Markt für Kunststoffextrusionsanlagen

Marktforschungsbericht über Kunststoff-Extrusionsanlagen: Nach Anlagentyp (Ein-Schnecken-Extruder, Doppel-Schnecken-Extruder, Platten-Extrusionslinien, Blasfolien-Extrusionslinien, Profil-Extrusionslinien), Nach Materialtyp (Polyethylen, Polypropylen, Polyvinylchlorid, Polystyrol, Polyethylenterephthalat), Nach Endverbrauchsindustrie (Verpackung, Bau, Automobil, Konsumgüter, Medizin), Nach technologischen Fortschritten (Konventionelle Extrusion, Hochgeschwindigkeits-Extrusion, Intelligente Extrusion, 3D-Druck-Extrusion) und Nach Region (Nordamerika, Europa, Südamerika, Asien-Pazifik, Naher Osten und Afrika) - Prognose bis 2035.

Marktübersicht für Kunststoffextrusionsgeräte

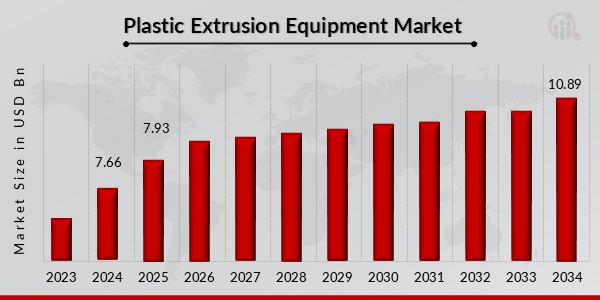

Laut MRFR-Analyse wurde die Marktgröße für Kunststoffextrusionsgeräte im Jahr 2022 auf 6,89 (Milliarden US-Dollar) geschätzt Es wird erwartet, dass der Markt für Kunststoffextrusionsgeräte von 7,14 Milliarden US-Dollar im Jahr 2023 auf 9,8 Milliarden US-Dollar im Jahr 2023 wachsen wird 2032. Die CAGR (Wachstumsrate) des Marktes für Kunststoffextrusionsgeräte wird im Prognosezeitraum (2024 – 2032) voraussichtlich bei etwa 3,58 % liegen.

Wichtige Markttrends für Kunststoffextrusionsgeräte hervorgehoben

Der Markt für Kunststoffextrusionsgeräte verzeichnet aufgrund verschiedener Faktoren ein erhebliches Wachstum. Die steigende Nachfrage nach Kunststoffprodukten in verschiedenen Branchen wie der Verpackungs-, Automobil- und Baubranche hat einen Bedarf an fortschrittlichen Extrusionstechnologien geschaffen, die die Produktionseffizienz steigern. Die Betonung von Recycling und Nachhaltigkeit treibt die Nachfrage nach Geräten weiter voran, die recycelte Kunststoffmaterialien herstellen können und im Einklang mit umweltfreundlichen Initiativen stehen. Darüber hinaus sorgen technologische Fortschritte bei Extrusionsprozessen, wie die Integration von Automatisierung und Industrie 4.0-Konzepten, für effizientere Abläufe und minimieren den Abfall, was weiter zur Marktexpansion beiträgt. Die Chancen in diesem Markt sind reichlich, insbesondere da Hersteller nach Innovationen und der Einführung neuer Produkte streben Materialien und Designs. Die steigende Nachfrage nach kundenspezifischen und speziellen Kunststoffprodukten bietet Ausrüstungslieferanten die Möglichkeit, maßgeschneiderte Lösungen anzubieten. Darüber hinaus bietet das Wachstum der Schwellenländer eine lukrative Expansionslandschaft, da die Industrie in diesen Regionen zunehmend fortschrittliche Extrusionstechnologien einsetzt. Es besteht auch die Möglichkeit, sich auf die Wartung und Nachrüstung von Geräten zu konzentrieren, wodurch die Leistung erhöht und die Lebensdauer vorhandener Maschinen verlängert werden kann. Jüngste Trends deuten auf eine Verlagerung hin zu nachhaltigeren Praktiken im Kunststoffextrusionssektor hin. Unternehmen konzentrieren sich zunehmend auf die Entwicklung biologisch abbaubarer und recycelbarer Materialien und reagieren damit auf die Nachfrage der Verbraucher nach umweltfreundlichen Produkten. Darüber hinaus ist der Einsatz intelligenter Technologien in Extrusionsanlagen gestiegen, die eine Echtzeitüberwachung und Datenanalyse ermöglichen. Dieser Schritt in Richtung Digitalisierung verbessert die Effizienz und senkt die Betriebskosten. Insgesamt prägt das Zusammenspiel von Innovation, Nachhaltigkeit und Marktnachfrage die zukünftige Ausrichtung des Marktes für Kunststoffextrusionsanlagen.

