Increasing Focus on Sustainability

The Shell Tube Heat Exchanger Market is witnessing a paradigm shift towards sustainability, driven by the growing awareness of environmental issues. Industries are increasingly adopting heat exchangers that minimize energy consumption and reduce greenhouse gas emissions. This trend is particularly evident in sectors such as HVAC, where energy-efficient systems are becoming a standard requirement. Furthermore, the implementation of circular economy principles is prompting manufacturers to design heat exchangers that are easier to recycle and have a lower environmental impact. As sustainability becomes a core business strategy, the Shell Tube Heat Exchanger Market is expected to see a rise in demand for eco-friendly solutions that align with corporate social responsibility goals.

Rising Energy Efficiency Standards

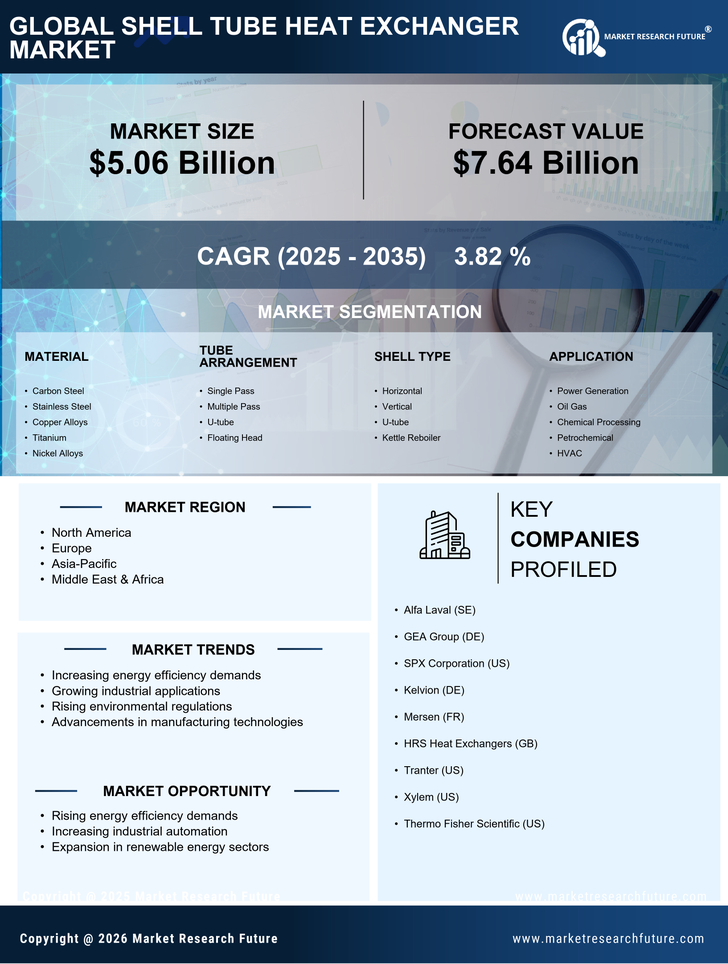

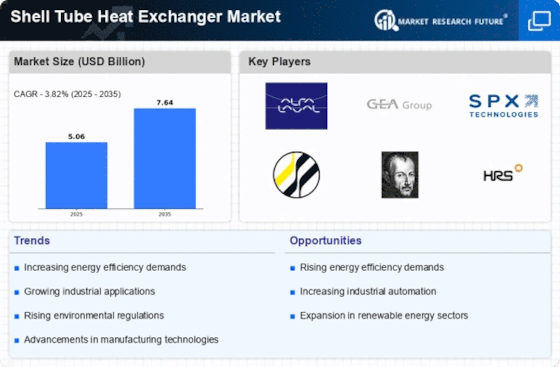

The Shell Tube Heat Exchanger Market is experiencing a notable shift towards enhanced energy efficiency standards. Governments and regulatory bodies are increasingly mandating stricter energy consumption regulations across various sectors, including manufacturing and power generation. This trend compels industries to adopt advanced heat exchanger technologies that optimize thermal performance while minimizing energy waste. As a result, manufacturers are investing in innovative designs and materials that improve heat transfer efficiency. The market is projected to witness a compound annual growth rate of approximately 5.2% over the next five years, driven by the need for compliance with these energy efficiency standards. Consequently, the Shell Tube Heat Exchanger Market is likely to expand as companies seek to upgrade their systems to meet these evolving requirements.

Expansion of Renewable Energy Sector

The Shell Tube Heat Exchanger Market is poised for growth due to the expansion of the renewable energy sector. As countries invest in alternative energy sources such as solar, wind, and biomass, the need for efficient thermal management systems becomes increasingly critical. Shell tube heat exchangers play a vital role in various renewable energy applications, including concentrated solar power plants and biomass energy facilities. Recent projections suggest that the renewable energy sector will grow at a rate of 8% annually, creating substantial opportunities for the Shell Tube Heat Exchanger Market. This growth is likely to be fueled by the global transition towards cleaner energy solutions, prompting manufacturers to innovate and adapt their products to meet the specific needs of this evolving market.

Growing Demand in Oil and Gas Sector

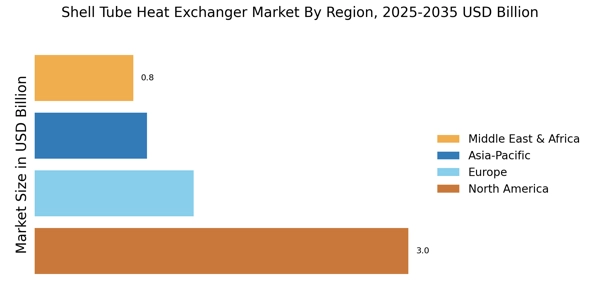

The Shell Tube Heat Exchanger Market is significantly influenced by the burgeoning demand from the oil and gas sector. As exploration and production activities intensify, there is an increasing need for efficient heat exchange solutions to manage thermal processes in refineries and petrochemical plants. Shell tube heat exchangers are particularly favored for their robustness and ability to handle high-pressure applications. Recent data indicates that the oil and gas industry accounts for nearly 40% of the total demand for heat exchangers, underscoring the critical role of this sector in driving market growth. The Shell Tube Heat Exchanger Market is poised for expansion as companies invest in upgrading their facilities to enhance operational efficiency and reduce downtime.

Technological Innovations in Heat Exchanger Design

Technological innovations are reshaping the Shell Tube Heat Exchanger Market, as manufacturers strive to develop more efficient and compact designs. Advances in materials science and computational fluid dynamics are enabling the creation of heat exchangers that offer superior performance while occupying less space. These innovations not only enhance heat transfer rates but also contribute to reduced maintenance costs and longer service life. The integration of smart technologies, such as IoT sensors, is further optimizing the operational efficiency of shell tube heat exchangers. As industries increasingly prioritize performance and reliability, the Shell Tube Heat Exchanger Market is likely to benefit from these technological advancements, fostering a competitive landscape that encourages continuous improvement.