Increased Focus on Aesthetic Appeal

The Solvent Based Ink Market is significantly impacted by the growing emphasis on aesthetic appeal in product packaging and branding. Companies are increasingly recognizing the importance of visual presentation in attracting consumers. Solvent-based inks, known for their vibrant colors and glossy finishes, are preferred for applications where aesthetics are paramount. This trend is particularly evident in the cosmetics, food, and beverage industries, where packaging design plays a critical role in consumer choice. As brands strive to differentiate themselves in a competitive market, the demand for high-quality solvent-based inks is likely to rise. This focus on aesthetics not only drives sales but also enhances brand loyalty, further propelling the growth of the solvent-based ink market.

Rising Demand in Packaging Industry

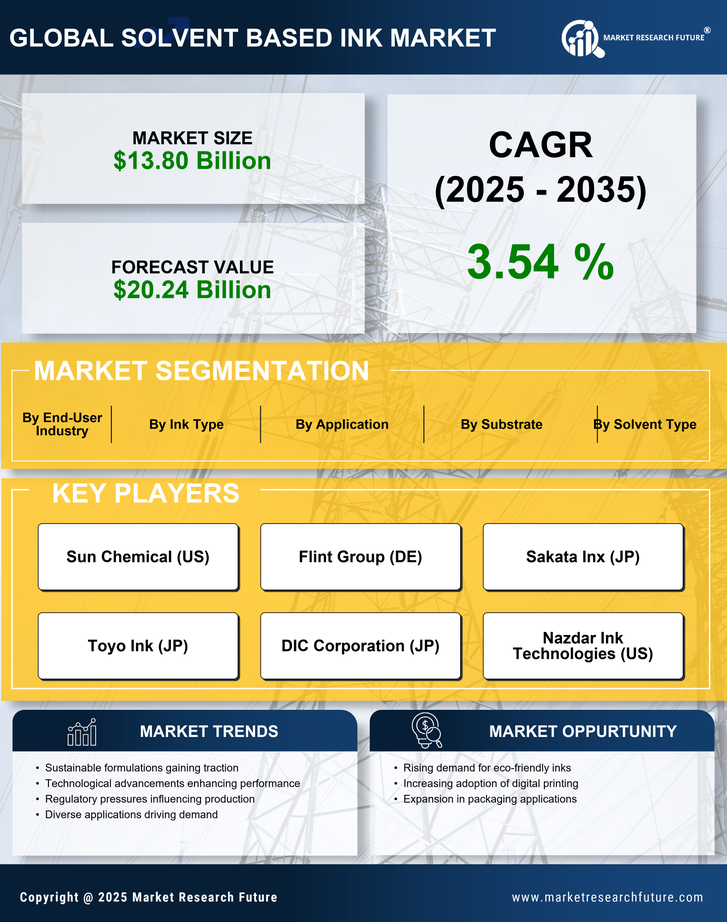

The Solvent Based Ink Market experiences a notable surge in demand driven by the packaging sector. As consumer preferences shift towards visually appealing packaging, manufacturers increasingly rely on solvent-based inks for their vibrant colors and durability. The packaging industry, which is projected to grow at a compound annual growth rate of approximately 4.5% over the next few years, significantly influences the solvent-based ink market. This growth is attributed to the rising e-commerce sector, where packaging plays a crucial role in product presentation. Furthermore, solvent-based inks are favored for their ability to adhere to various substrates, enhancing the overall quality of packaging. As a result, the solvent-based ink market is likely to witness sustained growth, propelled by the packaging industry's evolving needs.

Growth in Digital Printing Applications

The rise of digital printing technologies is reshaping the Solvent Based Ink Market. Digital printing offers flexibility and efficiency, allowing for shorter production runs and customization. As businesses seek to enhance their branding and marketing efforts, the demand for high-quality prints has surged. Solvent-based inks are particularly well-suited for digital printing applications, providing excellent color reproduction and durability. The digital printing market is anticipated to grow at a robust pace, with solvent-based inks playing a crucial role in meeting the diverse needs of various sectors, including signage, textiles, and promotional materials. This trend suggests a promising future for the solvent-based ink market as it adapts to the evolving landscape of printing technologies.

Technological Innovations in Ink Production

Technological advancements within the Solvent Based Ink Market are pivotal in shaping its future. Innovations in ink formulation and production processes have led to the development of high-performance inks that offer improved adhesion, faster drying times, and enhanced color stability. For instance, the introduction of advanced pigment technologies has enabled manufacturers to produce inks with superior lightfastness and resistance to environmental factors. Additionally, automation in production processes has streamlined operations, reducing costs and increasing efficiency. As the industry continues to embrace these technological innovations, it is expected that the solvent-based ink market will expand, catering to the growing demands of various applications, including textiles, labels, and graphics.

Regulatory Compliance and Environmental Standards

The Solvent Based Ink Market is increasingly influenced by stringent regulatory compliance and environmental standards. Governments and regulatory bodies are implementing measures to reduce volatile organic compounds (VOCs) in inks, prompting manufacturers to innovate and adapt their formulations. This shift towards eco-friendly solutions is likely to drive the development of low-VOC and water-based alternatives, which may impact the traditional solvent-based ink market. However, solvent-based inks still hold a significant share due to their performance characteristics. The market is expected to evolve as manufacturers balance compliance with performance, potentially leading to a hybrid approach that incorporates both solvent-based and eco-friendly inks.