Abb. 1: Marktübersicht für Kunststoffextrusionsgeräte

Quelle: Primärforschung, Sekundärforschung, MRFR-Datenbank und Analyst Review

Markttreiber für Kunststoffextrusionsgeräte

Steigende Nachfrage nach Kunststoffprodukten

Auf dem Markt für Kunststoffextrusionsgeräte verzeichnet die Branche einen deutlichen Anstieg der Nachfrage nach Kunststoffprodukten in verschiedenen Sektoren. Da die Industrie weiterhin auf leichte Materialien setzt, die Haltbarkeit und Korrosionsbeständigkeit bieten, steigt der Bedarf an Kunststoffkomponenten. Branchen wie die Automobil-, Verpackungs-, Bau- und Konsumgüterbranche fordern zunehmend maßgeschneiderte Kunststofflösungen, die auf bestimmte Anwendungen zugeschnitten sind. Die Vielseitigkeit von Kunststoffen in Kombination mit fortschrittlichen Extrusionstechnologien ermöglicht es Herstellern, komplexe Formen und Designs zu entwickeln, die präzisen Spezifikationen entsprechen. Dieser Drang nach hochwertigen, effizienten und kostengünstigen Kunststofflösungen treibt das Wachstum im Markt voran. Während die Wirtschaft wächst und sich die Präferenzen der Verbraucher in Richtung nachhaltiger Materialien verlagern, stärkt die Nachfrage nach nachhaltigen und recycelbaren Kunststoffprodukten weiterhin den gesamten Markt für Kunststoffextrusionsanlagen. Die Produktionskapazitäten werden erweitert, da Hersteller in hochmoderne Extrusionsanlagen investieren möchten Diesen steigenden Anforderungen effizient gerecht zu werden. Das Engagement für Innovation sowie ein stärkerer Fokus auf die Abfallreduzierung und die Verbesserung der Recyclingfähigkeit von Kunststoffprodukten sind von wesentlicher Bedeutung. Diese Faktoren tragen gemeinsam zu robusten Wachstumsaussichten für den Markt für Kunststoffextrusionsanlagen bei.

Technologische Fortschritte bei Extrusionsprozessen

Technologische Fortschritte bei Extrusionsprozessen steigern die Produktivität und Effizienz im Markt für Kunststoffextrusionsgeräte erheblich. Innovative Techniken wie Coextrusion, Blasfolienextrusion und fortschrittliche Steuerungssysteme haben traditionelle Prozesse revolutioniert und ermöglichen es Herstellern, höhere Produktionsraten mit verbesserter Präzision zu erreichen. Dies ermöglicht die Herstellung komplexer Designs und mehrschichtiger Produkte, die zuvor eine Herausforderung darstellten, und erfüllt die sich entwickelnden Anforderungen verschiedener Anwendungen. Die Einführung von Industrie 4.0-Konzepten in Herstellungsprozesse, wie Automatisierung und integrierte Managementsysteme, treibt die Nachfrage nach moderner Extrusion weiter voran Ausrüstung. Da Hersteller versuchen, ihre Produktionslinien zu optimieren, wird erwartet, dass die Abhängigkeit von technologisch fortschrittlichen Extrusionslösungen zunehmen und das Wachstum auf dem Markt gefestigt wird.

Wachsende Umweltbelange und nachhaltige Praktiken

Das zunehmende Bewusstsein für Umweltprobleme katalysiert einen Wandel hin zu nachhaltigeren Herstellungspraktiken auf dem Markt für Kunststoffextrusionsgeräte Industrie. Da Verbraucher und Regulierungsbehörden nachhaltige Materialien fördern, sind Hersteller dazu veranlasst, in Geräte zu investieren, die die Verwendung von biologisch abbaubaren Kunststoffen und recycelten Materialien ermöglichen. Der Markt reagiert auf diese Bedürfnisse mit der Entwicklung innovativer Extrusionsanlagen, die in der Lage sind, alternative Rohstoffe zu verarbeiten und so die Umweltbelastung zu reduzieren. Diese Betonung der Nachhaltigkeit zwingt Hersteller dazu, ihre Anstrengungen zur Einhaltung bestehender Umweltvorschriften und -praktiken in ihren Produktionsprozessen zu verstärken. Infolgedessen dürfte die Nachfrage nach leistungsstarken, äußerst nachhaltigen und umweltfreundlichen Kunststoffextrusionssystemen erheblich steigen.

