US Industrial Films Market Overview:

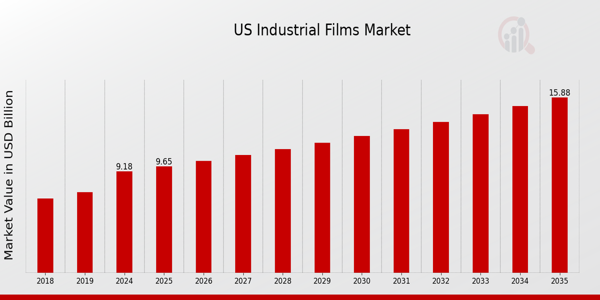

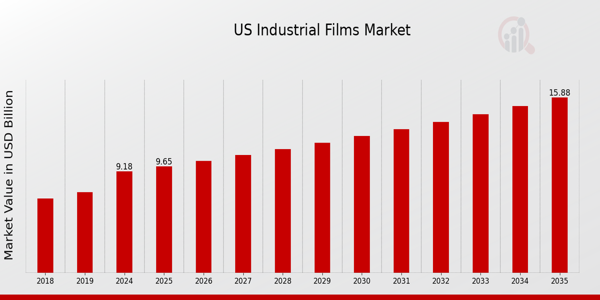

The US Industrial Films Market Size was estimated at 8.73 (USD Billion) in 2023. The US Industrial Films Market is expected to grow from 9.18(USD Billion) in 2024 to 15.88 (USD Billion) by 2035. The US Industrial Films Market CAGR (growth rate) is expected to be around 5.106% during the forecast period (2025 - 2035).

Key US Industrial Films Market Trends Highlighted

The US Industrial Films Market is witnessing a significant shift driven by the increasing demand for lightweight materials in various industries such as automotive, construction, and packaging. This trend is fueled by the need for improved fuel efficiency and sustainability, as lightweight films contribute to lower emissions and greater energy savings. Additionally, there has been a growing inclination towards renewable and recyclable materials, as industries strive to meet stricter environmental regulations and consumer preferences for eco-friendly products.

As a result, manufacturers are investing in research and development to innovate bio-based and biodegradable industrial film alternatives.There are ample opportunities to be explored in the market, particularly in the area of advanced manufacturing technologies like 3D printing and additive manufacturing. These technologies allow for more personalized and efficient production processes, enabling companies to cater to specific customer needs while reducing material waste. Moreover, the rise of e-commerce is stimulating demand for durable packaging solutions, which industrial films can provide, particularly in protecting products during transit.

In recent times, the US Industrial Films Market has seen an increase in collaboration between film producers and end-users to create customized solutions that meet specific industry demands.This collaboration promotes a better understanding of market needs and facilitates the development of tailored products that enhance performance while reducing costs. Furthermore, the increased investments by US companies to modernize their manufacturing facilities contribute to improved production efficiency and greater competitiveness in the market. As stakeholders adapt to these evolving trends, the US Industrial Films Market is likely to continue growing, driven by innovation and demand for sustainable solutions.

Source: Primary Research, Secondary Research, Market Research Future Database and Analyst Review

US Industrial Films Market Drivers

Growing Demand for Sustainable Packaging Solutions

The US Industrial Films Market is experiencing significant growth due to the increasing demand for sustainable packaging solutions. With consumers and businesses increasingly prioritizing environmental responsibility, companies are focusing on developing biodegradable and recyclable films. The US Environmental Protection Agency (EPA) reported that plastic waste has increased by 22% over the last decade, leading to a high demand for alternative packaging materials that reduce environmental impact.This trend is further supported by organizations such as the Sustainable Packaging Coalition, which promotes the adoption of sustainable practices in packaging.

The commitment of major companies like Coca-Cola and Unilever to switch to eco-friendly packaging solutions reinforces this shift, ultimately driving the growth of the US Industrial Films Market.

Technological Advancements in Film Production

Technological advancements in film production processes are enhancing the capabilities and applications of industrial films, contributing to market growth. Innovations in polymer technology and film extrusion processes have improved film strength, barrier properties, and durability. According to the National Association of Manufacturers, over 80% of US manufacturers are investing in new technologies to enhance productivity and efficiency.

Companies such as Berry Global and Amcor are leading this trend by incorporating advanced manufacturing techniques, which not only improve product quality but also expand the range of applications across various industries, including automotive, healthcare, and construction.As these innovations continue to evolve, they will play a crucial role in the expansion of the US Industrial Films Market.

Increasing Industrial Applications of Films

The increasing adoption of industrial films in various sectors such as automotive, construction, and healthcare is driving the growth of the US Industrial Films Market Industry. For instance, the automotive sector is utilizing films for interior and exterior applications, contributing to lighter vehicle weights and improved fuel efficiency. The Bureau of Economic Analysis reported that the manufacturing sector in the US is expected to grow by 3.5% annually, driven by advancements in technology and emphasis on lightweight materials.Firms like DuPont and 3M are investing heavily in developing specialized films tailored for industrial use.

This expansion into new industrial applications is integral to the future prospects of the US Industrial Films Market.

