Regulatory Compliance

Regulatory compliance is a significant driver in the Rigid Foam Market. Governments worldwide are implementing stringent regulations regarding insulation materials, particularly concerning fire safety and environmental impact. Compliance with these regulations is essential for manufacturers to maintain market access and avoid penalties. As a result, companies are investing in research and development to create rigid foams that meet or exceed regulatory standards. This focus on compliance is expected to propel market growth, as products that adhere to safety and environmental guidelines are more likely to gain consumer trust. In 2025, the emphasis on regulatory compliance is likely to shape product offerings and influence purchasing decisions across various sectors.

Technological Innovations

Technological innovations play a pivotal role in shaping the Rigid Foam Market. Advancements in manufacturing processes, such as improved polymerization techniques, have led to the production of higher quality rigid foams. These innovations enhance thermal insulation properties and reduce production costs. The introduction of smart rigid foams, which can adapt to environmental changes, is also gaining traction. In 2025, the market for technologically advanced rigid foams is anticipated to account for a significant share, driven by the construction and automotive sectors. As industries seek to improve energy efficiency and reduce operational costs, the demand for innovative rigid foam solutions is likely to surge, fostering a competitive landscape.

Sustainability Initiatives

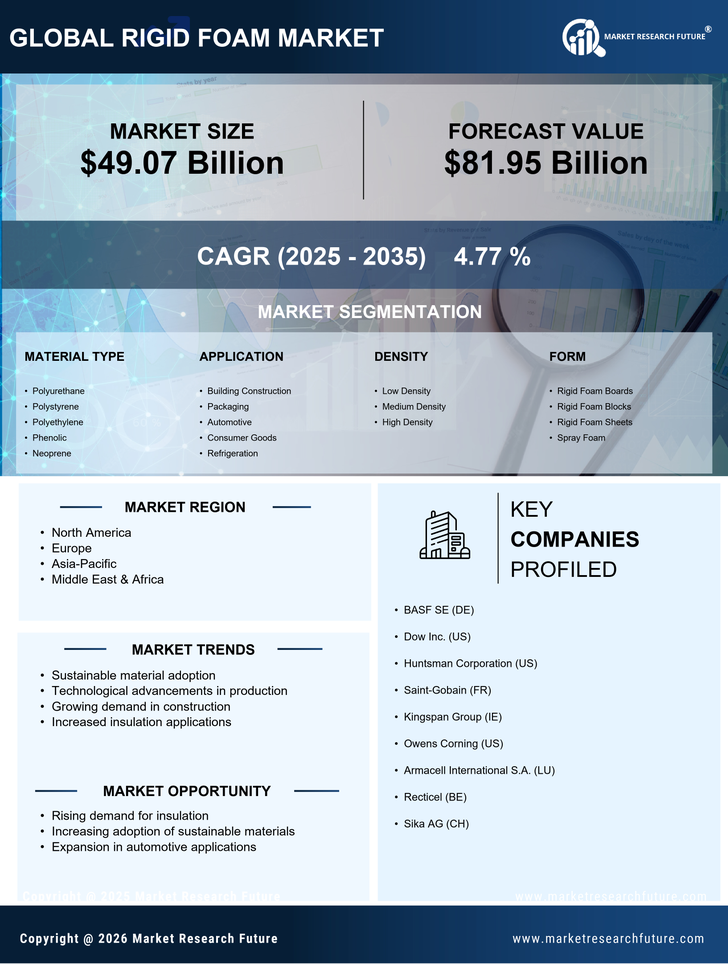

The Rigid Foam Market is increasingly influenced by sustainability initiatives. As environmental concerns rise, manufacturers are compelled to adopt eco-friendly practices. This includes the use of recyclable materials and the development of bio-based rigid foams. The market is projected to grow as consumers demand products that minimize environmental impact. In 2025, the market for sustainable rigid foams is expected to reach a valuation of approximately 15 billion dollars, reflecting a shift towards greener alternatives. Companies that prioritize sustainability may gain a competitive edge, appealing to environmentally conscious consumers and businesses alike. This trend not only enhances brand reputation but also aligns with regulatory pressures aimed at reducing carbon footprints.

Diverse End-Use Applications

The Rigid Foam Market benefits from diverse end-use applications across various sectors. Industries such as construction, automotive, and packaging are increasingly utilizing rigid foams for their superior insulation properties and lightweight characteristics. In the construction sector, rigid foams are employed in walls, roofs, and floors to enhance energy efficiency. The automotive industry utilizes these materials for lightweight components, contributing to fuel efficiency. In 2025, the construction sector is projected to dominate the rigid foam market, accounting for over 40% of the total demand. This diversification of applications not only drives market growth but also encourages innovation in product development, catering to specific industry needs.

Economic Growth and Urbanization

Economic growth and urbanization are driving forces in the Rigid Foam Market. As economies expand, there is an increased demand for construction and infrastructure development. Urbanization leads to a surge in residential and commercial building projects, which in turn boosts the demand for rigid foams used in insulation and structural applications. In 2025, the construction industry is expected to witness substantial growth, with rigid foams playing a crucial role in meeting energy efficiency standards. This trend is particularly evident in emerging markets, where rapid urbanization is creating opportunities for manufacturers. The interplay between economic growth and urbanization is likely to sustain demand for rigid foams, fostering a robust market environment.