Enhanced Quality Control

Quality assurance remains a critical focus within the Robotic Process Automation for Smartphone Manufacturing Market. Automation technologies facilitate consistent and precise quality control measures, which are essential in maintaining product standards. Robots equipped with advanced sensors and AI capabilities can detect defects and anomalies in real-time, significantly reducing the likelihood of faulty products reaching consumers. This capability not only enhances customer satisfaction but also minimizes costly recalls and warranty claims. As manufacturers increasingly prioritize quality, the integration of robotic systems is likely to become a standard practice, thereby driving growth in the automation sector.

Scalability of Production

The ability to scale production efficiently is a key driver in the Robotic Process Automation for Smartphone Manufacturing Market. As consumer demand fluctuates, manufacturers require flexible solutions that can adapt to varying production volumes. Robotic systems offer the scalability needed to increase or decrease output without the complexities associated with human labor adjustments. This flexibility is particularly advantageous during product launches or seasonal demand spikes. Moreover, the integration of automation allows for rapid reconfiguration of production lines, enabling manufacturers to respond swiftly to market changes, thus enhancing their competitive edge.

Labor Shortages and Skills Gap

The ongoing challenges related to labor shortages and skills gaps are propelling the adoption of robotic solutions in the Robotic Process Automation for Smartphone Manufacturing Market. As the workforce becomes increasingly difficult to source, manufacturers are turning to automation to fill critical roles and maintain production levels. Robots can perform repetitive tasks that are often unattractive to human workers, thus alleviating some of the pressure caused by labor shortages. This trend is expected to continue, as companies recognize the necessity of automation in sustaining operations and achieving long-term growth in a competitive landscape.

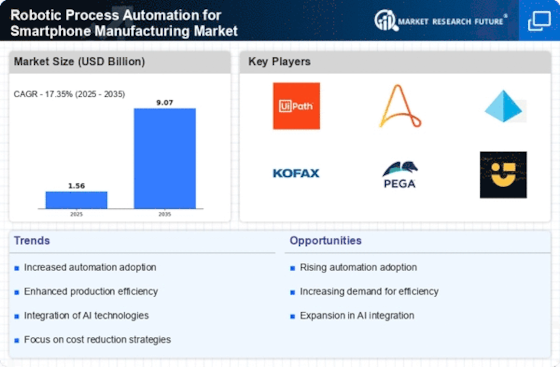

Cost Reduction through Automation

The Robotic Process Automation for Smartphone Manufacturing Market is witnessing a pronounced shift towards automation as manufacturers seek to reduce operational costs. By implementing robotic solutions, companies can minimize labor costs, which traditionally account for a significant portion of production expenses. Automation technologies can streamline processes, reduce errors, and enhance productivity, leading to an estimated 20-30% reduction in manufacturing costs. This financial incentive is compelling, as firms aim to maintain competitive pricing in a saturated market. Furthermore, the initial investment in robotic systems is often offset by long-term savings, making it a strategic choice for manufacturers looking to optimize their financial performance.

Integration of Advanced Technologies

The convergence of advanced technologies such as artificial intelligence, machine learning, and the Internet of Things is significantly influencing the Robotic Process Automation for Smartphone Manufacturing Market. These technologies enhance the capabilities of robotic systems, allowing for smarter decision-making and improved operational efficiency. For instance, AI-driven robots can analyze production data to optimize workflows and predict maintenance needs, thereby reducing downtime. This integration not only boosts productivity but also fosters innovation in manufacturing processes, positioning companies at the forefront of technological advancement in the smartphone sector.