US Industrial Films Market Segment Insights:

Industrial Films Market Material Type Insights

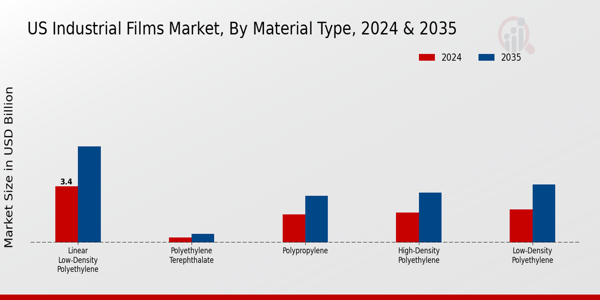

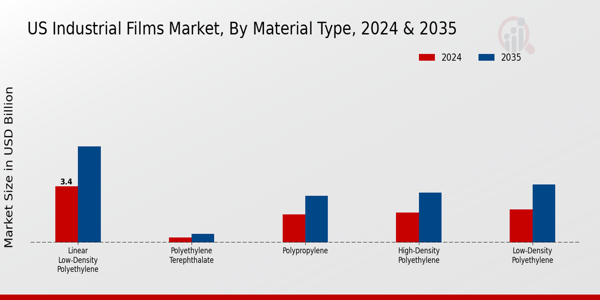

The US Industrial Films Market is a vital component of the overall manufacturing and packaging industry, primarily segmented by material type, which includes a variety of polymers. Each material type plays a critical role in determining the applications and performance characteristics of the films produced. Linear Low-Density Polyethylene (LLDPE) is often preferred for its flexibility and impact resistance, making it suitable for applications where stretch and durability are essential. Low-Density Polyethylene (LDPE) remains popular due to its ease of processing and low cost, allowing it to be used in various packaging and agricultural films.

High-Density Polyethylene (HDPE) is recognized for its high tensile strength and is heavily favored in the production of more robust industrial applications, including containers and heavy-duty bags.Polypropylene (PP) exhibits excellent chemical resistance and is frequently utilized in applications that require a high degree of transparency and clarity. Its versatility enhances its importance across various industries, especially in the production of textiles and automotive components. Polyethylene Terephthalate (PET) stands out for its excellent barrier properties, often being used for packaging food and beverages, contributing significantly to the sustainability efforts with its recycling potential.

Poly Vinyl Chloride (PVC) is notable for its durability and wide range of application in construction and electrical cable insulation, showcasing its significance in various sectors requiring strength and resistance. Polyamide, known for its toughness and heat resistance, is essential in the manufacture of films used for technical applications where mechanical strength is critical.The diversity in material types reflects the wide-ranging applications of industrial films, from agriculture to construction, manufacturing, and beyond. Each material type contributes uniquely to the functionality, cost-effectiveness, and sustainability of products in the US market.

As industries continue to evolve with technological advancements, the demand for specific performance characteristics drives the growth of these material segments within the US Industrial Films Market. Understanding these dynamics helps identify opportunities and challenges faced by manufacturers aiming for innovative solutions while adhering to environmental standards and consumer preferences.

Source: Primary Research, Secondary Research, Market Research Future Database and Analyst Review

Industrial Films Market End-Use Insights

The US Industrial Films Market demonstrates diverse applications across various end-use sectors, highlighting its critical role in the industrial landscape. Within the Transportation sector, industrial films are crucial for enhancing safety and performance, particularly in automotive and aerospace industries. Similarly, the Construction industry leverages these films for insulation and moisture control, ensuring structural integrity and energy efficiency.

In Industrial Packaging, these films are essential for protecting goods from environmental factors during storage and transport, contributing significantly to the logistics sector's efficiency.The Agriculture segment finds value in films used for crop protection and greenhouse applications, which aid in achieving higher yields and sustainability. In the Medical field, films serve vital purposes in packaging and sterilization processes, ensuring product safety and compliance with health regulations. Other applications encompass various niche uses that further enrich the overall market.

These segments collectively reinforce the significance of the US Industrial Films Market as they adapt to changing demands and technological advancements, driven by the need for performance, safety, and sustainability across industries.As a result, understanding the intricate dynamics of these end-use applications is essential for stakeholders aiming to capitalize on trends and growth opportunities in this ever-evolving market.

US Industrial Films Market Key Players and Competitive Insights:

The competitive landscape of the US Industrial Films Market is characterized by dynamic growth driven by innovation, technological advancements, and changing consumer demands. This market encompasses a wide range of products used in various applications, including packaging, automotive, electronics, and insulation. The competition is intense, with multiple players vying for market share, each leveraging their unique strengths in manufacturing capabilities, product quality, and customer service.

Factors such as sustainability initiatives, advancements in polymers, and the need for lightweight materials continue to shape the competitive dynamics, prompting firms to invest in research and development to create specialized films designed for niche applications. The ongoing trend towards environmentally friendly materials also plays a critical role in how companies position themselves within this market. Celanese has established a robust presence in the US Industrial Films Market with a diverse portfolio of specialty polymers and engineered materials.

