Expanding Use in Packaging

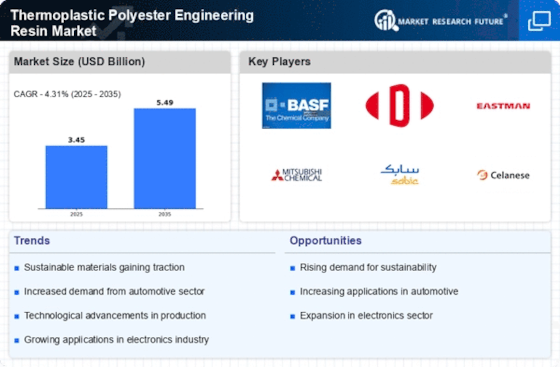

The Thermoplastic Polyester Engineering Resin Market is witnessing an expansion in the packaging sector, driven by the increasing demand for sustainable and recyclable materials. Thermoplastic polyester resins are favored for their excellent barrier properties, which help in preserving the freshness and quality of packaged goods. The packaging industry is projected to grow at a rate of approximately 4% annually, with a significant shift towards eco-friendly solutions. This shift is likely to enhance the adoption of thermoplastic polyester resins, as they can be recycled and reused, aligning with the sustainability goals of many companies. As consumer preferences evolve, the demand for innovative packaging solutions utilizing these resins is expected to rise.

Rising Demand in Electronics

The Thermoplastic Polyester Engineering Resin Market is experiencing a notable increase in demand from the electronics sector. As electronic devices become more compact and lightweight, manufacturers are seeking materials that offer superior performance and durability. Thermoplastic polyester resins provide excellent thermal stability and electrical insulation, making them ideal for applications in connectors, housings, and circuit boards. The market for electronic components is projected to grow significantly, with estimates suggesting a compound annual growth rate of over 5% in the coming years. This trend indicates a robust opportunity for thermoplastic polyester resins, as they align with the industry's need for high-performance materials that can withstand the rigors of modern electronics.

Increased Focus on Sustainability

The Thermoplastic Polyester Engineering Resin Market is increasingly shaped by a heightened focus on sustainability. As environmental concerns gain prominence, manufacturers are under pressure to adopt eco-friendly materials and practices. Thermoplastic polyester resins, known for their recyclability and lower environmental impact, are becoming a preferred choice for many industries. The market for sustainable materials is projected to grow at a rate of around 5% annually, reflecting a shift in consumer preferences towards greener alternatives. This trend suggests that thermoplastic polyester resins will see increased adoption across various sectors, as companies strive to align their products with sustainability goals and reduce their carbon footprint.

Growth in Automotive Lightweighting

The Thermoplastic Polyester Engineering Resin Market is significantly influenced by the automotive sector's ongoing trend towards lightweighting. As manufacturers strive to improve fuel efficiency and reduce emissions, the use of lightweight materials has become paramount. Thermoplastic polyester resins offer a compelling solution due to their strength-to-weight ratio and ability to withstand high temperatures. The automotive industry is anticipated to grow at a rate of around 3% annually, with a substantial portion of this growth attributed to the increasing adoption of advanced materials. This trend suggests that thermoplastic polyester resins will play a crucial role in the development of next-generation vehicles, particularly in components such as interior parts and structural elements.

Innovations in Manufacturing Processes

The Thermoplastic Polyester Engineering Resin Market is benefiting from innovations in manufacturing processes, which enhance the efficiency and quality of resin production. Advances such as 3D printing and injection molding are enabling manufacturers to create complex geometries and reduce waste. These innovations are likely to drive down production costs and improve the overall performance of thermoplastic polyester resins. The market for advanced manufacturing technologies is expected to grow at a compound annual growth rate of approximately 6% over the next few years. This growth indicates a favorable environment for the thermoplastic polyester engineering resin market, as manufacturers seek to leverage these technologies to meet the increasing demand for high-performance materials.