Growing Focus on Sustainability

Sustainability is becoming an increasingly critical driver in the Semi-Automatic and Manual Filling Equipment Market. As consumers become more environmentally conscious, companies are compelled to adopt sustainable practices throughout their production processes. This includes the use of filling equipment that minimizes waste and energy consumption. Semi-automatic and manual filling systems often allow for more precise control over material usage, which can lead to reduced waste. Additionally, manufacturers are exploring eco-friendly materials and designs for their equipment, further aligning with sustainability goals. The emphasis on sustainable practices is likely to influence purchasing decisions, as businesses seek to enhance their brand image and meet consumer expectations.

Increased Regulatory Compliance

The Semi-Automatic and Manual Filling Equipment Market is influenced by the heightened focus on regulatory compliance across various sectors. Industries such as pharmaceuticals and food processing are subject to stringent regulations that govern product safety and quality. As companies strive to meet these standards, the demand for reliable filling equipment that ensures accuracy and consistency in production processes is amplified. Semi-automatic and manual filling equipment often provides the necessary control and oversight to comply with these regulations. For instance, the ability to adjust filling volumes and monitor processes closely can help businesses adhere to quality assurance protocols. This trend is expected to drive growth in the market as companies prioritize compliance in their operational strategies.

Cost-Effectiveness of Manual Solutions

In the Semi-Automatic and Manual Filling Equipment Market, the cost-effectiveness of manual solutions is a significant driver. Many small to medium-sized enterprises (SMEs) often face budget constraints that limit their ability to invest in fully automated systems. Manual filling equipment provides a viable alternative, allowing these businesses to maintain operational efficiency without incurring substantial capital expenditures. The initial investment for manual systems is considerably lower, making them accessible for startups and smaller operations. Furthermore, the operational costs associated with maintenance and training are also reduced, as manual systems typically require less complex upkeep. This financial advantage is likely to sustain the demand for manual filling solutions in the market.

Rising Demand for Small Batch Production

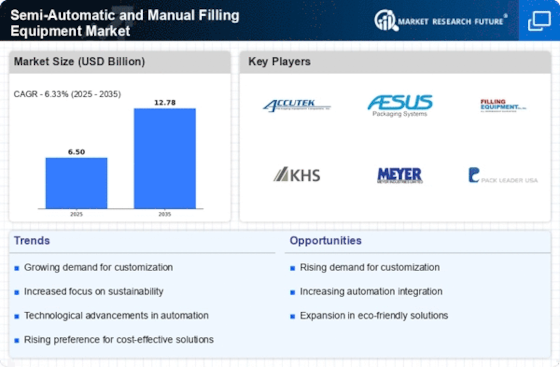

The Semi-Automatic and Manual Filling Equipment Market is experiencing a notable increase in demand for small batch production. This trend is largely driven by the growing preference for artisanal and niche products across various sectors, including food and beverage, cosmetics, and pharmaceuticals. As businesses seek to cater to specific consumer preferences, the need for equipment that can efficiently handle smaller quantities becomes paramount. According to recent data, the market for small batch production is projected to grow at a compound annual growth rate of approximately 6.5% over the next five years. This shift towards smaller production runs necessitates the adoption of semi-automatic and manual filling equipment, which offers the flexibility and precision required for such operations.

Technological Integration and Automation

The Semi-Automatic and Manual Filling Equipment Market is witnessing a trend towards the integration of advanced technologies into filling processes. While manual and semi-automatic systems are traditionally viewed as less sophisticated, the incorporation of smart technologies, such as sensors and data analytics, is enhancing their functionality. This integration allows for improved accuracy, reduced waste, and better tracking of production metrics. As manufacturers seek to optimize their operations, the demand for equipment that combines manual control with technological enhancements is likely to rise. This trend not only improves efficiency but also aligns with the broader industry movement towards Industry 4.0, where automation and data exchange are paramount.

.png)