The company distinguishes itself through its commitment to innovation and high-quality manufacturing processes, which enable the production of superior-grade films suitable for demanding applications. Celanese's strength lies in its extensive technical expertise, allowing it to deliver customized solutions that meet stringent industry requirements. The company's strategic partnerships and collaborations have further enhanced its operational capabilities, providing it with a competitive edge in reaching various end markets effectively.

By leveraging its research and development efforts, Celanese continually adapts to the evolving market conditions and broadens its product offerings, thereby solidifying its leadership position in the industrial films sector.Polyonics has carved out a significant niche in the US Industrial Films Market primarily through its specialized high-performance films and labeling solutions. The company offers a range of products designed for thermal transfer printing, exposing its deep understanding of the industrial needs across various sectors.

Polyonics' strengths lie in its ability to provide tailored products that excel in high-temperature and harsh environment applications, making it a go-to choice for industries such as aerospace and manufacturing. Through strategic mergers and acquisitions, Polyonics has expanded its technological capabilities and market reach, enabling it to increase its production efficiencies and enhance its product line. Continuous investments in research and development allow Polyonics to keep pace with evolving market trends, ensuring that it delivers innovative solutions to its clients. The company's focus on quality and customer satisfaction further solidifies its reputation and competitiveness in the US Industrial Films Market.

Key Companies in the US Industrial Films Market Include:

US Industrial Films Market Industry Developments

The US Industrial Films Market has seen notable activity recently with significant developments among key players. In September 2023, Celanese announced a new production facility aimed at increasing its capacity for high-performance films to meet growing demand in various sectors. Polyonics has been expanding its product portfolio with innovative solutions tailored for the electronics industry, addressing the increasing requirements for durable and high-temperature resistant films. Additionally, in August 2023, ExxonMobil disclosed plans to advance its sustainable film technology, focusing on reducing environmental impact while enhancing performance.

A major acquisition occurred in June 2023, when 3M acquired a technology startup specializing in advanced polymer films, which will improve their competitive edge in the market. Growth in the US Industrial Films Market has been supported by increasing applications in automotive, aerospace, and electronics, reportedly valued at approximately USD 4 billion in 2022, with expectations for continued expansion. The demand for sustainable and high-performance materials is rapidly transforming the industry, with companies like DuPont and BASF leading with innovations that cater to eco-conscious consumer bases.

Overall, these developments showcase the dynamic nature of the US Industrial Films Market and its potential for future growth.

US Industrial Films Market Segmentation Insights

Industrial Films Market Material Type Outlook

- Linear Low-Density Polyethylene (LLDPE)

- Low-Density Polyethylene (LDPE)

- High-Density Polyethylene (HDPE)

- Polyethylene Terephthalate (PET)

- Poly Vinyl Chloride (PVC)

Industrial Films Market End-Use Outlook

| Report Attribute/Metric Source: |

Details |

| MARKET SIZE 2018 |

8.73(USD Billion) |

| MARKET SIZE 2024 |

9.18(USD Billion) |

| MARKET SIZE 2035 |

15.88(USD Billion) |

| COMPOUND ANNUAL GROWTH RATE (CAGR) |

5.106% (2025 - 2035) |

| REPORT COVERAGE |

Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| BASE YEAR |

2024 |

| MARKET FORECAST PERIOD |

2025 - 2035 |

| HISTORICAL DATA |

2019 - 2024 |

| MARKET FORECAST UNITS |

USD Billion |

| KEY COMPANIES PROFILED |

Celanese, Polyonics, ExxonMobil, Silicone Engineering, BASF, Hepco, Mitsubishi Chemical, SABIC, Toray Industries, Eastman Chemical, Covestro, DuPont, LG Chem, 3M, Honeywell |

| SEGMENTS COVERED |

Material Type, End-Use |

| KEY MARKET OPPORTUNITIES |

Sustainable film innovations, Lightweight materials demand, Automation in manufacturing processes, Growth in packaging applications, Increased industrial safety regulations |

| KEY MARKET DYNAMICS |

growing demand for sustainable materials, increasing automation in manufacturing, rising investment in packaging technologies, advancements in polymer production, fluctuating raw material prices |

| COUNTRIES COVERED |

US |

Frequently Asked Questions (FAQ):

The US Industrial Films Market is expected to be valued at 9.18 billion USD in 2024.

By 2035, the market is expected to reach a value of 15.88 billion USD.

The market is expected to experience a CAGR of 5.106 percent during the forecast period from 2025 to 2035.

Linear Low-Density Polyethylene (LLDPE) is the largest segment, valued at 3.4 billion USD in 2024.

The market value for Low-Density Polyethylene (LDPE) is projected to be 3.5 billion USD by 2035.

Key players include Celanese, Polyonics, ExxonMobil, and BASF among others.

The market for Polypropylene (PP) is expected to grow from 1.7 billion USD in 2024 to 2.8 billion USD by 2035.

The market for High-Density Polyethylene (HDPE) is anticipated to reach 3.0 billion USD by 2035.

Key growth drivers include rising demand for sustainable packaging and innovation in film technology.

Polyethylene Terephthalate (PET) is projected to have a market value of 0.5 billion USD in 2035.