Expansion in Oil and Gas Sector

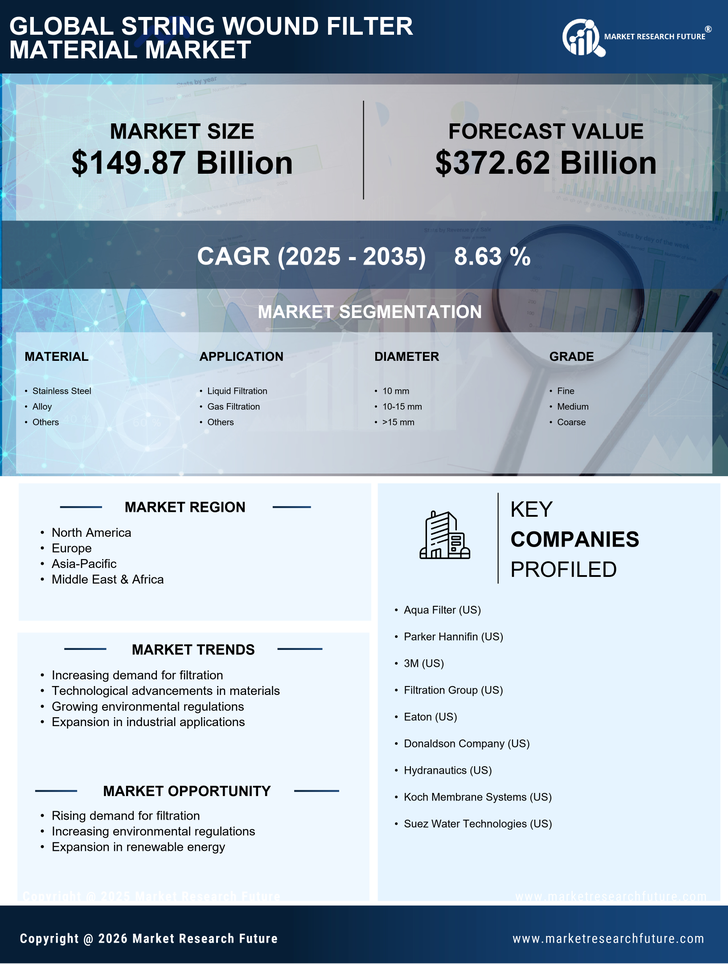

The String Wound Filter Material Market is significantly influenced by the expansion of the oil and gas sector. String wound filters are essential in the filtration processes of drilling fluids and produced water treatment, ensuring the removal of contaminants and particulates. As the oil and gas industry continues to evolve, with investments projected to exceed USD 3 trillion by 2025, the demand for efficient filtration solutions is likely to rise. String wound filters offer a cost-effective and reliable option for maintaining the integrity of drilling operations and enhancing the quality of produced water. This growth in the oil and gas sector is expected to drive the String Wound Filter Material Market, creating new opportunities for manufacturers and suppliers.

Rising Demand in Water Treatment

The String Wound Filter Material Market is experiencing a notable increase in demand due to the growing need for effective water treatment solutions. As water quality regulations become more stringent, industries are compelled to adopt advanced filtration technologies. String wound filters, known for their high dirt-holding capacity and efficiency, are increasingly utilized in municipal and industrial water treatment applications. The market for water treatment is projected to reach USD 1 trillion by 2025, indicating a substantial opportunity for string wound filter materials. This trend is further fueled by the rising awareness of water scarcity and the necessity for sustainable water management practices, positioning the String Wound Filter Material Market favorably for growth.

Growing Environmental Regulations

The String Wound Filter Material Market is significantly impacted by the increasing environmental regulations aimed at reducing pollution and promoting sustainability. Governments worldwide are implementing stricter guidelines for waste management and water quality, necessitating the use of effective filtration solutions. String wound filters are recognized for their ability to efficiently remove contaminants from wastewater and industrial effluents, making them essential in compliance with these regulations. As industries strive to meet environmental standards, the demand for string wound filter materials is likely to grow. The market is expected to benefit from this regulatory landscape, as companies invest in filtration technologies to ensure compliance and enhance their sustainability efforts.

Increased Industrial Filtration Needs

The String Wound Filter Material Market is poised for growth due to the increasing filtration needs across various industrial sectors. Industries such as pharmaceuticals, food and beverage, and chemicals require high-quality filtration solutions to ensure product purity and compliance with safety standards. The String Wound Filter Material Market is anticipated to reach USD 40 billion by 2025, with string wound filters playing a crucial role in meeting these demands. Their ability to effectively remove particulates and contaminants makes them a preferred choice in critical applications. As industries continue to prioritize quality and safety, the String Wound Filter Material Market is likely to benefit from this trend, leading to enhanced market opportunities.

Technological Innovations in Filtration

The String Wound Filter Material Market is being propelled by ongoing technological innovations in filtration processes. Advancements in materials science and manufacturing techniques have led to the development of more efficient and durable string wound filters. These innovations enhance the performance of filters, allowing for better contaminant removal and longer service life. As industries seek to optimize their filtration systems, the demand for technologically advanced string wound filters is expected to rise. The integration of smart technologies, such as IoT-enabled monitoring systems, could further enhance the functionality of these filters. This trend indicates a promising future for the String Wound Filter Material Market, as manufacturers adapt to the evolving needs of various sectors.