Einblicke in das Marktsegment für Kunststoffextrusionsgeräte

Einblicke in den Markt für Kunststoffextrusionsgeräte und Gerätetypen

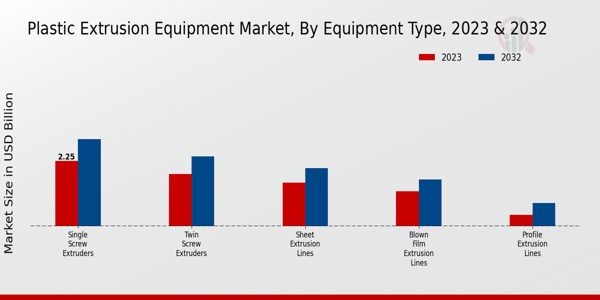

Das Segment „Equipment Type“ des Marktes für Kunststoffextrusionsgeräte zeigt eine dynamische Landschaft mit einer Gesamtmarktbewertung von bis zu 10.5pt; 7,14 Milliarden US-Dollar im Jahr 2023, und es wird prognostiziert, dass es im Zuge der Weiterentwicklung der Branche erheblich wachsen wird. Ein großer Teil dieses Umsatzes stammt von Einschneckenextrudern mit einem Wert von 2,25 Milliarden US-Dollar im Jahr 2023, was das Unternehmen zu einem dominierenden Akteur in diesem Segment macht, vor allem aufgrund seiner weit verbreiteten Anwendung und Effizienz bei der Verarbeitung verschiedener Kunststoffmaterialien. Danach wurde der Wert der Doppelschneckenextruder im selben Jahr auf 1,8 Milliarden US-Dollar geschätzt, was ihre Bedeutung für die Verbesserung der Misch- und Zuführfähigkeiten unterstreicht, die für die Herstellung fortschrittlicher Materialien von entscheidender Bedeutung sind.

Plattenextrusionslinien stellen einen weiteren wesentlichen Teil des Marktes dar, mit einem Wert von 1,5 Milliarden US-Dollar im Jahr 2023. Dies spiegelt die wachsende Nachfrage nach Kunststoffplatten für verschiedene Anwendungen wie Verpackung, Automobil und Bauwesen wider. Ebenso sind Blasfolien-Extrusionslinien im Wert von 1,2 Milliarden US-Dollar von Bedeutung, da sie in der Lage sind, flexible Verpackungsfolien herzustellen, ein Bereich, der in den letzten Jahren ein erhebliches Wachstum verzeichnete. Andererseits spielen Profilextrusionslinien, auch wenn sie im Jahr 2023 einen vergleichsweise geringeren Wert von 0,39 Milliarden US-Dollar haben, eine entscheidende Rolle bei der Herstellung kundenspezifischer Profile für Bau- und Industrieanwendungen, was darauf hindeutet, dass Nischenmärkte trotz eines geringeren Gesamtmarktanteils hochprofitabel sein können .

Das Wachstum des Marktes kann auf mehrere Faktoren zurückgeführt werden, darunter eine erhöhte Nachfrage nach leichten und langlebigen Kunststoffprodukten sowie technologischen Produkten Fortschritte in der Extrusionstechnik und die kontinuierliche Expansion der Automobil- und Verpackungsindustrie. Dennoch bleiben Herausforderungen wie schwankende Rohstoffpreise und Umweltvorschriften im Zusammenhang mit der Verwendung von Kunststoffen auf dem Markt für Kunststoffextrusionsgeräte weiterhin von großer Bedeutung.

