Growing Adoption of Advanced Materials

The Electronic Discharge Machining Market is witnessing a growing adoption of advanced materials, such as titanium and high-performance alloys, which are increasingly utilized in various applications. These materials, known for their strength and durability, often pose challenges in traditional machining processes. However, EDM technology excels in machining these hard-to-cut materials, making it a preferred choice for manufacturers. The market for titanium, for example, is expected to expand significantly, with projections indicating a growth rate of around 6% annually. This trend suggests that as industries continue to innovate and utilize advanced materials, the Electronic Discharge Machining Market will likely benefit from increased demand for precision machining solutions.

Increased Focus on Precision Engineering

The Electronic Discharge Machining Market is benefiting from an increased focus on precision engineering across various sectors. Industries such as electronics, telecommunications, and defense are demanding higher precision in their components, which EDM technology can deliver. The trend towards miniaturization of electronic devices further amplifies this need, as smaller components require more intricate machining processes. Reports suggest that the precision engineering market is expected to grow at a rate of approximately 5% annually, indicating a strong demand for technologies that can meet these requirements. As a result, the Electronic Discharge Machining Market is likely to experience growth driven by the need for precision in manufacturing.

Expansion of Medical Device Manufacturing

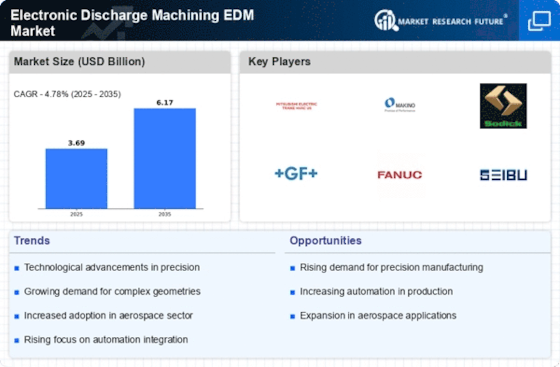

The Electronic Discharge Machining Market is significantly influenced by the expansion of medical device manufacturing. As the healthcare sector evolves, there is a growing need for intricate and precise components in medical devices, such as surgical instruments and implants. The Electronic Discharge Machining Market EDM is anticipated to reach over 600 billion USD by 2025, which indicates a robust growth trajectory. This expansion necessitates advanced manufacturing techniques, and EDM is well-suited for producing the high-precision parts required in this sector. Consequently, the Electronic Discharge Machining Market is likely to see increased investments and innovations aimed at catering to the specific needs of medical device manufacturers.

Emergence of Smart Manufacturing Practices

The Electronic Discharge Machining Market is poised for growth due to the emergence of smart manufacturing practices. The integration of Industry 4.0 technologies, such as IoT and AI, into manufacturing processes is transforming how EDM machines operate. These advancements enable real-time monitoring and optimization of machining processes, leading to improved efficiency and reduced operational costs. As manufacturers increasingly adopt smart technologies, the demand for advanced EDM solutions is expected to rise. The smart manufacturing market is projected to grow significantly, potentially reaching a valuation of over 300 billion USD by 2025. This trend suggests that the Electronic Discharge Machining Market will likely benefit from the ongoing digital transformation in manufacturing.

Rising Demand in Aerospace and Automotive Sectors

The Electronic Discharge Machining Market is experiencing a notable surge in demand, particularly from the aerospace and automotive sectors. These industries require precision components that can withstand extreme conditions, which EDM technology adeptly provides. The aerospace sector, for instance, is projected to grow at a compound annual growth rate of approximately 4.5% over the next few years, driving the need for advanced machining techniques. Similarly, the automotive industry is increasingly adopting EDM for manufacturing complex parts, such as molds and dies, which are essential for modern vehicle production. This rising demand is likely to propel the Electronic Discharge Machining Market forward, as manufacturers seek to enhance their production capabilities and meet stringent quality standards.