Rising Demand for Lightweight Materials

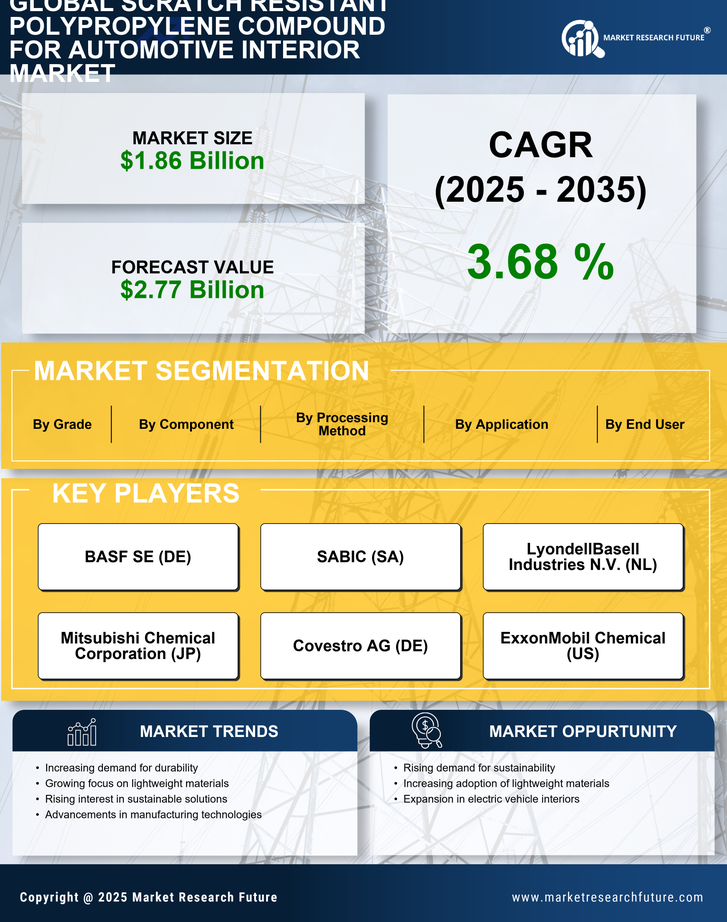

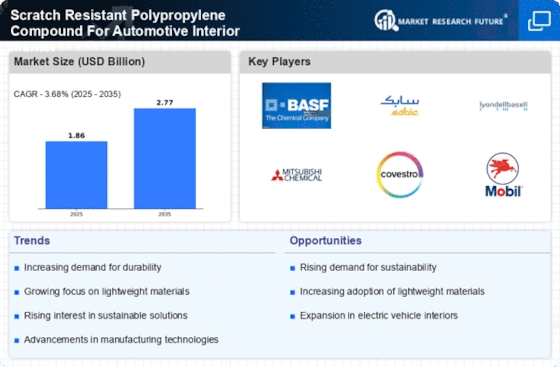

The automotive industry is increasingly focused on reducing vehicle weight to enhance fuel efficiency and performance. Scratch Resistant Polypropylene Compound For Automotive Interior Market is well-positioned to meet this demand due to its lightweight properties. As manufacturers seek to comply with stringent emissions regulations, the adoption of lightweight materials has surged. In 2025, it is estimated that the use of polypropylene compounds in automotive interiors will grow by approximately 15%, driven by the need for improved fuel economy. This trend indicates a shift towards materials that not only reduce weight but also provide durability and aesthetic appeal, making scratch resistant polypropylene compounds a preferred choice for interior applications.

Consumer Preference for Durable Interiors

As consumers become more discerning about the quality and longevity of automotive interiors, the demand for durable materials has intensified. Scratch Resistant Polypropylene Compound For Automotive Interior Market caters to this need by offering enhanced resistance to scratches and wear. This durability is particularly appealing in the context of increasing vehicle usage and the desire for long-lasting aesthetics. Market data suggests that the preference for durable interior materials is expected to drive a 20% increase in the adoption of polypropylene compounds by 2026. This shift reflects a broader trend towards investing in high-quality materials that can withstand the rigors of daily use while maintaining visual appeal.

Sustainability and Eco-Friendly Practices

The automotive sector is increasingly prioritizing sustainability, leading to a growing interest in eco-friendly materials. Scratch Resistant Polypropylene Compound For Automotive Interior Market aligns with this trend by offering recyclable and environmentally friendly options. As manufacturers strive to reduce their carbon footprint, the demand for sustainable materials is expected to rise significantly. By 2026, it is anticipated that the market for sustainable automotive interior materials will expand by 25%, driven by consumer preferences for greener products. This shift not only supports environmental initiatives but also enhances brand reputation, making scratch resistant polypropylene compounds an attractive choice for manufacturers.

Customization Trends in Automotive Interiors

The trend towards customization in automotive interiors is reshaping consumer expectations and driving demand for versatile materials. Scratch Resistant Polypropylene Compound For Automotive Interior Market is particularly suited to meet these customization needs, as it can be easily molded and colored to fit various design specifications. As consumers increasingly seek personalized vehicle interiors, the market for customizable materials is projected to grow by 18% by 2026. This trend highlights the importance of flexibility in material selection, allowing manufacturers to cater to diverse consumer preferences while maintaining the durability and aesthetic qualities that scratch resistant polypropylene compounds offer.

Technological Innovations in Material Science

Advancements in material science have led to the development of innovative scratch resistant polypropylene compounds that offer superior performance characteristics. The Scratch Resistant Polypropylene Compound For Automotive Interior Market benefits from these technological innovations, which enhance the material's resistance to scratches, UV degradation, and chemical exposure. In 2025, it is projected that the introduction of new formulations and processing techniques will result in a 10% increase in market share for these advanced materials. This growth is indicative of the industry's commitment to improving product quality and meeting the evolving needs of consumers and manufacturers alike.