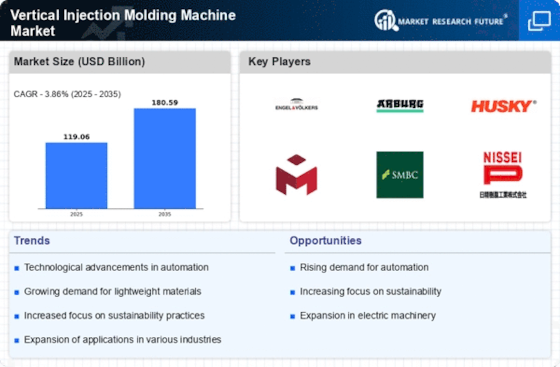

Expansion of End-User Industries

The expansion of end-user industries is a crucial driver for the Vertical Injection Molding Machine Market. Sectors such as automotive, healthcare, and consumer goods are experiencing robust growth, leading to increased demand for injection molded components. The automotive industry, in particular, is undergoing a transformation with the rise of electric vehicles, which require specialized parts that can be efficiently produced using vertical injection molding techniques. Recent statistics indicate that the automotive sector alone could contribute to a 10% increase in demand for vertical injection molding machines over the next few years. This expansion across various industries not only fuels the market but also encourages innovation within the Vertical Injection Molding Machine Market.

Increased Focus on Customization

Customization is becoming a pivotal driver in the Vertical Injection Molding Machine Market. As consumer preferences shift towards personalized products, manufacturers are compelled to adapt their production processes. Vertical injection molding machines offer the flexibility to produce small batches of customized parts efficiently. This capability is particularly advantageous in industries such as medical devices and consumer electronics, where tailored solutions are in high demand. Recent market analysis suggests that the customization trend could account for a significant portion of the market growth, with projections indicating a potential increase in demand for vertical injection molding machines by 15% over the next five years. This adaptability positions the Vertical Injection Molding Machine Market favorably for future expansion.

Rising Demand for Lightweight Materials

The Vertical Injection Molding Machine Market is witnessing a growing demand for lightweight materials, particularly in sectors such as automotive and aerospace. Manufacturers are increasingly adopting vertical injection molding techniques to produce lightweight components that meet stringent performance standards. This shift is driven by the need for fuel efficiency and reduced emissions, prompting companies to explore innovative materials like thermoplastics and composites. Market data indicates that the use of lightweight materials can lead to weight reductions of up to 20% in automotive applications. Consequently, this trend is expected to bolster the Vertical Injection Molding Machine Market as manufacturers seek to enhance their product offerings and meet evolving consumer preferences.

Sustainability and Eco-Friendly Practices

Sustainability is increasingly influencing the Vertical Injection Molding Machine Market as manufacturers strive to adopt eco-friendly practices. The push for sustainable production methods is prompting companies to invest in machines that minimize waste and energy consumption. Vertical injection molding machines are inherently more efficient, often requiring less material and energy compared to their horizontal counterparts. Market data reveals that companies implementing sustainable practices can reduce their operational costs by up to 25%. This trend not only aligns with regulatory pressures but also resonates with environmentally conscious consumers, thereby enhancing the market appeal of vertical injection molding machines. As sustainability becomes a core business strategy, the Vertical Injection Molding Machine Market is likely to see continued growth.

Technological Advancements in Vertical Injection Molding Machines

The Vertical Injection Molding Machine Market is experiencing a surge in technological advancements that enhance production efficiency and precision. Innovations such as multi-component injection molding and advanced control systems are becoming increasingly prevalent. These technologies allow manufacturers to produce complex parts with intricate designs, thereby expanding the application range of vertical injection molding machines. According to recent data, the integration of automation and robotics in the production process has led to a reduction in cycle times by up to 30%. This not only improves productivity but also reduces labor costs, making it a compelling choice for manufacturers. As these technologies continue to evolve, they are likely to drive further growth in the Vertical Injection Molding Machine Market.