Focus on Cost Efficiency

Cost efficiency remains a pivotal driver in the Sheet Metal Fabrication Equipment Market. Manufacturers are under constant pressure to optimize their production processes and reduce waste. The integration of energy-efficient machines and lean manufacturing principles is becoming commonplace, as companies strive to lower operational costs. Reports indicate that businesses adopting these strategies can achieve cost reductions of up to 20%. This focus on cost efficiency not only enhances profitability but also encourages investment in advanced fabrication technologies, further stimulating growth in the Sheet Metal Fabrication Equipment Market.

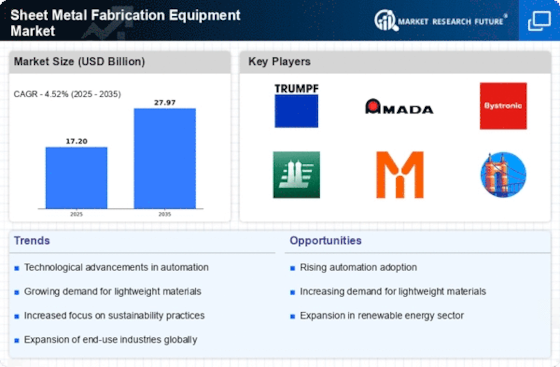

Technological Advancements

The Sheet Metal Fabrication Equipment Market is experiencing a surge in technological advancements, particularly in automation and precision engineering. Innovations such as laser cutting, CNC machining, and robotic welding are enhancing production efficiency and accuracy. According to recent data, the adoption of advanced technologies is projected to increase productivity by up to 30% in the next few years. This trend not only reduces operational costs but also meets the growing demand for high-quality fabricated products. As manufacturers seek to remain competitive, investing in state-of-the-art equipment becomes imperative, thereby driving growth in the Sheet Metal Fabrication Equipment Market.

Growing Emphasis on Sustainability

Sustainability is becoming a crucial consideration in the Sheet Metal Fabrication Equipment Market. As environmental regulations tighten and consumer preferences shift towards eco-friendly products, manufacturers are increasingly adopting sustainable practices. This includes utilizing recyclable materials and energy-efficient processes in fabrication. The market is witnessing a shift towards equipment that minimizes waste and reduces carbon footprints. Data suggests that companies implementing sustainable practices can enhance their market competitiveness and appeal to environmentally conscious consumers. This growing emphasis on sustainability is likely to drive innovation and investment in the Sheet Metal Fabrication Equipment Market.

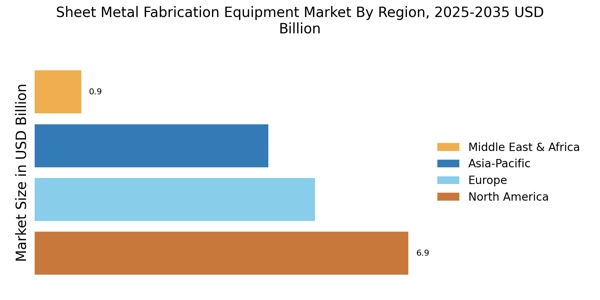

Increased Investment in Infrastructure

The Sheet Metal Fabrication Equipment Market is benefiting from increased investment in infrastructure projects worldwide. Governments and private entities are allocating substantial budgets for the development of roads, bridges, and buildings, which in turn drives the demand for fabricated metal components. This trend is expected to continue, with infrastructure spending projected to rise significantly over the next few years. As a result, manufacturers are likely to ramp up production capabilities, leading to a heightened demand for advanced sheet metal fabrication equipment. This investment climate presents a favorable environment for growth in the Sheet Metal Fabrication Equipment Market.

Rising Demand from End-User Industries

The Sheet Metal Fabrication Equipment Market is significantly influenced by the rising demand from various end-user sectors, including automotive, aerospace, and construction. These industries are increasingly relying on fabricated metal components for their products, leading to a robust market for fabrication equipment. For instance, the automotive sector alone is expected to account for a substantial share of the market, driven by the need for lightweight and durable materials. As these industries expand, the demand for efficient and versatile sheet metal fabrication equipment is likely to grow, propelling the market forward.

.png)