Increasing Investment in R&D

The increasing investment in research and development (R&D) within the manufacturing sector is a notable driver for the 3 Axis 5 Axis Cnc Vertical Machining Center Market. Companies are allocating substantial resources to innovate and improve their production processes, which often involves upgrading to advanced CNC technologies. Recent data indicates that R&D spending in manufacturing has risen by approximately 5% annually, reflecting a commitment to enhancing product quality and operational efficiency. This trend suggests that as manufacturers strive to stay ahead of the competition, the demand for sophisticated 3 Axis and 5 Axis CNC machining centers will likely increase, as these machines are essential for developing new products and improving existing ones.

Emergence of Smart Manufacturing

The emergence of smart manufacturing technologies is reshaping the landscape of the 3 Axis 5 Axis Cnc Vertical Machining Center Market. The integration of IoT, AI, and data analytics into manufacturing processes enables real-time monitoring and optimization of production. This technological evolution is expected to enhance operational efficiency and reduce downtime, which is critical for manufacturers aiming to remain competitive. Market analysis suggests that the smart manufacturing sector could grow at a CAGR of 10% over the next decade. As manufacturers increasingly adopt these technologies, the demand for advanced CNC machining centers that can seamlessly integrate with smart systems is likely to surge, positioning 3 Axis and 5 Axis CNC machines at the forefront of this transformation.

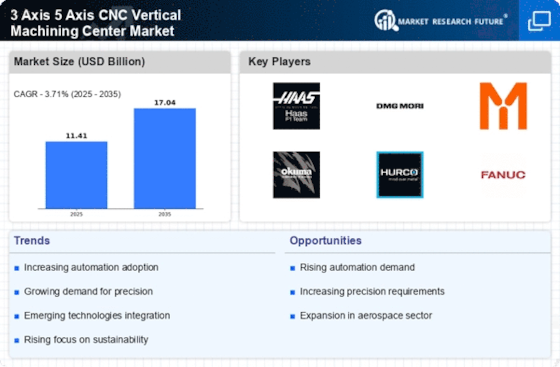

Growth of Automation in Manufacturing

The shift towards automation in manufacturing processes is significantly influencing the 3 Axis 5 Axis Cnc Vertical Machining Center Market. Automation enhances efficiency, reduces labor costs, and minimizes human error, making it an attractive option for manufacturers. According to recent statistics, the automation market is projected to reach USD 300 billion by 2026, with CNC machining centers playing a crucial role in this transformation. As companies increasingly invest in automated solutions, the demand for sophisticated CNC machines that can operate autonomously is likely to rise. This trend not only streamlines production but also allows for greater flexibility in manufacturing operations, further driving the adoption of 3 Axis and 5 Axis CNC technologies.

Rising Demand for Precision Engineering

The increasing demand for precision engineering across various sectors is a key driver for the 3 Axis 5 Axis Cnc Vertical Machining Center Market. Industries such as aerospace, automotive, and medical devices require high levels of accuracy and repeatability in their manufacturing processes. This trend is reflected in the market data, which indicates that the precision engineering sector is expected to grow at a compound annual growth rate of approximately 7% over the next five years. As manufacturers seek to enhance their production capabilities, the adoption of advanced CNC machining centers becomes essential. The ability to produce complex geometries with tight tolerances positions 3 Axis and 5 Axis CNC machines as vital tools in meeting these industry demands.

Expansion of the Aerospace and Defense Sector

The expansion of the aerospace and defense sector is significantly impacting the 3 Axis 5 Axis Cnc Vertical Machining Center Market. With increasing investments in aircraft manufacturing and defense technologies, there is a growing need for precision machining capabilities. The aerospace industry alone is projected to grow at a CAGR of 4% over the next five years, driving demand for advanced CNC machining solutions. As manufacturers in this sector require components with intricate designs and high tolerances, the adoption of 3 Axis and 5 Axis CNC machines becomes imperative. This trend not only supports the production of critical components but also enhances the overall efficiency and effectiveness of manufacturing operations within the aerospace and defense industries.

.png)