E-commerce Growth

The rapid expansion of e-commerce in the US is a pivotal driver for the industrial packaging market. As online shopping continues to gain traction, businesses require robust packaging solutions to ensure product safety during transit. In 2025, e-commerce sales are projected to reach approximately $1 trillion, necessitating innovative packaging designs that cater to diverse product types. This surge in demand compels manufacturers to develop packaging that is not only durable but also cost-effective. The industrial packaging market must adapt to these evolving needs, focusing on materials that enhance protection while minimizing waste. Furthermore, the rise of direct-to-consumer models amplifies the need for efficient packaging solutions, as companies strive to optimize logistics and reduce shipping costs. Consequently, the industrial packaging market is likely to experience significant growth driven by the e-commerce sector.

Regulatory Compliance

Regulatory compliance remains a critical driver for the industrial packaging market, particularly in sectors such as food and pharmaceuticals. The US government enforces stringent regulations to ensure product safety and environmental protection. For instance, the Food and Drug Administration (FDA) mandates specific packaging standards for food products, which influences packaging design and materials. In 2025, the industrial packaging market is expected to see a rise in demand for compliant packaging solutions, as companies prioritize adherence to these regulations. This trend may lead to increased investments in research and development to create packaging that meets regulatory requirements while maintaining functionality. Additionally, the emphasis on sustainability in regulations could drive innovation in eco-friendly packaging materials, further shaping the industrial packaging market landscape.

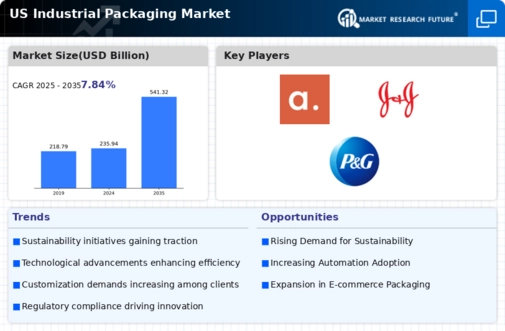

Sustainability Pressure

Sustainability pressure is increasingly shaping the industrial packaging market as consumers and businesses alike prioritize eco-friendly practices. In 2025, the market is expected to witness a significant shift towards sustainable packaging materials, driven by consumer awareness and regulatory initiatives. Companies are exploring biodegradable and recyclable materials to reduce their environmental footprint, which may lead to innovations in packaging design. The demand for sustainable solutions is not only a response to consumer preferences but also a strategic move to comply with emerging regulations aimed at reducing plastic waste. As a result, the industrial packaging market is likely to experience growth as manufacturers invest in sustainable practices and materials. This shift towards sustainability could also enhance brand reputation, attracting environmentally conscious consumers and fostering long-term loyalty.

Technological Integration

The integration of advanced technologies into the industrial packaging market is transforming how products are packaged and delivered. Automation and smart packaging solutions are becoming increasingly prevalent, enhancing efficiency and reducing costs. In 2025, the market is likely to witness a surge in the adoption of technologies such as IoT and RFID, which facilitate real-time tracking and inventory management. These innovations not only streamline operations but also improve supply chain transparency, which is crucial for businesses aiming to optimize their logistics. Moreover, the use of data analytics in packaging design allows companies to tailor solutions to specific customer needs, thereby enhancing user experience. As a result, the industrial packaging market is poised for growth driven by technological advancements that improve operational efficiency and customer satisfaction.

Consumer Demand for Customization

The growing consumer demand for customized products is significantly influencing the industrial packaging market. As brands strive to differentiate themselves in a competitive landscape, personalized packaging solutions are becoming essential. In 2025, it is anticipated that the market will see an increase in demand for packaging that reflects brand identity and caters to individual consumer preferences. This trend may lead to the development of innovative packaging designs that incorporate unique shapes, colors, and materials. Additionally, the rise of subscription services and limited-edition products further fuels the need for customized packaging solutions. Companies that can effectively respond to this demand are likely to gain a competitive edge, thereby driving growth in the industrial packaging market. The ability to offer tailored packaging solutions may also enhance customer loyalty and brand recognition.

Leave a Comment