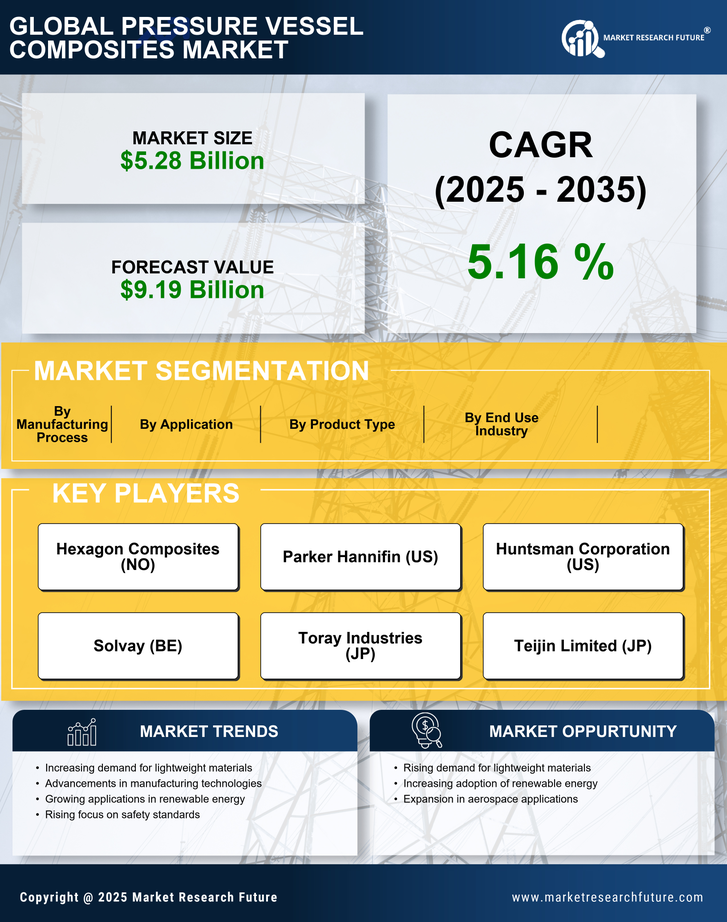

Increasing Demand for Lightweight Materials

The Pressure Vessel Composites Market is experiencing a notable surge in demand for lightweight materials, driven by the need for enhanced fuel efficiency and reduced emissions in various sectors, particularly in transportation and aerospace. Composites, known for their high strength-to-weight ratio, are increasingly favored over traditional materials like steel and aluminum. This shift is evidenced by the projected growth rate of the composites market, which is expected to reach USD 30 billion by 2026. As industries strive to meet stringent environmental regulations, the adoption of lightweight composite materials in pressure vessels is likely to accelerate, thereby propelling the Pressure Vessel Composites Market forward.

Advancements in Composite Manufacturing Technologies

Technological innovations in composite manufacturing are significantly influencing the Pressure Vessel Composites Market. Techniques such as automated fiber placement and resin transfer molding are enhancing production efficiency and reducing costs. These advancements allow for the creation of complex geometries and improved material properties, which are essential for high-performance pressure vessels. The market is projected to grow at a compound annual growth rate of 7% from 2025 to 2030, indicating a robust interest in advanced composite solutions. As manufacturers continue to invest in research and development, the Pressure Vessel Composites Market is poised for substantial growth, driven by these technological breakthroughs.