Die Zukunft bietet Möglichkeiten für Innovationen, insbesondere bei der Entwicklung umweltfreundlicher Materialien und effizienter Recyclingprozesse in der Branche . Diese sich entwickelnde Landschaft unterstreicht die Notwendigkeit der Anpassungsfähigkeit der Gerätehersteller und treibt gleichzeitig das anhaltende Marktwachstum für verschiedene Gerätetypen voran. Mit diesen Einblicken in die Gerätetypsegmentierung des Marktes für Kunststoffextrusionsgeräte wird deutlich, dass kontinuierliche Investitionen und strategische Fokussierung erforderlich sein werden, um das volle Potenzial jedes Teilsegments auszuschöpfen.

Abb. 2: Markteinblicke für Kunststoffextrusionsgeräte

Quelle: Primärforschung, Sekundärforschung, MRFR-Datenbank und Analyst Review

Einblicke in den Markt für Kunststoffextrusionsgeräte und Materialtypen

Das Segment „Materialtyp“ umfasst Polyethylen, Polypropylen, Polyvinylchlorid, Polystyrol und Polyethylenterephthalat, die jeweils eine entscheidende Rolle spielen Rolle in der gesamten Marktdynamik. Aufgrund seiner Vielseitigkeit und seines breiten Anwendungsspektrums, insbesondere in Verpackungen und Konsumgütern, ist Polyethylen führend auf dem Markt. Polypropylen folgt dicht dahinter und wird wegen seines geringen Gewichts und seiner Robustheit geschätzt, was es ideal für Automobil- und Industrieanwendungen macht. Polyvinylchlorid ist wichtig für seine Anwendung im Baugewerbe, da es Haltbarkeit und Widerstandsfähigkeit gegenüber Umwelteinflüssen bietet. Polystyrol wird hauptsächlich für Isolierungs- und Verpackungslösungen verwendet. daufgrund seiner leichten Eigenschaften. Schließlich ist Polyethylenterephthalat in der Getränke- und Lebensmittelverpackungsindustrie von Bedeutung, da es hervorragende Barriereeigenschaften bietet. Die gegenseitige Abhängigkeit dieser Materialien unterstreicht die vielfältigen Einsatzmöglichkeiten von Kunststoff-Extrusionsgeräten und spiegelt sich ändernde Verbraucherpräferenzen und technologische Fortschritte wider, die aktuelle Statistiken und Trends auf dem Markt für Kunststoff-Extrusionsgeräte beeinflussen.

Einblicke in die Endverbrauchsbranche für den Markt für Kunststoffextrusionsgeräte

Die Segmentierung dieses Marktes nach Endverbrauchsindustrie unterstreicht seine Vielseitigkeit mit bemerkenswerten Anwendungen in den Bereichen Verpackung, Bauwesen, Automobil-, Konsumgüter- und Medizinbranche. Die Verpackung bleibt ein wichtiger Treiber, da die Nachfrage nach innovativen Verpackungslösungen aufgrund des gestiegenen Verbraucherbewusstseins und der Nachhaltigkeitstrends weiter steigt. Auch die Bauindustrie nutzt die Kunststoffextrusion für langlebige und leichte Materialien, was die Effizienz von Gebäuden steigert. Automobilanwendungen profitieren von energieeffizienten, leichten Komponenten und unterstützen so das Streben der Branche nach einer verbesserten Kraftstoffeffizienz. Konsumgüter finden vielfältige Anwendungsmöglichkeiten, da Kunststoffprodukte aufgrund ihrer Haltbarkeit und Anpassbarkeit immer beliebter werden. Schließlich sind im medizinischen Bereich präzisionsgefertigte Kunststofflösungen für medizinische Geräte und Verpackungen erforderlich, was die Bedeutung der Einhaltung gesetzlicher Vorschriften und Sicherheitsmerkmale dieser Produkte unterstreicht. Die Kombination dieser Faktoren deutet auf eine robuste Entwicklung des Marktes für Kunststoffextrusionsgeräte hin, die durch konsequente technologische Fortschritte und ein wachsendes Bewusstsein für ökologische Nachhaltigkeit angetrieben wird.

