Expansion into Emerging Markets

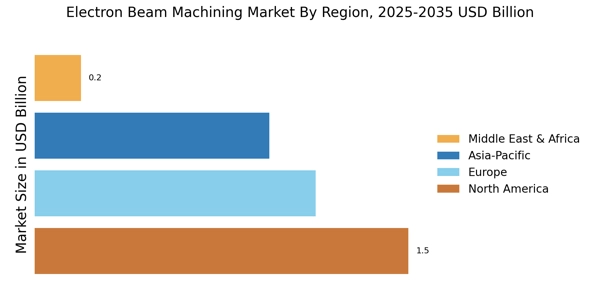

The Electron Beam Machining Market is poised for expansion into emerging markets, where industrialization is accelerating. Countries in Asia and South America are investing heavily in advanced manufacturing technologies, including electron beam machining. This expansion is driven by the need for high-quality components in rapidly growing sectors such as renewable energy and electronics. As these regions develop their manufacturing capabilities, the demand for precision machining solutions is expected to rise. Market analysts suggest that this trend could lead to a significant increase in market share for electron beam machining technologies, as local manufacturers seek to enhance their production capabilities and compete on a global scale.

Rising Demand for High-Precision Components

The demand for high-precision components is a key driver in the Electron Beam Machining Market. Industries such as aerospace, automotive, and electronics require components that meet stringent quality standards. Electron beam machining offers unparalleled precision, making it an attractive option for manufacturers. According to recent data, the aerospace sector alone is expected to account for a significant share of the market, driven by the need for lightweight and durable materials. The ability to machine complex shapes and thin-walled structures with minimal thermal distortion positions electron beam machining as a preferred choice. This trend is likely to continue, as industries increasingly prioritize precision in their manufacturing processes.

Sustainability and Eco-Friendly Manufacturing

Sustainability is becoming a focal point in the Electron Beam Machining Market, as manufacturers seek eco-friendly alternatives to traditional machining methods. Electron beam machining is inherently more efficient, producing less waste and requiring less energy compared to conventional techniques. This aligns with the growing emphasis on sustainable manufacturing practices across various sectors. Companies are increasingly adopting electron beam machining to reduce their carbon footprint and comply with environmental regulations. As a result, the market is witnessing a shift towards greener technologies, which is expected to drive growth in the coming years. The potential for reduced environmental impact positions the Electron Beam Machining Market favorably in an increasingly eco-conscious landscape.

Increased Investment in Research and Development

Investment in research and development is a critical driver for the Electron Beam Machining Market. Companies are allocating resources to innovate and improve electron beam technologies, which enhances their competitive edge. This focus on R&D is likely to yield advancements in beam quality, processing speed, and material compatibility. As industries evolve, the need for customized solutions becomes more pronounced, prompting manufacturers to invest in tailored electron beam machining processes. The anticipated growth in R&D spending is expected to foster innovation, leading to new applications and increased adoption of electron beam machining across various sectors. This trend underscores the importance of continuous improvement in maintaining relevance within the market.

Technological Advancements in Electron Beam Machining

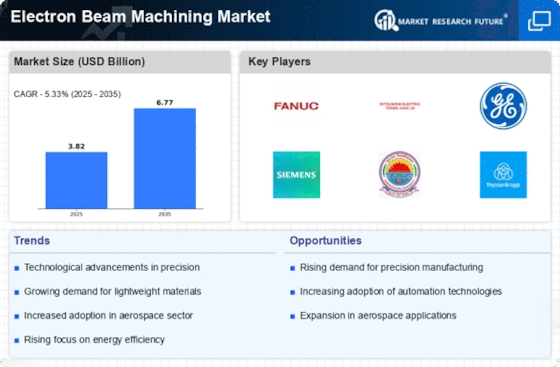

The Electron Beam Machining Market is experiencing a surge in technological advancements that enhance precision and efficiency. Innovations in electron beam technology, such as improved beam control and automation, are enabling manufacturers to achieve finer tolerances and faster processing times. For instance, the integration of computer numerical control (CNC) systems has streamlined operations, allowing for more complex geometries to be machined with ease. As a result, the market is projected to grow at a compound annual growth rate (CAGR) of approximately 6% over the next five years. This growth is indicative of the increasing demand for high-precision components in sectors such as aerospace and medical devices, where the Electron Beam Machining Market plays a crucial role.

.png)