Technological Innovations

Technological advancements play a pivotal role in shaping the Stationary Emission Control Catalyst Market. Innovations in catalyst formulations and designs are enhancing the efficiency and effectiveness of emission control systems. For example, the development of new materials, such as advanced zeolites and metal-organic frameworks, is improving catalyst performance and longevity. Furthermore, the integration of artificial intelligence and machine learning in monitoring and optimizing catalyst operations is becoming increasingly prevalent. These innovations not only help in achieving lower emissions but also reduce operational costs for industries. As a result, the Stationary Emission Control Catalyst Market is likely to witness significant growth driven by these technological breakthroughs.

Increasing Regulatory Pressure

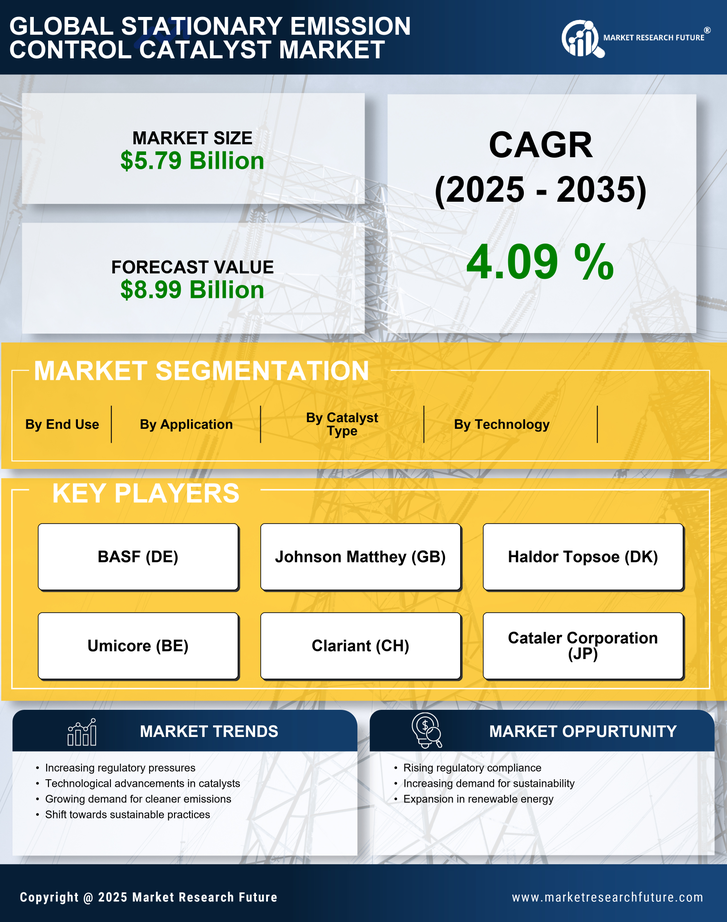

The Stationary Emission Control Catalyst Market is experiencing heightened regulatory pressure aimed at reducing emissions from industrial sources. Governments are implementing stringent regulations to limit pollutants such as nitrogen oxides (NOx) and sulfur oxides (SOx). For instance, the U.S. Environmental Protection Agency has set ambitious targets for emission reductions, which has led to increased demand for advanced catalytic solutions. This regulatory landscape compels industries to adopt more efficient emission control technologies, thereby driving growth in the catalyst market. The market is projected to expand as companies invest in compliance technologies to meet these evolving standards, indicating a robust future for the Stationary Emission Control Catalyst Market.

Rising Environmental Awareness

There is a growing awareness regarding environmental issues, which is significantly influencing the Stationary Emission Control Catalyst Market. As public concern about air quality and climate change intensifies, industries are under pressure to adopt cleaner technologies. This shift is prompting manufacturers to invest in emission control solutions that align with sustainability goals. According to recent studies, the demand for catalysts that can effectively reduce harmful emissions is expected to rise by over 20% in the next five years. This trend indicates a strong market potential for the Stationary Emission Control Catalyst Market, as companies strive to enhance their environmental performance and meet consumer expectations.

Investment in Clean Technologies

Investment in clean technologies is becoming a crucial driver for the Stationary Emission Control Catalyst Market. Governments and private sectors are channeling funds into research and development of innovative emission control solutions. This financial commitment is aimed at fostering advancements in catalyst technologies that can significantly reduce emissions from stationary sources. For instance, initiatives promoting the use of renewable energy sources and energy-efficient processes are likely to boost the demand for effective catalysts. As industries transition towards cleaner operations, the Stationary Emission Control Catalyst Market is expected to benefit from increased investments, leading to enhanced product offerings and market growth.

Industrial Growth and Urbanization

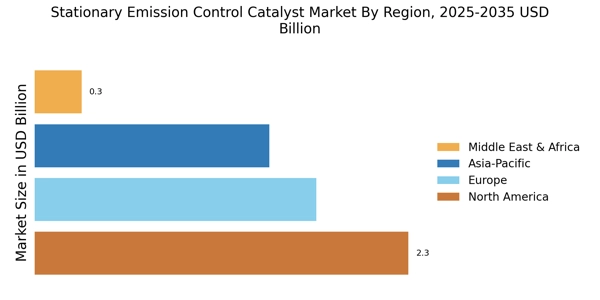

The rapid pace of industrial growth and urbanization is a significant driver for the Stationary Emission Control Catalyst Market. As economies develop, there is an increase in energy consumption and industrial activities, leading to higher emissions. Urban areas, in particular, are facing challenges related to air quality due to increased vehicular and industrial emissions. This scenario necessitates the implementation of effective emission control technologies, including catalysts. The market is expected to grow as industries seek to mitigate their environmental impact and comply with regulatory requirements. Consequently, the Stationary Emission Control Catalyst Market is poised for expansion in response to these urbanization trends.