Einblicke in den technologischen Fortschritt des Marktes für Kunststoffextrusionsgeräte

Der Markt für Kunststoffextrusionsgeräte, insbesondere im Segment des technologischen Fortschritts, wird voraussichtlich ein deutliches Wachstum verzeichnen. In diesem Segment bleibt die konventionelle Extrusion aufgrund ihrer Zuverlässigkeit und gut etablierten Prozesse eine herausragende Methode, während die Hochgeschwindigkeitsextrusion aufgrund ihrer Effizienz in der Großserienproduktion an Bedeutung gewinnt und der wachsenden Nachfrage in verschiedenen Branchen gerecht wird. Intelligente Extrusion, Hebelwirkung Automatisierung und IoT werden für Hersteller, die ihre Produktionslinien optimieren, Ausfallzeiten verringern und die Produktqualität verbessern möchten, immer wichtiger. Darüber hinaus stellt die 3D-Druck-Extrusion eine transformative Wachstumschance dar, die durch ihre Fähigkeit angetrieben wird, maßgeschneiderte und komplexe Geometrien effizient herzustellen und verschiedene Branchen von der Automobilindustrie bis zum Gesundheitswesen zu bedienen.

Regionale Einblicke in den Markt für Kunststoffextrusionsgeräte

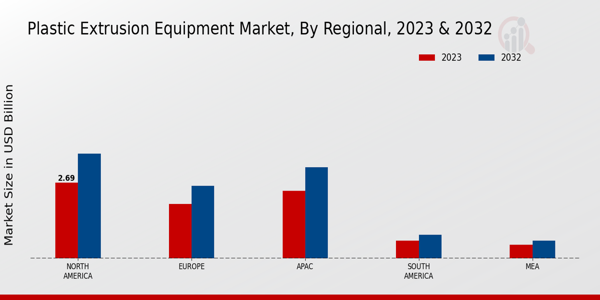

Nordamerika liegt mit einer Bewertung von 2,69 Milliarden US-Dollar an der Spitze, was eine starke Nachfrage widerspiegelt, die durch fortschrittliche Fertigungskapazitäten angetrieben wird innovative Anwendungen in verschiedenen Branchen. Europa folgt mit einem Marktwert von 1,93 Milliarden US-Dollar dicht dahinter und stellt seinen robusten Fertigungssektor und seinen Fokus auf Nachhaltigkeitsinitiativen zur Schau. Die APAC-Region stellt mit einem Wert von 2,4 Milliarden US-Dollar eine bemerkenswerte Kraft dar und profitiert von der schnellen Industrialisierung und dem steigenden Kunststoffverbrauch. Südamerika und MEA sind vergleichsweise kleinere Märkte mit einem Wert von 0,63 Milliarden US-Dollar bzw. 0,49 Milliarden US-Dollar im Jahr 2023, aber sie sind immer noch da bieten Wachstumschancen aufgrund zunehmender Infrastrukturprojekte und wachsender Produktionsstandorte. Die regionale Verteilung unterstreicht die Mehrheitsbeteiligung Nordamerikas am Markt, die durch technologische Fortschritte vorangetrieben wird, während das Marktwachstum im asiatisch-pazifischen Raum durch hohe Produktionskapazitäten und eine wachsende Mittelschicht vorangetrieben wird. Insgesamt spiegeln die Marktdaten für Kunststoffextrusionsgeräte vielfältige Chancen in den verschiedenen Regionen wider, die durch Wirtschaftswachstum, technologische Verbesserungen und die steigende Nachfrage nach Kunststoffprodukten beeinflusst werden.

Abb. 3: Regionale Einblicke in den Markt für Kunststoffextrusionsgeräte

Quelle: Primärforschung, Sekundärforschung, MRFR-Datenbank und Analyst Review

Hauptakteure und Wettbewerbseinblicke auf dem Markt für Kunststoffextrusionsgeräte

