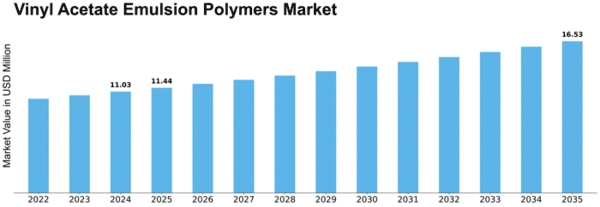

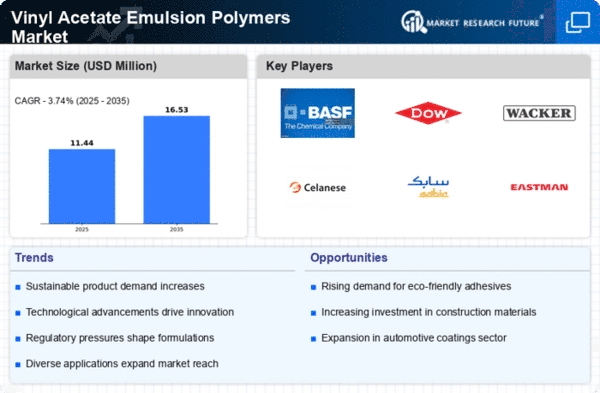

Vinyl Acetate Emulsion Polymers Size

Vinyl Acetate Emulsion Polymers Market Growth Projections and Opportunities

The market for vinyl acetate emulsion polymers is shaped by various factors that collectively impact its trajectory. One of the key drivers is the robust demand from industries such as adhesives, paints and coatings, and textiles. Vinyl acetate emulsion polymers serve as versatile binders in these applications, providing adhesive strength, durability, and versatility. The construction industry, in particular, plays a pivotal role in driving the demand for vinyl acetate emulsion polymers, as they are extensively used in architectural coatings, adhesives for tiles, and other construction-related applications.

Environmental regulations are significant determinants in the vinyl acetate emulsion polymers market. With an increasing focus on sustainability and eco-friendly products, there is a growing demand for water-based and low volatile organic compound (VOC) formulations. Vinyl acetate emulsion polymers, being water-based, align well with these environmental objectives, leading to a surge in their adoption across various industries. Stringent regulations and consumer preferences for eco-friendly options continue to drive the market towards more sustainable solutions.

Innovation and technological advancements are pivotal factors in the growth of the vinyl acetate emulsion polymers market. Continuous research and development efforts aim at improving the performance characteristics of these polymers, such as enhanced adhesion, flexibility, and durability. Manufacturers invest in developing new formulations that cater to the evolving needs of end-users, contributing to the overall expansion and competitiveness of the market.

The global economic landscape significantly influences the vinyl acetate emulsion polymers market. Economic growth and stability often correlate with increased construction activities, infrastructure development, and consumer spending on home improvement projects. Consequently, the demand for paints, coatings, and adhesives—key applications of vinyl acetate emulsion polymers—experiences an uptick during periods of economic prosperity. Conversely, economic downturns may lead to a temporary slowdown in construction and related industries, affecting the market for these polymers.

Raw material availability and pricing are crucial considerations for market participants in the vinyl acetate emulsion polymers sector. The primary raw material, vinyl acetate monomer, is derived from petrochemical sources. Fluctuations in oil prices directly impact the production cost of vinyl acetate emulsion polymers. Manufacturers closely monitor raw material markets to adjust their strategies and maintain cost-effectiveness in a competitive market.

Geographical factors also play a role in shaping the vinyl acetate emulsion polymers market. The concentration of manufacturing facilities, end-use industries, and regulatory frameworks varies across regions. For instance, regions with a strong emphasis on infrastructure development may witness higher demand for these polymers. Additionally, different regions may have varying regulatory standards, impacting the formulation requirements and market dynamics.

Leave a Comment