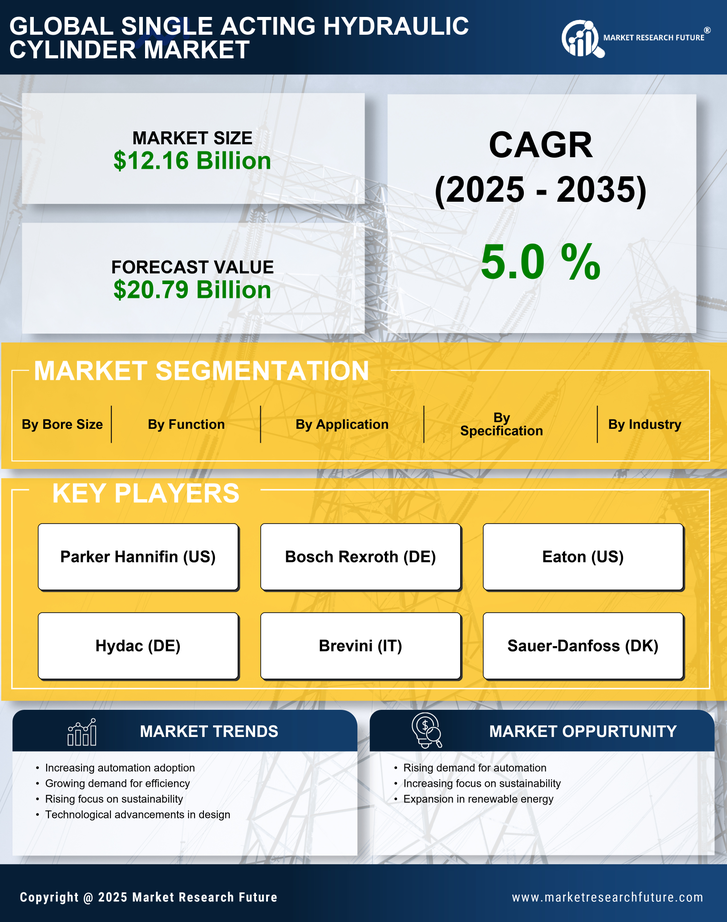

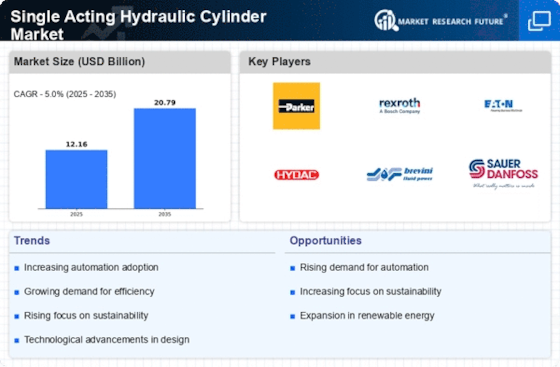

Rising Demand in Construction Sector

The construction sector is experiencing a notable surge in demand for single acting hydraulic cylinders, driven by ongoing infrastructure projects and urban development initiatives. As cities expand and new buildings emerge, the need for efficient lifting and pushing mechanisms becomes paramount. The single acting hydraulic cylinder market is poised to benefit from this trend, as these cylinders are integral to various construction equipment, including cranes and excavators. Recent data indicates that the construction industry is projected to grow at a compound annual growth rate of approximately 5.5% over the next few years, further solidifying the role of single acting hydraulic cylinders in meeting the operational demands of this sector.

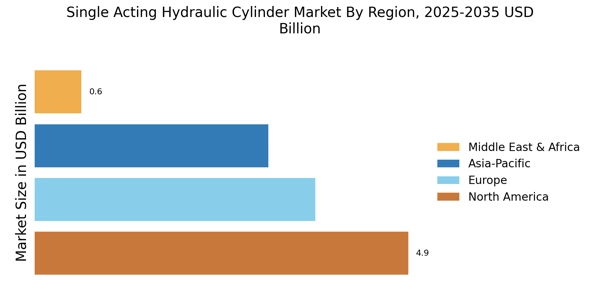

Expansion of Renewable Energy Projects

The expansion of renewable energy projects is creating new opportunities for the single acting hydraulic cylinder market. As countries invest in wind, solar, and hydroelectric power, the need for hydraulic systems in energy generation and maintenance becomes increasingly apparent. Single acting hydraulic cylinders are utilized in various applications, such as adjusting solar panels and operating wind turbine mechanisms. The renewable energy sector is projected to grow significantly, with estimates suggesting an annual growth rate of around 10%. This trend indicates a robust demand for hydraulic solutions that can support the infrastructure of renewable energy projects, positioning single acting hydraulic cylinders as vital components in this evolving industry.

Growing Focus on Automation in Manufacturing

The manufacturing sector is increasingly focusing on automation, which is driving the demand for single acting hydraulic cylinders. These cylinders play a crucial role in automated systems, providing reliable force and motion control in various manufacturing processes. The single acting hydraulic cylinder market is likely to benefit from this trend as manufacturers seek to enhance productivity and efficiency. Recent reports suggest that the automation market is expected to grow at a rate of approximately 8% per year, indicating a strong potential for hydraulic solutions that can seamlessly integrate into automated environments. This shift towards automation underscores the importance of hydraulic cylinders in modern manufacturing.

Increased Adoption in Agricultural Machinery

The agricultural sector is increasingly adopting single acting hydraulic cylinders to enhance the efficiency of machinery used in farming operations. These cylinders are essential for various applications, such as lifting and tilting equipment, which are crucial for modern agricultural practices. The single acting hydraulic cylinder market is likely to see growth as farmers seek to improve productivity and reduce labor costs. According to recent statistics, the agricultural machinery market is expected to expand significantly, with a projected growth rate of around 4% annually. This trend suggests a robust demand for hydraulic solutions that can support the evolving needs of the agricultural landscape.

Technological Innovations in Hydraulic Systems

Technological innovations are reshaping the landscape of the single acting hydraulic cylinder market. Advancements in materials and design are leading to the development of more efficient and durable hydraulic cylinders. Innovations such as smart hydraulic systems, which integrate IoT technology, are enhancing operational efficiency and monitoring capabilities. This trend is particularly relevant as industries seek to optimize performance and reduce maintenance costs. The market for hydraulic systems is anticipated to grow, with estimates suggesting a value increase of over 6% annually. Such advancements indicate a promising future for single acting hydraulic cylinders as they adapt to the demands of modern applications.