Expansion of End-Use Industries

The expansion of various end-use industries, including packaging, electronics, and healthcare, is driving the growth of the reactive adhesives market. As these industries evolve, the demand for specialized adhesive solutions that cater to specific applications is increasing. The Reactive Adhesives Market is likely to benefit from this trend, as manufacturers seek adhesives that offer superior performance characteristics, such as heat resistance and chemical stability. In 2025, the packaging sector is projected to be a key contributor to market growth, with reactive adhesives being utilized for their excellent bonding properties and ability to enhance product integrity. This expansion across multiple sectors indicates a robust market potential for reactive adhesives, as they become integral to the production processes of diverse applications.

Growth in Construction Activities

The construction sector is witnessing robust growth, which is anticipated to drive the demand for reactive adhesives. As infrastructure projects expand, the need for durable and efficient bonding solutions becomes paramount. Reactive adhesives are favored for their ability to bond dissimilar materials, making them ideal for various construction applications, including flooring, roofing, and facades. In 2025, the construction industry is expected to significantly contribute to the reactive adhesives market, with a projected increase in market share. The Reactive Adhesives Market is likely to see heightened activity as builders and contractors prioritize high-performance adhesives that can withstand environmental stresses and enhance the longevity of structures. This trend indicates a shift towards more reliable and efficient construction practices, further solidifying the role of reactive adhesives in modern building projects.

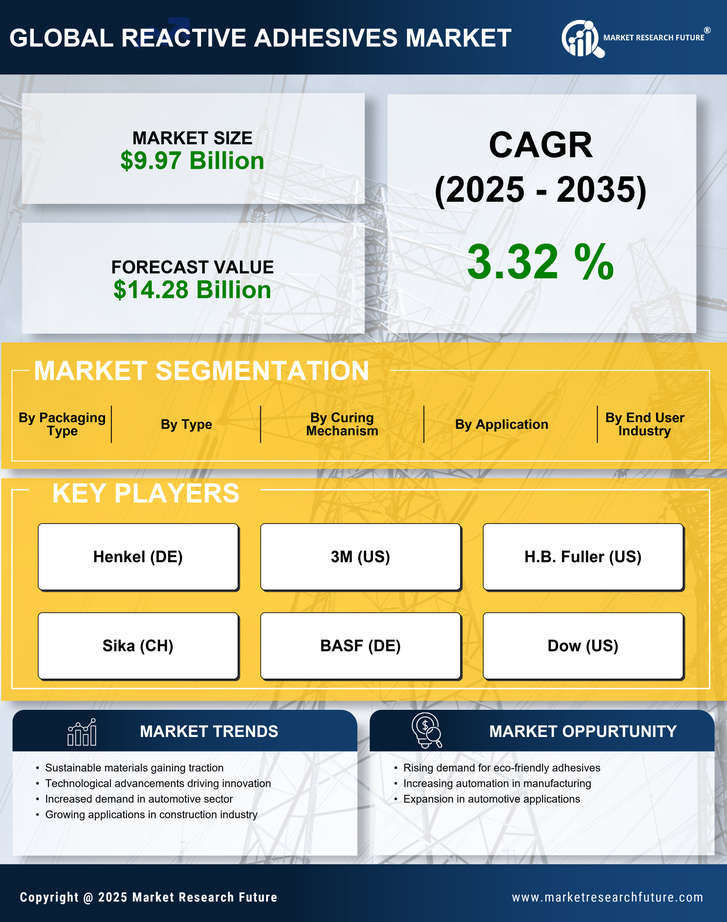

Rising Demand in Automotive Sector

The automotive industry is experiencing a notable surge in the use of reactive adhesives, driven by the need for lightweight materials and enhanced performance. Reactive adhesives provide superior bonding capabilities, which are essential for the assembly of various automotive components. In 2025, the automotive sector is projected to account for a significant share of the reactive adhesives market, as manufacturers increasingly adopt these adhesives to improve fuel efficiency and reduce emissions. The Reactive Adhesives Market is likely to benefit from this trend, as automotive manufacturers seek innovative solutions to meet stringent regulatory requirements and consumer preferences for sustainable vehicles. Furthermore, the integration of reactive adhesives in electric vehicles is expected to further propel market growth, as these vehicles require advanced bonding technologies to ensure structural integrity and safety.

Increasing Focus on Sustainable Practices

The emphasis on sustainability is becoming increasingly prominent across various industries, influencing the reactive adhesives market. Companies are actively seeking eco-friendly adhesive solutions that minimize environmental impact while maintaining performance standards. The Reactive Adhesives Market is responding to this demand by developing bio-based and low-VOC adhesives that align with sustainability goals. In 2025, the market is expected to see a rise in the adoption of these sustainable products, as regulatory pressures and consumer preferences shift towards greener alternatives. This trend not only enhances the market appeal of reactive adhesives but also encourages manufacturers to innovate and improve their product offerings, thereby fostering a more sustainable future for the industry.

Technological Innovations in Adhesive Formulations

Technological advancements in adhesive formulations are playing a crucial role in shaping the reactive adhesives market. Innovations such as the development of high-performance, eco-friendly adhesives are gaining traction, as manufacturers strive to meet evolving industry standards and consumer demands. The Reactive Adhesives Market is experiencing a transformation, with new formulations that offer improved bonding strength, faster curing times, and enhanced resistance to environmental factors. These innovations are particularly relevant in sectors such as aerospace and electronics, where precision and reliability are critical. As companies invest in research and development, the market is likely to witness the introduction of novel adhesive solutions that cater to specific applications, thereby expanding the overall market potential.