Growing Applications in the Automotive Sector

The Vapor Deposition Equipment Market is increasingly finding applications in the automotive sector, particularly in the production of advanced coatings and components. As automotive manufacturers strive for improved performance and aesthetics, vapor deposition techniques are being utilized to apply durable and lightweight coatings that enhance vehicle longevity and efficiency. The trend towards electric vehicles (EVs) is also driving demand for specialized coatings that improve battery performance and thermal management. Market projections suggest that the automotive segment will contribute significantly to the overall growth of the vapor deposition equipment market, with an anticipated CAGR of around 8% in the coming years. This growth reflects the evolving needs of the automotive industry and the critical role of vapor deposition technologies in meeting those needs.

Sustainability Focus in Manufacturing Processes

The Vapor Deposition Equipment Market is witnessing a growing emphasis on sustainability, driven by regulatory pressures and consumer demand for eco-friendly products. Manufacturers are increasingly adopting vapor deposition techniques that minimize environmental impact, such as using less hazardous materials and reducing energy consumption. This shift is reflected in the rising adoption of green technologies, which are projected to account for a significant share of the market by 2026. Companies that invest in sustainable vapor deposition equipment not only comply with regulations but also enhance their brand reputation, potentially leading to increased market share. The integration of sustainability into manufacturing processes is likely to reshape the competitive landscape of the Vapor Deposition Equipment Market.

Increased Investment in Research and Development

The Vapor Deposition Equipment Market is benefiting from increased investment in research and development (R&D) across various sectors. Companies are allocating substantial resources to innovate and improve vapor deposition technologies, aiming to enhance performance and reduce costs. This trend is particularly evident in the semiconductor and photovoltaic industries, where R&D efforts are focused on developing new materials and processes that can lead to higher efficiency and lower production costs. The influx of funding into R&D is likely to accelerate advancements in vapor deposition equipment, fostering a competitive environment that could lead to breakthroughs in technology. As a result, the market is expected to see a proliferation of innovative solutions that cater to diverse applications.

Rising Demand in Electronics and Optoelectronics

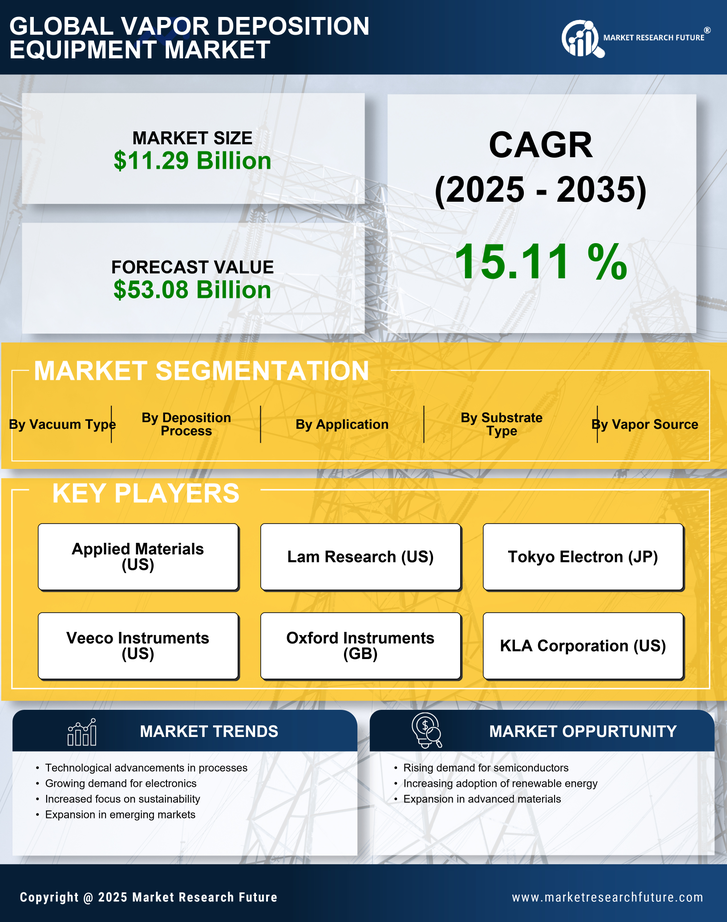

The Vapor Deposition Equipment Market is significantly influenced by the rising demand for electronic components and optoelectronic devices. As industries such as consumer electronics, telecommunications, and automotive continue to expand, the need for high-performance materials is becoming more pronounced. Vapor deposition techniques are essential for producing thin films used in displays, solar cells, and sensors, which are integral to modern electronic devices. Market analysis indicates that the demand for vapor deposition equipment in the electronics sector is expected to grow at a CAGR of approximately 10% over the next five years. This growth is indicative of the critical role that vapor deposition technologies play in meeting the evolving needs of the electronics market.

Technological Advancements in Vapor Deposition Equipment

The Vapor Deposition Equipment Market is experiencing a surge in technological advancements that enhance the efficiency and precision of deposition processes. Innovations such as atomic layer deposition (ALD) and molecular beam epitaxy (MBE) are becoming increasingly prevalent, allowing for the creation of ultra-thin films with exceptional uniformity. These advancements are not only improving product quality but also reducing waste, which is crucial in a competitive market. According to recent data, the market for ALD equipment alone is projected to grow at a compound annual growth rate (CAGR) of over 15% through the next few years. This trend indicates a robust demand for advanced vapor deposition technologies, which are essential for applications in semiconductors, optics, and coatings.