Innovation in Packaging Materials

Innovation in packaging materials is transforming the Industrial Chemical Packaging Market. The development of advanced materials, such as biodegradable plastics and multi-layered films, is enhancing the performance and sustainability of chemical packaging. These innovations not only improve the shelf life of chemicals but also address environmental concerns associated with traditional packaging. As companies increasingly prioritize sustainability, the demand for innovative packaging solutions is expected to rise. This trend indicates a shift towards more eco-friendly options within the Industrial Chemical Packaging Market, potentially reshaping market dynamics in the coming years.

Rising Demand for Specialty Chemicals

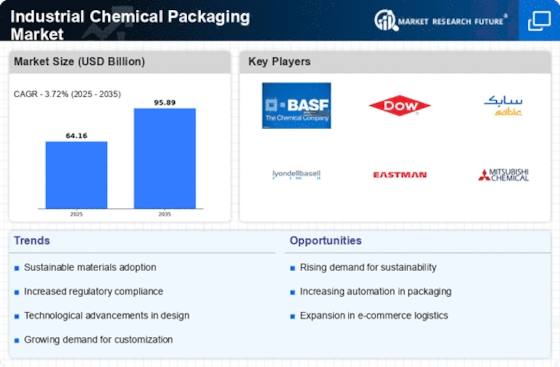

The Industrial Chemical Packaging Market is experiencing a notable increase in demand for specialty chemicals, driven by their diverse applications across various sectors. Industries such as pharmaceuticals, agriculture, and food processing are increasingly utilizing specialty chemicals, which require tailored packaging solutions to ensure product integrity and safety. The market for specialty chemicals is projected to grow at a compound annual growth rate (CAGR) of approximately 4.5% over the next few years. This growth necessitates innovative packaging solutions that can accommodate the unique properties of these chemicals, thereby propelling the Industrial Chemical Packaging Market forward.

Regulatory Compliance and Safety Standards

Regulatory compliance plays a crucial role in shaping the Industrial Chemical Packaging Market. Stringent regulations regarding the transportation and storage of hazardous materials necessitate the use of specialized packaging that meets safety standards. Governments and regulatory bodies are continuously updating guidelines to enhance safety measures, which in turn drives demand for compliant packaging solutions. The market is witnessing a shift towards packaging materials that not only comply with regulations but also offer enhanced safety features. This trend is expected to contribute to the growth of the Industrial Chemical Packaging Market as companies seek to mitigate risks associated with chemical handling.

Growth of the Chemical Manufacturing Sector

The expansion of the chemical manufacturing sector is a significant driver for the Industrial Chemical Packaging Market. As production capacities increase, the need for efficient and reliable packaging solutions becomes paramount. The chemical manufacturing sector is projected to grow at a CAGR of around 3.8%, leading to a higher volume of chemicals that require packaging. This growth is likely to stimulate demand for various packaging formats, including drums, containers, and bulk bags, tailored to the specific needs of chemical products. Consequently, the Industrial Chemical Packaging Market is poised to benefit from this upward trend in chemical production.

Increasing Focus on Supply Chain Efficiency

The Industrial Chemical Packaging Market is witnessing a growing emphasis on supply chain efficiency. Companies are increasingly seeking packaging solutions that streamline logistics and reduce costs. Efficient packaging can minimize waste, enhance product protection, and facilitate easier handling during transportation. As businesses strive to optimize their supply chains, the demand for packaging that supports these objectives is likely to increase. This focus on efficiency may lead to the adoption of smart packaging technologies, which can provide real-time tracking and monitoring of chemical products. Such advancements could significantly impact the Industrial Chemical Packaging Market, driving innovation and growth.