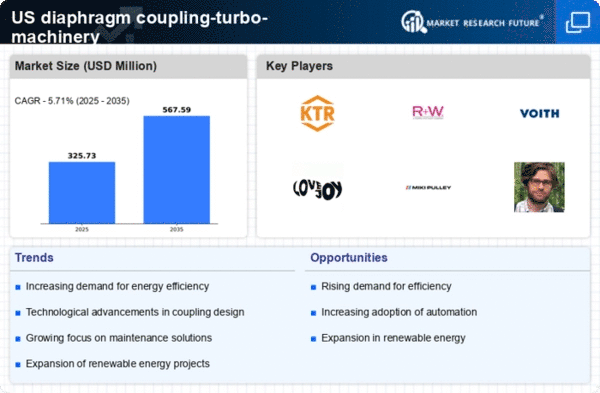

Increased Industrial Automation

The diaphragm coupling-turbo-machinery market is benefiting from the ongoing trend of increased industrial automation. As industries adopt advanced automation technologies, the need for reliable and efficient machinery becomes paramount. Diaphragm couplings are essential components in automated systems, providing flexibility and reducing maintenance requirements. The automation market in the US is projected to reach $300 billion by 2025, which suggests a substantial opportunity for diaphragm coupling manufacturers. This growth in automation not only enhances productivity but also drives the demand for high-performance coupling solutions, thereby positively impacting the diaphragm coupling-turbo-machinery market.

Growth in Renewable Energy Projects

The diaphragm coupling-turbo-machinery market is poised for growth due to the expansion of renewable energy projects across the United States. As the country transitions towards cleaner energy sources, there is a rising need for reliable machinery that can support wind, solar, and hydroelectric power generation. Diaphragm couplings play a crucial role in ensuring the smooth operation of turbines and generators in these applications. The renewable energy sector is expected to witness investments exceeding $100 billion by 2026, which could significantly boost the demand for diaphragm coupling solutions. This trend indicates a promising future for the diaphragm coupling-turbo-machinery market as it aligns with the broader shift towards sustainable energy.

Regulatory Compliance and Safety Standards

The diaphragm coupling-turbo-machinery market is influenced by stringent regulatory compliance and safety standards across various industries. As companies strive to meet these regulations, there is an increasing emphasis on using high-quality components that ensure operational safety and reliability. Diaphragm couplings are recognized for their ability to minimize vibration and misalignment, which are critical factors in maintaining safety standards. The market is likely to see a rise in demand as industries prioritize compliance with regulations, potentially leading to a market growth rate of around 5% annually. This focus on safety and compliance is expected to drive the diaphragm coupling-turbo-machinery market forward.

Technological Innovations in Coupling Design

The diaphragm coupling-turbo-machinery market is witnessing a wave of technological innovations in coupling design. Manufacturers are investing in research and development to create advanced coupling solutions that offer improved performance and durability. Innovations such as lightweight materials and enhanced flexibility are becoming increasingly prevalent, catering to the evolving needs of various industries. The market for advanced coupling technologies is anticipated to grow significantly, with estimates suggesting a potential increase of 7% in the next few years. This trend indicates that the diaphragm coupling-turbo-machinery market is likely to thrive as it adapts to the demands of modern machinery and applications.

Rising Demand for Efficient Power Transmission

The diaphragm coupling-turbo-machinery market is experiencing a notable increase in demand for efficient power transmission solutions. Industries such as oil and gas, power generation, and manufacturing are seeking to enhance operational efficiency and reduce energy losses. This trend is driven by the need for reliable and high-performance machinery that can withstand harsh operating conditions. According to recent data, the market for diaphragm couplings is projected to grow at a CAGR of approximately 6% over the next five years, reflecting the increasing adoption of advanced coupling technologies. As companies strive to optimize their processes, the diaphragm coupling-turbo-machinery market is likely to benefit from this heightened focus on efficiency.

.png)