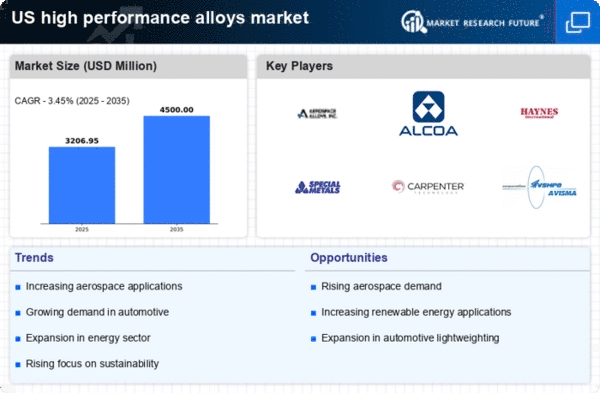

The high performance-alloys market is characterized by a dynamic competitive landscape, driven by increasing demand across aerospace, automotive, and energy sectors. Key players such as Aerospace Alloys (US), Alcoa Corporation (US), and

Haynes International (US) are strategically positioned to leverage innovation and technological advancements. Aerospace Alloys (US) focuses on developing specialized alloys for aerospace applications, while Alcoa Corporation (US) emphasizes sustainability through its low-carbon aluminum production. Haynes International (US) is known for its high-performance nickel-based alloys, catering to the needs of the aerospace and chemical processing industries. Collectively, these strategies foster a competitive environment that prioritizes innovation and sustainability, shaping market dynamics.In terms of business tactics, companies are increasingly localizing manufacturing to enhance supply chain resilience and reduce lead times. The market structure appears moderately fragmented, with several players vying for market share. However, the influence of major companies is significant, as they set industry standards and drive technological advancements. This competitive structure encourages smaller firms to innovate and differentiate their offerings, contributing to a vibrant market ecosystem.

In October Alcoa Corporation (US) announced a partnership with a leading renewable energy firm to develop low-carbon aluminum solutions. This strategic move underscores Alcoa's commitment to sustainability and positions the company to meet the growing demand for environmentally friendly materials. By aligning with renewable energy initiatives, Alcoa aims to enhance its market presence while addressing the increasing regulatory pressures for sustainable practices.

In September Haynes International (US) launched a new line of high-performance alloys specifically designed for the aerospace sector. This introduction reflects the company's focus on innovation and its ability to respond to evolving customer needs. By expanding its product portfolio, Haynes International strengthens its competitive position and enhances its appeal to aerospace manufacturers seeking advanced materials.

In August Aerospace Alloys (US) expanded its manufacturing capabilities by investing in advanced production technologies. This investment is likely to improve efficiency and product quality, enabling the company to better serve its clients in the aerospace industry. Such strategic enhancements are crucial for maintaining competitiveness in a market that increasingly values precision and reliability.

As of November current trends in the high performance-alloys market include a strong emphasis on digitalization, sustainability, and the integration of artificial intelligence (AI) in manufacturing processes. Strategic alliances are becoming more prevalent, as companies seek to pool resources and expertise to drive innovation. The competitive landscape is shifting from traditional price-based competition to a focus on technological advancements and supply chain reliability. This evolution suggests that companies that prioritize innovation and sustainability will likely emerge as leaders in the high performance-alloys market.