Diverse Application Areas

The Rotary Vane Vacuum Pump Market benefits from its diverse application areas, which span across multiple sectors including automotive, food and beverage, and chemical processing. The versatility of rotary vane vacuum pumps allows them to be utilized in various processes such as packaging, drying, and material handling. This adaptability is a key driver of market growth, as industries seek reliable vacuum solutions that can meet specific operational needs. Recent trends indicate that the food and beverage sector is increasingly adopting rotary vane vacuum pumps for packaging applications, enhancing product shelf life and quality. As industries continue to explore innovative applications for vacuum technology, the demand for rotary vane vacuum pumps is likely to expand, further solidifying their role in modern manufacturing processes.

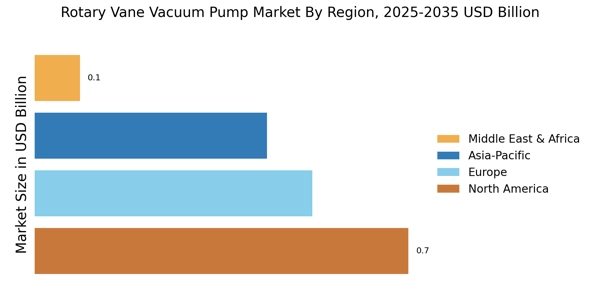

Expansion in Emerging Markets

The Rotary Vane Vacuum Pump Market is poised for growth due to the expansion in emerging markets. Countries in Asia-Pacific and Latin America are experiencing rapid industrialization, leading to increased demand for vacuum solutions across various sectors. The automotive, electronics, and food processing industries in these regions are particularly reliant on rotary vane vacuum pumps for their operational processes. Market data suggests that the Asia-Pacific region alone is expected to account for a significant share of the rotary vane vacuum pump market by 2026, driven by rising manufacturing activities and investments in infrastructure. This expansion presents opportunities for manufacturers to establish a foothold in these markets, catering to the growing needs of diverse industries.

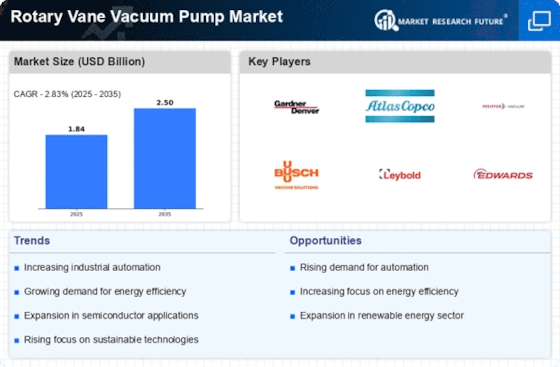

Increased Focus on Energy Efficiency

The Rotary Vane Vacuum Pump Market is witnessing an increased focus on energy efficiency, driven by both regulatory pressures and corporate sustainability goals. Companies are actively seeking vacuum solutions that not only meet operational requirements but also minimize energy consumption. Rotary vane vacuum pumps, known for their efficiency, are becoming a preferred choice as they can significantly reduce energy costs compared to traditional vacuum systems. According to recent studies, energy-efficient pumps can lead to savings of up to 30% in operational costs. This trend is particularly relevant in industries such as manufacturing and food processing, where energy costs constitute a substantial portion of overall expenses. As organizations strive to meet sustainability targets, the demand for energy-efficient rotary vane vacuum pumps is expected to grow.

Growing Demand from the Pharmaceutical Sector

The Rotary Vane Vacuum Pump Market is significantly driven by the growing demand from the pharmaceutical sector. As the industry expands, the need for reliable vacuum systems for processes such as freeze-drying, distillation, and filtration becomes paramount. Rotary vane vacuum pumps are favored for their ability to provide consistent vacuum levels, which is essential for maintaining product quality and safety. Recent data indicates that the pharmaceutical industry is projected to grow at a compound annual growth rate of over 5% in the coming years, further fueling the demand for rotary vane vacuum pumps. This growth is likely to create opportunities for manufacturers to develop specialized pumps tailored to the unique requirements of pharmaceutical applications, thereby enhancing their market presence.

Technological Advancements in Rotary Vane Vacuum Pumps

The Rotary Vane Vacuum Pump Market is experiencing a surge in technological advancements that enhance performance and efficiency. Innovations such as improved materials and design modifications are leading to pumps that operate at lower noise levels and higher energy efficiency. For instance, the integration of smart technology allows for real-time monitoring and predictive maintenance, reducing downtime and operational costs. As industries increasingly prioritize automation, the demand for advanced rotary vane vacuum pumps is likely to rise. Furthermore, the introduction of variable speed drives is enabling better control over vacuum levels, which is crucial for applications in sectors like pharmaceuticals and food processing. This trend suggests that companies investing in R&D for rotary vane vacuum pumps may gain a competitive edge in the market.