Focus on Cost-Effective Solutions

Cost efficiency remains a critical driver in the SMC and BMC Market, as manufacturers seek to optimize production while maintaining quality. The rising costs of raw materials have prompted companies to explore more economical alternatives, leading to increased interest in SMC and BMC composites. These materials not only offer competitive pricing but also provide superior performance characteristics, making them attractive to various industries. The emphasis on cost-effective solutions is likely to stimulate market growth, with projections suggesting that the SMC and BMC Market could expand by approximately 10% annually as businesses prioritize budget-friendly options without compromising on quality.

Rising Demand for Lightweight Materials

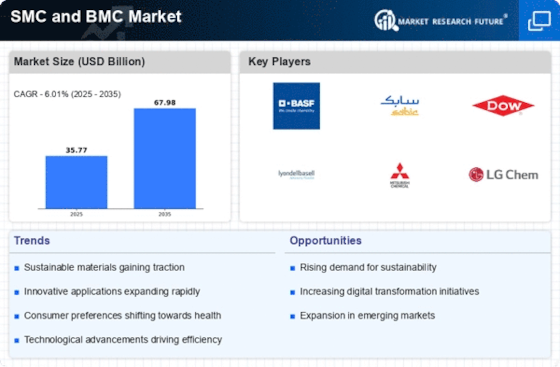

The SMC and BMC Market is experiencing a notable increase in demand for lightweight materials, driven by the automotive and aerospace sectors. These industries are increasingly focused on enhancing fuel efficiency and reducing emissions, which lightweight materials can facilitate. For instance, the use of SMC and BMC composites can lead to weight reductions of up to 30% compared to traditional materials. This trend is further supported by regulatory pressures aimed at lowering carbon footprints, compelling manufacturers to adopt innovative materials. As a result, the SMC and BMC Market is likely to witness substantial growth, with projections indicating a compound annual growth rate of around 6% over the next five years.

Growing Applications in Renewable Energy

The SMC and BMC Market is witnessing a surge in applications within the renewable energy sector. As the world shifts towards sustainable energy solutions, materials that can withstand harsh environmental conditions are in high demand. SMC and BMC composites are increasingly utilized in wind turbine blades and solar panel frames due to their durability and resistance to corrosion. This trend is expected to drive market growth, with estimates suggesting that the renewable energy segment could account for over 15% of the total SMC and BMC Market by 2026. The integration of these materials into renewable energy applications not only enhances performance but also aligns with global sustainability goals.

Increased Investment in Infrastructure Development

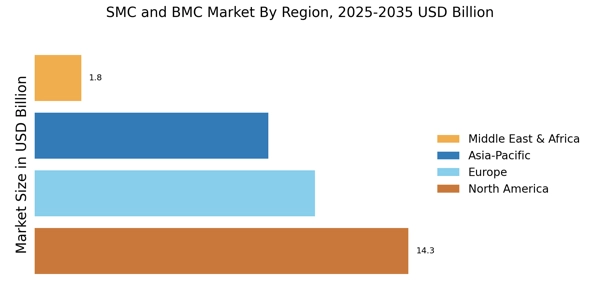

The SMC and BMC Market is benefiting from heightened investment in infrastructure development across various regions. Governments are allocating substantial budgets for the construction and renovation of public infrastructure, including bridges, roads, and buildings. The durability and versatility of SMC and BMC materials make them ideal for these applications, as they can withstand extreme weather conditions and provide long-lasting solutions. This trend is likely to propel the SMC and BMC Market forward, with forecasts indicating a potential increase in demand by 25% over the next five years. The ongoing infrastructure projects are expected to create a robust market environment for SMC and BMC products.

Technological Innovations in Manufacturing Processes

Technological advancements are playing a pivotal role in the SMC and BMC Market, particularly in manufacturing processes. Innovations such as automated production lines and advanced molding techniques are enhancing efficiency and reducing production costs. For example, the introduction of digital twin technology allows manufacturers to simulate and optimize production processes, leading to improved quality and reduced waste. This shift towards automation and smart manufacturing is expected to increase the competitiveness of SMC and BMC products, thereby expanding their market share. The SMC and BMC Market is poised for growth as these technologies become more widely adopted, potentially increasing production capacity by 20% in the coming years.