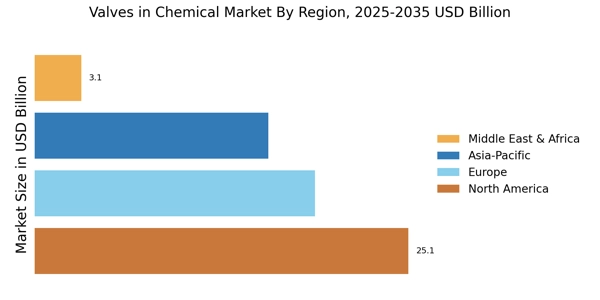

Expansion of Emerging Markets

The expansion of emerging markets is a significant driver for the Valves in Chemical Market. As economies in regions such as Asia-Pacific and Latin America continue to develop, the demand for chemical products is expected to rise. This growth is likely to create new opportunities for valve manufacturers, as industries in these regions invest in modernizing their infrastructure. In 2025, the chemical sector in emerging markets is projected to grow at a rate that outpaces developed regions, leading to an increased need for reliable and efficient valve solutions. Manufacturers are likely to focus on establishing a presence in these markets, adapting their products to meet local requirements and preferences. This trend could potentially reshape the competitive landscape of the Valves in Chemical Market.

Focus on Safety and Compliance

Safety and compliance are paramount in the Valves in Chemical Market, particularly as regulatory frameworks become more stringent. Industries are increasingly required to adhere to safety standards that govern the use of valves in chemical processes. This trend is likely to drive the demand for high-quality valves that meet or exceed regulatory requirements. In 2025, it is anticipated that the market for safety-compliant valves will witness substantial growth, as companies prioritize risk management and operational safety. The emphasis on safety not only protects workers and the environment but also enhances the reputation of companies within the chemical sector. Consequently, manufacturers are compelled to innovate and produce valves that align with these safety standards, thereby influencing the dynamics of the Valves in Chemical Market.

Rising Demand for Chemical Production

The increasing demand for chemicals across various industries, including pharmaceuticals, agriculture, and energy, drives the Valves in Chemical Market. As production processes expand, the need for efficient and reliable valves becomes paramount. In 2025, the chemical production sector is projected to grow at a compound annual growth rate of approximately 4.5%, necessitating advanced valve solutions to manage the flow of diverse chemicals. This growth is likely to be fueled by innovations in chemical processes and the introduction of new products, which require specialized valve technologies. Consequently, manufacturers are focusing on developing valves that can withstand extreme conditions and provide enhanced performance, thereby supporting the overall growth of the Valves in Chemical Market.

Sustainability and Environmental Concerns

Sustainability initiatives are increasingly influencing the Valves in Chemical Market. As environmental concerns gain prominence, chemical manufacturers are seeking to adopt more sustainable practices. This shift is likely to drive the demand for valves that minimize leakage and reduce waste during chemical processing. In 2025, the market for environmentally friendly valves is expected to expand, as companies strive to meet sustainability goals and regulatory requirements. The development of valves made from recyclable materials and those designed for energy efficiency is becoming a focal point for manufacturers. This trend not only addresses environmental challenges but also aligns with the growing consumer preference for sustainable products, thereby shaping the future landscape of the Valves in Chemical Market.

Technological Advancements in Valve Design

Technological advancements play a crucial role in shaping the Valves in Chemical Market. Innovations such as smart valves equipped with IoT capabilities are becoming increasingly prevalent. These smart valves enable real-time monitoring and control, enhancing operational efficiency and safety. The integration of automation technologies is expected to increase the demand for advanced valve solutions, as industries seek to optimize their processes. Furthermore, the introduction of materials that offer better resistance to corrosive chemicals is likely to expand the application range of valves. As a result, manufacturers are investing in research and development to create cutting-edge valve designs that meet the evolving needs of the chemical sector, thereby propelling the Valves in Chemical Market forward.

Leave a Comment