Rising Demand for Eco-Friendly Products

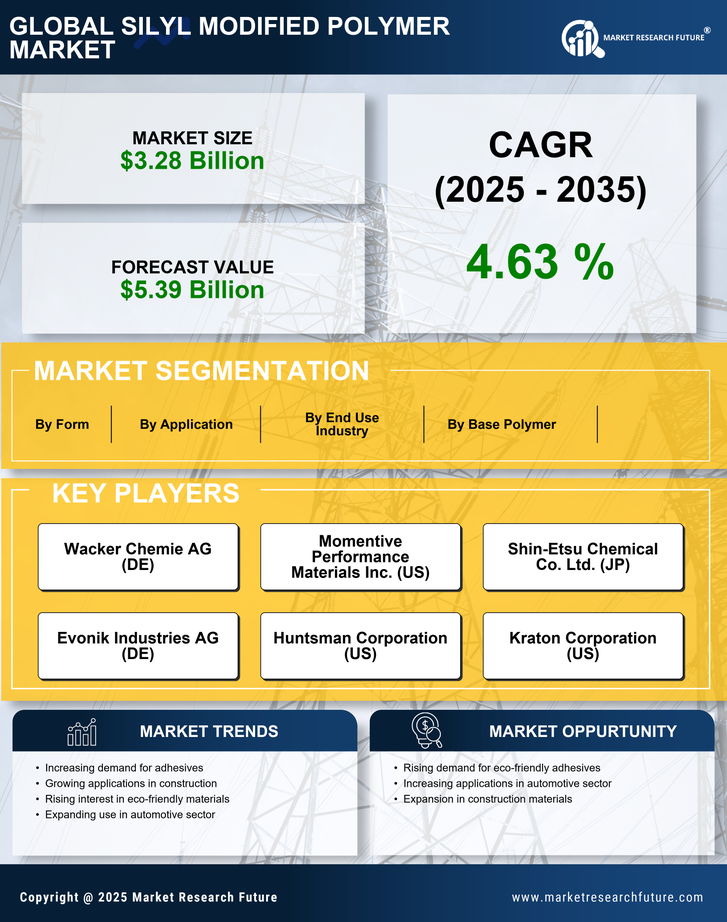

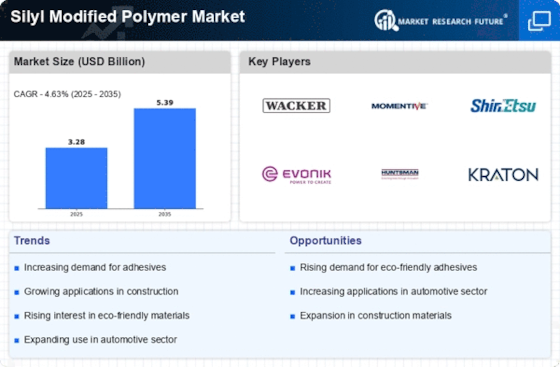

The Silyl Modified Polymer Market is experiencing a notable increase in demand for eco-friendly products. As consumers and manufacturers alike become more environmentally conscious, the shift towards sustainable materials is evident. Silyl modified polymers, known for their low VOC emissions and biodegradability, align well with this trend. Market data indicates that the demand for sustainable construction materials is projected to grow at a CAGR of 8% over the next five years. This growth is likely to drive the adoption of silyl modified polymers in various applications, including adhesives, sealants, and coatings, thereby enhancing their market presence.

Growth in the Adhesives and Sealants Market

The Silyl Modified Polymer Market is closely linked to the growth of the adhesives and sealants market. As industries seek more efficient and durable bonding solutions, the demand for silyl modified polymers is expected to rise. These polymers offer excellent adhesion properties and are resistant to moisture and temperature fluctuations, making them ideal for various applications. Recent market reports suggest that the adhesives and sealants market is projected to grow at a CAGR of 6% through 2028. This growth is likely to drive the demand for silyl modified polymers, as manufacturers increasingly incorporate them into their product formulations to meet evolving industry standards.

Regulatory Support for Sustainable Materials

Regulatory frameworks promoting the use of sustainable materials are playing a crucial role in shaping the Silyl Modified Polymer Market. Governments worldwide are implementing stringent regulations aimed at reducing environmental impact, which encourages manufacturers to adopt eco-friendly alternatives. Silyl modified polymers, with their favorable environmental profile, are well-positioned to benefit from these regulations. For instance, initiatives aimed at reducing plastic waste and promoting recycling are likely to enhance the market prospects for silyl modified polymers. It is anticipated that compliance with these regulations could lead to a 20% increase in market demand over the next few years.

Technological Innovations in Polymer Chemistry

Technological advancements in polymer chemistry are significantly influencing the Silyl Modified Polymer Market. Innovations such as improved synthesis methods and enhanced formulation techniques are enabling manufacturers to develop high-performance silyl modified polymers. These advancements not only improve the mechanical properties and durability of the polymers but also expand their applicability across various sectors. For instance, the introduction of new curing agents and additives has led to the creation of products that exhibit superior adhesion and weather resistance. Market analysis suggests that these innovations could potentially increase the market share of silyl modified polymers by 15% in the next few years.

Expanding Applications in Construction and Automotive

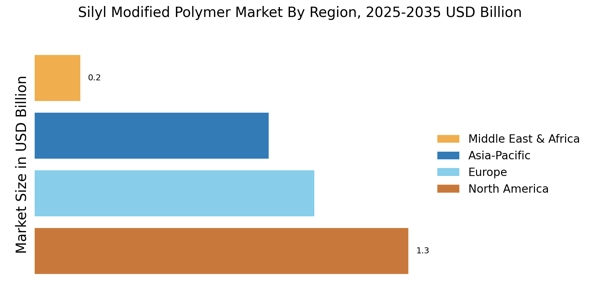

The Silyl Modified Polymer Market is witnessing an expansion in applications, particularly in the construction and automotive sectors. The versatility of silyl modified polymers makes them suitable for a wide range of uses, including sealants, adhesives, and coatings. In the construction sector, the increasing focus on energy-efficient buildings is driving the demand for high-performance sealants that can withstand extreme weather conditions. Similarly, in the automotive industry, the need for lightweight and durable materials is propelling the adoption of silyl modified polymers. Recent market data indicates that the construction sector alone accounts for approximately 40% of the total demand for silyl modified polymers.