Die Wettbewerbseinblicke des Marktes für Kunststoffextrusionsgeräte zeigen eine dynamische Landschaft, die von Innovation, technologischen Fortschritten und anderen Faktoren geprägt ist sich entwickelnde Kundenpräferenzen. Dieser Markt, der für Branchen wie Verpackung, Automobil und Bauwesen von entscheidender Bedeutung ist, zeichnet sich durch eine Vielzahl von Akteuren aus, die an mehreren Fronten konkurrieren, darunter Produktqualität, Preise, Anpassungsfähigkeiten und Serviceangebote. Als Reaktion auf Umweltbedenken und regulatorische Auflagen konzentrieren sich Hersteller zunehmend auf nachhaltige Praktiken und energieeffiziente Maschinen. Die Wettbewerbsdynamik in diesem Sektor wird durch Faktoren wie geografische Präsenz, Marktdurchdringungsstrategien sowie Forschungs- und Entwicklungsinvestitionen beeinflusst, die alle darauf abzielen, die betriebliche Effizienz und die Kundenzufriedenheit zu steigern. Runtong hat sich durch sein Engagement eine starke Position auf dem Markt für Kunststoffextrusionsgeräte aufgebaut zur Lieferung hochwertiger Maschinen und innovativer Lösungen, die auf verschiedene Anwendungen zugeschnitten sind. Das Unternehmen ist für seine robusten Fertigungskapazitäten und ein umfassendes Produktportfolio bekannt, das unterschiedliche Branchenanforderungen abdeckt, von Folienextrusionssystemen bis hin zu Platten- und Profilextrusionslinien. Der strategische Ansatz von Runtong besteht darin, fortschrittliche Technologien und Automatisierungsfunktionen in seine Ausrüstung zu integrieren, die Produktionseffizienz zu steigern und die Betriebskosten für Endbenutzer zu senken. Darüber hinaus festigt Runtongs Engagement für Kundenservice und technischen Support seine Position auf dem Markt weiter und ermöglicht es dem Unternehmen, langfristige Beziehungen zu Kunden aufzubauen und gleichzeitig schnell auf Markttrends und -anforderungen zu reagieren. KraussMaffei, ein weiterer bedeutender Akteur auf dem Markt für Kunststoffextrusionsgeräte, rühmt sich ein reiches Erbe an technischer Exzellenz und Innovation im Bereich der Kunststoffverarbeitung. KraussMaffei ist für seine fortschrittlichen Extrusionslösungen bekannt und zeichnet sich durch seine hochgradig anpassbaren Maschinen aus, die die spezifischen Anforderungen verschiedener Branchen erfüllen können, darunter Automobil, Verpackung und Konsumgüter. Die Stärke des Unternehmens liegt in seiner Fähigkeit, Spitzentechnologie mit Branchenexpertise zu kombinieren und so nicht nur Hochleistungsgeräte, sondern auch ganzheitliche Lösungen zu liefern, die die gesamten Produktionsprozesse für seine Kunden verbessern. Mit einer starken Präsenz investiert KraussMaffei weiterhin in Forschung und Entwicklung, um seinen Wettbewerbsvorteil zu wahren, zeigt eine proaktive Haltung bei der Anpassung an Marktveränderungen und stärkt seinen Ruf als führendes Unternehmen im Bereich der Kunststoffextrusionsausrüstung.

Zu den wichtigsten Unternehmen auf dem Markt für Kunststoffextrusionsgeräte gehören

-

Runtong

-

KraussMaffei

-

Baiyun Machinery

-

Cincinnati Milacron

-

Husky-Spritzgusssysteme

-

SaintGobain

-

Nanjing Haisoon

-

Leistritz

-

Zhangjiagang City Xinrong Machinery

-

DavisStandard

-

Toshiba Machine

-

Milacron

-

SML Maschinengesellschaft

-

BattenfeldCincinnati

Entwicklungen in der Branche für Kunststoffextrusionsgeräte

Der Markt für Kunststoffextrusionsgeräte erlebt bedeutende Entwicklungen, wobei mehrere wichtige Akteure Fortschritte in Technologie und Expansion machen. Runtong und KraussMaffei haben ihre Produktangebote aktiv weiterentwickelt und so die Effizienz und den Energieverbrauch verbessert. Baiyun Machinery und Cincinnati Milacron konzentrieren sich auf die Entwicklung fortschrittlicher Maschinen, um der wachsenden Nachfrage nach leichten Kunststoffprodukten in verschiedenen Branchen gerecht zu werden. Husky Injection Molding Systems schmiedet zusammen mit SaintGobain Partnerschaften, um ihre Herstellungsprozesse zu verbessern und die Widerstandsfähigkeit der Lieferkette angesichts der anhaltenden Herausforderungen zu verbessern.

Bemerkenswert ist, dass Milacron und die SML Maschinengesellschaft einen erheblichen Anstieg der Marktbewertung verzeichneten, was auf eine steigende Nachfrage nach ihren Geräten hindeutet. Kürzlich gab BattenfeldCincinnati die Übernahme von Nanjing Haisoon bekannt, um seine Position auf dem asiatischen Markt zu stärken. Dieser Zusammenschluss unterstreicht einen Trend, bei dem große Unternehmen ihre Ressourcen konsolidieren, um ihren Wettbewerbsvorteil zu verbessern. Der Wachstumskurs des Kunststoffextrusionssektors wird weiterhin durch die zunehmende Verwendung recycelter Kunststoffe vorangetrieben, was Unternehmen wie DavisStandard und Toshiba Machine dazu veranlasst, in nachhaltige Produktionsmethoden zu investieren. Diese Entwicklungen zeigen eine robuste und sich entwickelnde Landschaft auf dem Markt für Kunststoffextrusionsgeräte, die von technologischen Fortschritten und strategischen Partnerschaften beeinflusst wird.

