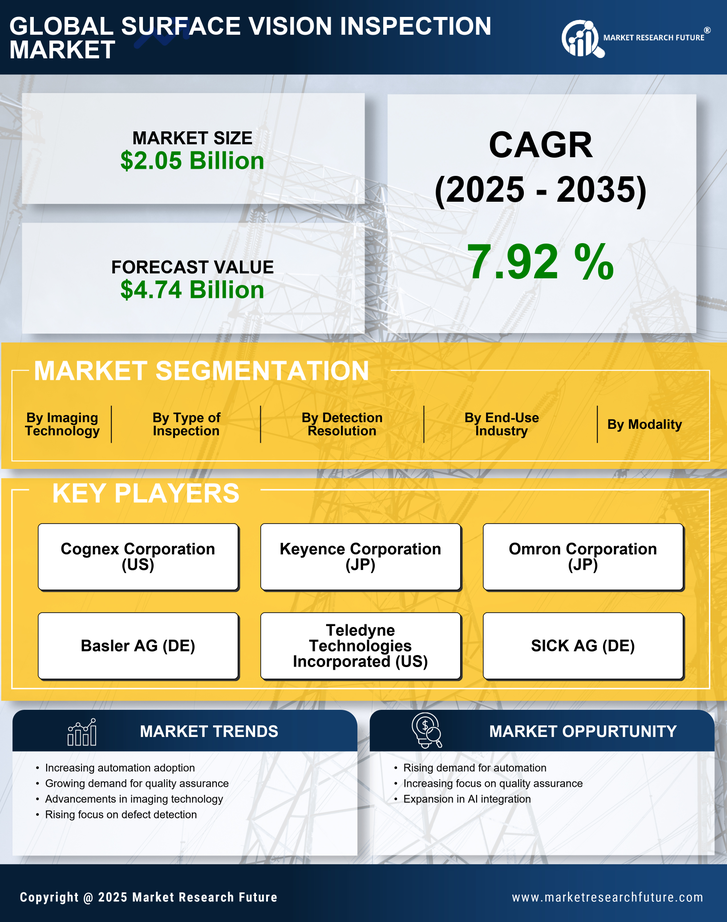

Increased Focus on Automation

The Surface Vision Inspection Market is significantly influenced by the increased focus on automation across various sectors. As companies strive to enhance productivity and reduce labor costs, automated inspection systems are becoming indispensable. The integration of robotics and artificial intelligence into inspection processes allows for faster and more accurate evaluations of product quality. Data suggests that the automation market is projected to grow at a rate of 8% annually, which directly correlates with the rising adoption of surface vision inspection technologies. This trend indicates that businesses are recognizing the value of automated solutions in maintaining high standards of quality while optimizing resource allocation. Consequently, the Surface Vision Inspection Market is likely to thrive as automation continues to reshape operational paradigms.

Rising Environmental Concerns

Rising environmental concerns are increasingly shaping the Surface Vision Inspection Market. As industries face pressure to adopt sustainable practices, the demand for inspection systems that minimize waste and enhance resource efficiency is growing. Companies are now more aware of their environmental impact and are seeking technologies that align with sustainability goals. The market for eco-friendly inspection solutions is expected to expand, driven by regulatory pressures and consumer preferences for sustainable products. This shift towards environmentally conscious practices suggests that the Surface Vision Inspection Market will evolve to incorporate solutions that not only ensure quality but also promote sustainability. As a result, organizations are likely to invest in inspection technologies that support their environmental initiatives.

Growing Demand for Quality Assurance

Quality assurance remains a pivotal driver in the Surface Vision Inspection Market. As industries strive to meet stringent quality standards, the need for reliable inspection systems has intensified. The automotive and aerospace sectors, in particular, are witnessing a heightened focus on quality control, leading to increased investments in surface vision inspection technologies. According to recent data, the market for quality assurance solutions is projected to grow significantly, with a compound annual growth rate of over 10% in the coming years. This growth is indicative of the broader trend towards ensuring product reliability and safety, which is essential for maintaining consumer trust and compliance with regulatory requirements. Consequently, the Surface Vision Inspection Market is poised to benefit from this growing emphasis on quality assurance.

Expansion of Manufacturing Capabilities

The expansion of manufacturing capabilities is a crucial driver for the Surface Vision Inspection Market. As manufacturers scale operations to meet rising consumer demands, the need for efficient inspection systems becomes paramount. Industries such as electronics and pharmaceuticals are increasingly adopting surface vision inspection technologies to streamline production processes and enhance operational efficiency. Recent statistics indicate that the manufacturing sector is expected to grow by approximately 5% annually, further fueling the demand for advanced inspection solutions. This growth trajectory suggests that manufacturers are prioritizing investments in surface vision inspection systems to ensure product integrity and minimize defects. Thus, the Surface Vision Inspection Market is likely to see sustained growth as manufacturers seek to optimize their production lines.

Technological Advancements in Imaging Systems

The Surface Vision Inspection Market is experiencing a surge in technological advancements, particularly in imaging systems. Enhanced camera resolutions and sophisticated algorithms are enabling more precise defect detection and analysis. For instance, the integration of high-definition cameras and advanced image processing techniques has improved the accuracy of inspections across various sectors, including manufacturing and electronics. This trend is likely to drive market growth as companies seek to adopt cutting-edge technologies to enhance product quality and reduce waste. Furthermore, the increasing demand for real-time monitoring solutions is pushing manufacturers to innovate, thereby expanding the Surface Vision Inspection Market. As a result, organizations are investing in state-of-the-art imaging systems to maintain competitive advantages.