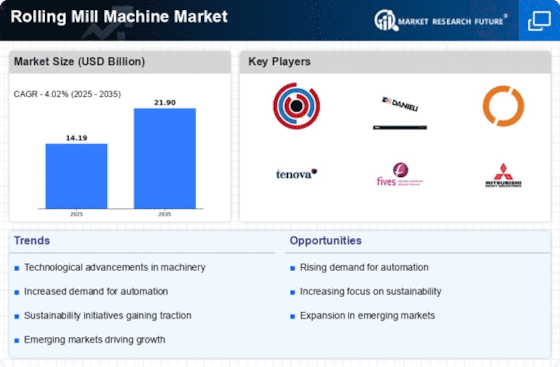

Focus on Energy Efficiency

The Rolling Mill Machine Market is witnessing a growing emphasis on energy efficiency and sustainability. Manufacturers are increasingly seeking rolling mill machines that consume less energy and produce lower emissions. This shift is driven by regulatory pressures and a societal push towards greener manufacturing practices. Recent data indicates that energy-efficient rolling mills can reduce energy consumption by up to 30%, making them an attractive option for producers. As companies strive to enhance their environmental credentials, the demand for energy-efficient rolling mill machines is likely to increase, thereby propelling market growth.

Technological Advancements

The Rolling Mill Machine Market is experiencing a surge in technological advancements, which are enhancing the efficiency and productivity of rolling mills. Innovations such as advanced automation, artificial intelligence, and machine learning are being integrated into rolling mill operations. These technologies enable real-time monitoring and predictive maintenance, reducing downtime and operational costs. According to recent data, the adoption of smart manufacturing solutions is projected to increase by 25% over the next five years, indicating a strong trend towards modernization in the industry. As manufacturers seek to optimize their processes, the demand for advanced rolling mill machines is likely to rise, driving growth in the market.

Rising Demand for Steel Products

The Rolling Mill Machine Market is significantly influenced by the rising demand for steel products across various sectors, including construction, automotive, and manufacturing. As urbanization and industrialization continue to expand, the need for high-quality steel is expected to grow. Recent statistics suggest that the global steel consumption is anticipated to reach 1.8 billion tons by 2026, which could lead to an increased requirement for rolling mill machines to produce the necessary steel components. This growing demand presents a substantial opportunity for manufacturers in the rolling mill machine sector, as they strive to meet the evolving needs of the market.

Investment in Infrastructure Development

The Rolling Mill Machine Market is poised to benefit from increased investment in infrastructure development projects worldwide. Governments and private entities are allocating substantial budgets for infrastructure improvements, including roads, bridges, and buildings. This trend is likely to drive the demand for steel, which in turn necessitates the use of rolling mill machines for production. For instance, recent reports indicate that infrastructure spending is projected to grow by 10% annually over the next five years, creating a favorable environment for rolling mill machine manufacturers. As infrastructure projects ramp up, the market for rolling mill machines is expected to expand correspondingly.

Customization and Product Diversification

The Rolling Mill Machine Market is characterized by a trend towards customization and product diversification. As industries evolve, there is a growing need for rolling mill machines that can produce a wider variety of products with specific characteristics. This demand for tailored solutions is prompting manufacturers to innovate and develop machines that can accommodate diverse specifications. Recent market analysis suggests that the customization segment is expected to grow by 15% over the next few years, reflecting the industry's response to changing customer needs. This focus on customization is likely to drive competition and innovation within the rolling mill machine market.