Einblicke in die Marktsegmentierung von Kunststoffextrusionsgeräten

Ausblick auf den Markt für Kunststoffextrusionsgeräte und Ausrüstungstypen

- Einzelschneckenextruder

- Doppelschneckenextruder

- Sheet Extrusion Lines

- Blasfolien-Extrusionslinien

- Profilextrusionslinien

Ausblick auf den Materialtyp des Marktes für Kunststoffextrusionsgeräte

- Polyethylen

- Polypropylen

- Polyvinylchlorid

- Polystyrol

- Polyethylenterephthalat

Marktausblick für den Markt für Kunststoffextrusionsgeräte und Endverbraucherindustrie

- Verpackung

- Konstruktion

- Automotive

- Konsumgüter

- Medizin

Ausblick auf den technologischen Fortschritt des Marktes für Kunststoffextrusionsgeräte

- Konventionelle Extrusion

- Hochgeschwindigkeitsextrusion

- Smart Extrusion

- 3D-Druck-Extrusion

Regionaler Ausblick auf den Markt für Kunststoffextrusionsgeräte

- Nordamerika

- Europa

- Südamerika

- Asien-Pazifik

- Naher Osten und Afrika

FAQs

What is the expected compound annual growth rate (CAGR) for the Plastic Extrusion Equipment Market from 2025 - 2034?

Plastic Extrusion Equipment Market is expected to grow with a CAGR of 3.58% in the period 2025-2035

Which region holds the largest market share in the Plastic Extrusion Equipment Market for 2024?

North America holds the largest market share in the Plastic Extrusion Equipment Market for 2024, valued at 2.69 USD Billion.

What is the projected market value of the Single Screw Extruders segment by 2034?

The projected market value of the Single Screw Extruders segment by 2034 is 3.0 USD Billion.

Who are the key players in the Plastic Extrusion Equipment Market?

Key players in the Plastic Extrusion Equipment Market include Runtong, KraussMaffei, and Cincinnati Milacron, among others.

What was the expected market value of the Twin Screw Extruders segment in 2024?

The expected market value of the Twin Screw Extruders segment in 2024 was 1.8 USD Billion.

How much is the market for Blown Film Extrusion Lines expected to be valued in 2034?

The market for Blown Film Extrusion Lines is expected to be valued at 1.6 USD Billion in 2034.

What is the estimated market value of the Europe region in 2034?

The estimated market value of the Europe region in 2034 is 2.57 USD Billion.

What growth factors are driving the Plastic Extrusion Equipment Market?

Growth factors driving the Plastic Extrusion Equipment Market include increasing demand for plastic products and technological advancements in extrusion processes.

What is the expected market value of the Profile Extrusion Lines segment by 2034?

The expected market value of the Profile Extrusion Lines segment by 2034is 0.8 USD Billion.

Bitte füllen Sie das folgende Formular aus, um ein kostenloses Muster dieses Berichts zu erhalten

Customer Stories

“This is really good guys. Excellent work on a tight deadline. I will continue to use you going forward and recommend you to others. Nice job”

“Thanks. It’s been a pleasure working with you, please use me as reference with any other Intel employees.”

“Thanks for sending the report it gives us a good global view of the Betaïne market.”

“Thank you, this will be very helpful for OQS.”

“We found the report very insightful! we found your research firm very helpful. I'm sending this email to secure our future business.”

“I am very pleased with how market segments have been defined in a relevant way for my purposes (such as "Portable Freezers & refrigerators" and "last-mile"). In general the report is well structured. Thanks very much for your efforts.”

“I have been reading the first document or the study, ,the Global HVAC and FP market report 2021 till 2026. Must say, good info! I have not gone in depth at all parts, but got a good indication of the data inside!”

“We got the report in time, we really thank you for your support in this process. I also thank to all of your team as they did a great job.”