Emerging Trends in Consumer Electronics

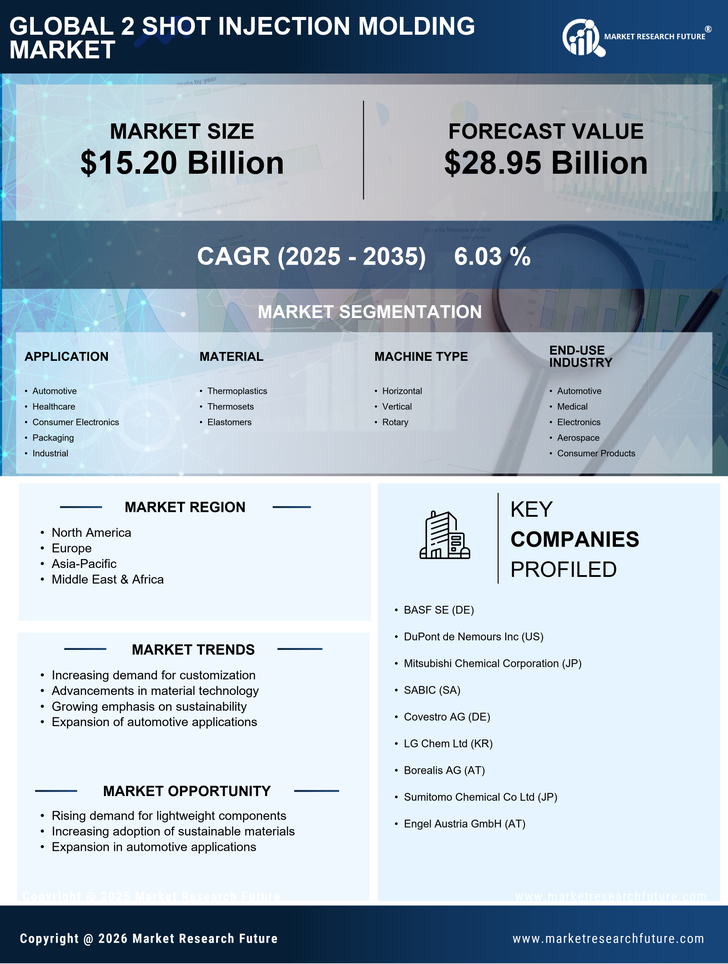

The 2 Shot Injection Molding Market is significantly influenced by emerging trends in consumer electronics, where the demand for aesthetically pleasing and functional products is on the rise. Manufacturers are leveraging two-shot molding to create complex designs that incorporate multiple colors and materials, enhancing the visual appeal of electronic devices. This trend is particularly evident in the production of smartphone casings, wearables, and other portable gadgets, where consumer preferences are shifting towards unique and customizable designs. Recent market data indicates that the consumer electronics sector is projected to grow at a rate of approximately 4% annually, further driving the need for innovative molding solutions. As a result, the 2 Shot Injection Molding Market is likely to benefit from these evolving consumer demands.

Growing Applications in Medical Devices

The 2 Shot Injection Molding Market is experiencing significant growth due to the expanding applications in the medical device sector. The ability to produce intricate components with multiple materials in a single process is particularly advantageous for medical applications, where precision and reliability are paramount. The increasing demand for advanced medical devices, such as drug delivery systems and diagnostic equipment, is propelling the adoption of two-shot molding techniques. Market analysis suggests that the medical device segment is expected to witness a robust growth rate, potentially exceeding 6% annually in the coming years. This trend underscores the importance of the 2 Shot Injection Molding Market in supporting innovations that enhance patient care and treatment outcomes.

Rising Demand for Lightweight Materials

The 2 Shot Injection Molding Market is experiencing a notable increase in demand for lightweight materials, particularly in sectors such as automotive and consumer electronics. Manufacturers are increasingly adopting two-shot molding techniques to produce complex parts that combine different materials, thereby reducing weight without compromising strength. This trend is driven by the need for fuel efficiency and enhanced performance in vehicles, as well as the growing consumer preference for lightweight electronic devices. According to recent data, the automotive sector is projected to account for a significant share of the 2 Shot Injection Molding Market, with a compound annual growth rate of approximately 5% over the next few years. This shift towards lightweight materials is likely to propel the industry forward, as companies seek innovative solutions to meet evolving market demands.

Sustainability and Eco-Friendly Practices

The 2 Shot Injection Molding Market is increasingly aligning with sustainability initiatives as manufacturers seek to reduce their environmental footprint. The adoption of eco-friendly materials and processes is becoming a priority, driven by consumer awareness and regulatory pressures. Two-shot molding allows for the efficient use of materials, minimizing waste and energy consumption during production. Furthermore, the ability to incorporate recycled materials into the molding process is gaining traction, appealing to environmentally conscious consumers. Market trends suggest that the sustainability focus could lead to a growth rate of around 5% in the 2 Shot Injection Molding Market, as companies strive to meet both regulatory requirements and consumer expectations for greener products.

Increased Focus on Automation and Efficiency

The 2 Shot Injection Molding Market is witnessing a surge in automation and efficiency improvements, which are essential for maintaining competitiveness. As manufacturers strive to optimize production processes, the integration of advanced robotics and automation technologies is becoming increasingly prevalent. This shift not only enhances production speed but also improves precision and reduces waste, thereby lowering overall operational costs. Recent statistics indicate that automated systems can increase production efficiency by up to 30%, making them a vital component of modern manufacturing strategies. Consequently, the emphasis on automation is likely to drive growth in the 2 Shot Injection Molding Market, as companies invest in state-of-the-art machinery to meet the rising demand for high-quality molded products.