Regulatory Compliance

Regulatory frameworks are increasingly influencing the Radiation Curable Coating Market. Stricter regulations regarding VOC emissions and hazardous substances are prompting manufacturers to adopt radiation curable coatings, which typically comply with these standards. The coatings' ability to cure quickly and reduce waste aligns with regulatory goals aimed at minimizing environmental impact. As industries face mounting pressure to adhere to these regulations, the demand for compliant coatings is likely to rise. This trend is expected to drive market growth, with projections indicating that the market could expand significantly as more companies transition to radiation curable solutions to meet regulatory requirements.

Diverse Application Areas

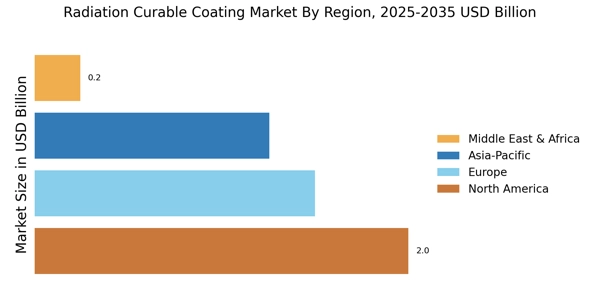

The versatility of radiation curable coatings is a significant driver in the Radiation Curable Coating Market. These coatings find applications across various sectors, including automotive, electronics, and packaging. Their ability to provide superior protection and aesthetic appeal makes them suitable for a wide range of products. For example, in the automotive sector, radiation curable coatings are utilized for their durability and resistance to chemicals and abrasion. The packaging industry also benefits from these coatings, as they enhance the shelf life of products while maintaining compliance with safety regulations. This broad applicability is expected to contribute to a steady growth trajectory, with the market anticipated to reach a valuation of several billion dollars in the coming years.

Technological Innovations

Technological advancements are playing a pivotal role in shaping the Radiation Curable Coating Market. Innovations in UV and electron beam curing technologies have enhanced the performance and efficiency of these coatings. For instance, the development of new photoinitiators and formulations has improved curing speed and adhesion properties, making radiation curable coatings more appealing to manufacturers. The market is witnessing a surge in research and development activities aimed at creating high-performance coatings that meet diverse application needs. As a result, the market is expected to experience robust growth, with estimates suggesting a potential increase in market size by over 20% in the next few years, driven by these technological breakthroughs.

Sustainability Initiatives

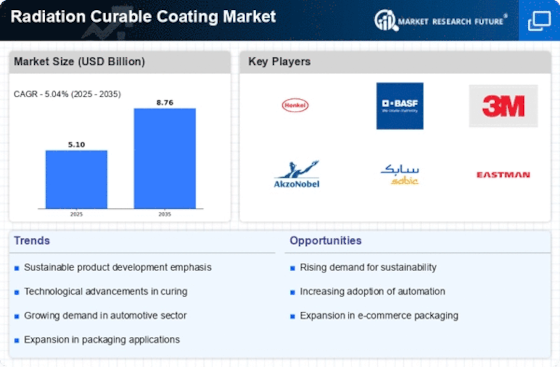

The increasing emphasis on sustainability within the Radiation Curable Coating Market is driving demand for eco-friendly products. Manufacturers are increasingly adopting radiation curable coatings due to their low volatile organic compound (VOC) emissions, which align with environmental regulations. This shift is evident as companies seek to reduce their carbon footprint and enhance their sustainability profiles. The market for radiation curable coatings is projected to grow at a compound annual growth rate (CAGR) of approximately 7% over the next five years, reflecting the rising preference for sustainable solutions. As industries prioritize green practices, the adoption of radiation curable coatings is likely to expand, further solidifying their role in sustainable manufacturing processes.

Economic Growth and Industrial Expansion

Economic growth and industrial expansion are key factors propelling the Radiation Curable Coating Market. As economies recover and industries expand, the demand for high-performance coatings is on the rise. The construction, automotive, and electronics sectors are particularly influential, as they require coatings that offer durability and aesthetic appeal. The market is poised for growth, with estimates suggesting that the demand for radiation curable coatings could increase by over 15% in the next few years, driven by industrial activities and infrastructure development. This economic momentum is likely to create new opportunities for manufacturers, further enhancing the market landscape.