Customization Demand in Yarn Winding Machine Market

The Yarn Winding Machine Market is witnessing a surge in demand for customized solutions tailored to specific customer needs. As textile manufacturers seek to differentiate their products, the ability to customize yarn winding machines becomes increasingly valuable. This trend is driven by the diverse requirements of various textile applications, ranging from fashion to industrial textiles. Market data indicates that customized machines can enhance production efficiency by up to 15%, as they are designed to accommodate unique yarn types and winding patterns. Consequently, manufacturers that offer flexible and adaptable winding solutions are likely to capture a larger share of the Yarn Winding Machine Market. This growing emphasis on customization reflects a broader shift towards personalized manufacturing in the textile sector.

Sustainability Focus in Yarn Winding Machine Market

The Yarn Winding Machine Market is increasingly aligning with sustainability initiatives as environmental concerns gain prominence. Manufacturers are now prioritizing eco-friendly practices, which include the development of energy-efficient winding machines that reduce power consumption. Recent studies suggest that energy-efficient machines can lower operational costs by up to 30%, making them an attractive option for textile producers. Additionally, the use of sustainable materials in machine construction is becoming more prevalent, reflecting a commitment to reducing the carbon footprint of the textile industry. This focus on sustainability not only meets regulatory requirements but also appeals to environmentally conscious consumers, thereby enhancing brand reputation. As a result, companies that adopt sustainable practices are likely to thrive in the Yarn Winding Machine Market.

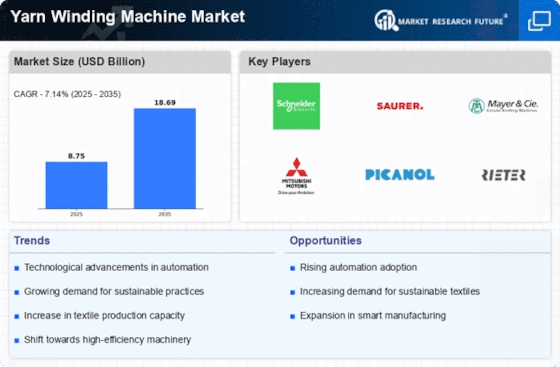

Technological Advancements in Yarn Winding Machine Market

The Yarn Winding Machine Market is experiencing a notable transformation due to rapid technological advancements. Innovations such as automation and digitalization are enhancing the efficiency and precision of yarn winding processes. For instance, the integration of IoT technology allows for real-time monitoring and data analytics, which can lead to improved operational efficiency. According to recent data, the adoption of advanced winding machines has increased productivity by approximately 20% in various textile manufacturing sectors. Furthermore, the development of high-speed winding machines is enabling manufacturers to meet the growing demand for high-quality yarns. This trend suggests that companies investing in cutting-edge technology are likely to gain a competitive edge in the Yarn Winding Machine Market.

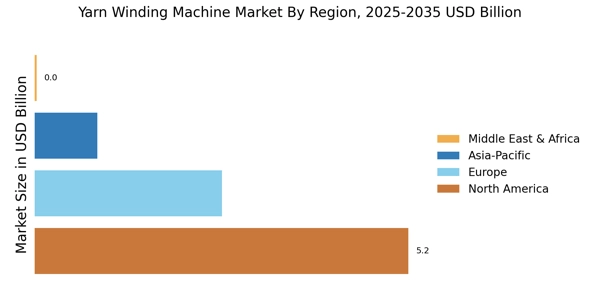

Expansion of Textile Industry in Yarn Winding Machine Market

The Yarn Winding Machine Market is benefiting from the ongoing expansion of the textile industry across various regions. As consumer demand for textiles continues to rise, manufacturers are ramping up production capabilities, which in turn drives the need for efficient yarn winding solutions. Recent data indicates that the textile industry is expected to grow at a rate of approximately 4% annually, leading to increased investments in machinery and technology. This expansion is prompting companies to upgrade their existing winding machines to enhance productivity and meet the evolving market demands. Therefore, the growth of the textile industry is likely to have a positive impact on the Yarn Winding Machine Market, creating a favorable environment for manufacturers.

Rising Demand for Technical Textiles in Yarn Winding Machine Market

The Yarn Winding Machine Market is experiencing a significant boost due to the rising demand for technical textiles. These specialized fabrics, which are used in various applications such as automotive, healthcare, and construction, require precise winding techniques to ensure optimal performance. Market analysis indicates that the technical textile segment is projected to grow at a compound annual growth rate of over 5% in the coming years. This growth is driving manufacturers to invest in advanced yarn winding machines capable of handling complex yarn structures and specifications. Consequently, the increasing focus on technical textiles is likely to create new opportunities for innovation and expansion within the Yarn Winding Machine Market.