Research Methodology on the 3D Printing Filament Market

Introduction

The research methodology adopted for preparing the report “3D printing Filament Market” is described in this section. The marketing research approach adopted by MRFR helps in exploring and understanding the overall market outlook and highlights some of the important objectives of the report. A detailed approach towards the market is adopted, which starts with a comprehensive understanding of the market through desk research, secondary research and scoping surveys, together with inputs from industry professionals and existing participants. This helps in obtaining a better understanding of the target market and developing a better research hypothesis.

Research Type

The research approach adopted here is a combination of primary, secondary and expert interviews, mostly a descriptive and deductive research method is adopted. Deductive research is used to deduce industry trends, which are also verified using primary and secondary resources. The primary data is acquired from survey responses and interviews with various industry participants from across the world.

Secondary Research

Secondary research involves industry-wide surveys, the study of industry-related documents, and published resources both in hard copy as well as online and also business directories. Secondary resources consist of Journals and Magazines, White Papers, Government Websites, Reports, Annual Reports, News Websites and Some Other Resources.

Primary Research

Primary research is used to better understand the customer and market dynamics in different markets. Primary research consists of survey respondents from Tier 1 and Tier 2 companies. The primary research is conducted through telephonic interviews, email surveys, and in-person interviews. Questions include market dynamics, customer preferences, and needs of the market based on their segmentation and their level of customer satisfaction.

Data Analysis

Data analysis is used to understand the data gathered from both primary and secondary sources. Different analytical methods are used for data analysis which includes Statistical Analysis, Regression Modeling, Ratio Analysis, Time Series Analysis, and Others. This helps in providing insights into various aspects of the market.

Market Estimation and Forecasting

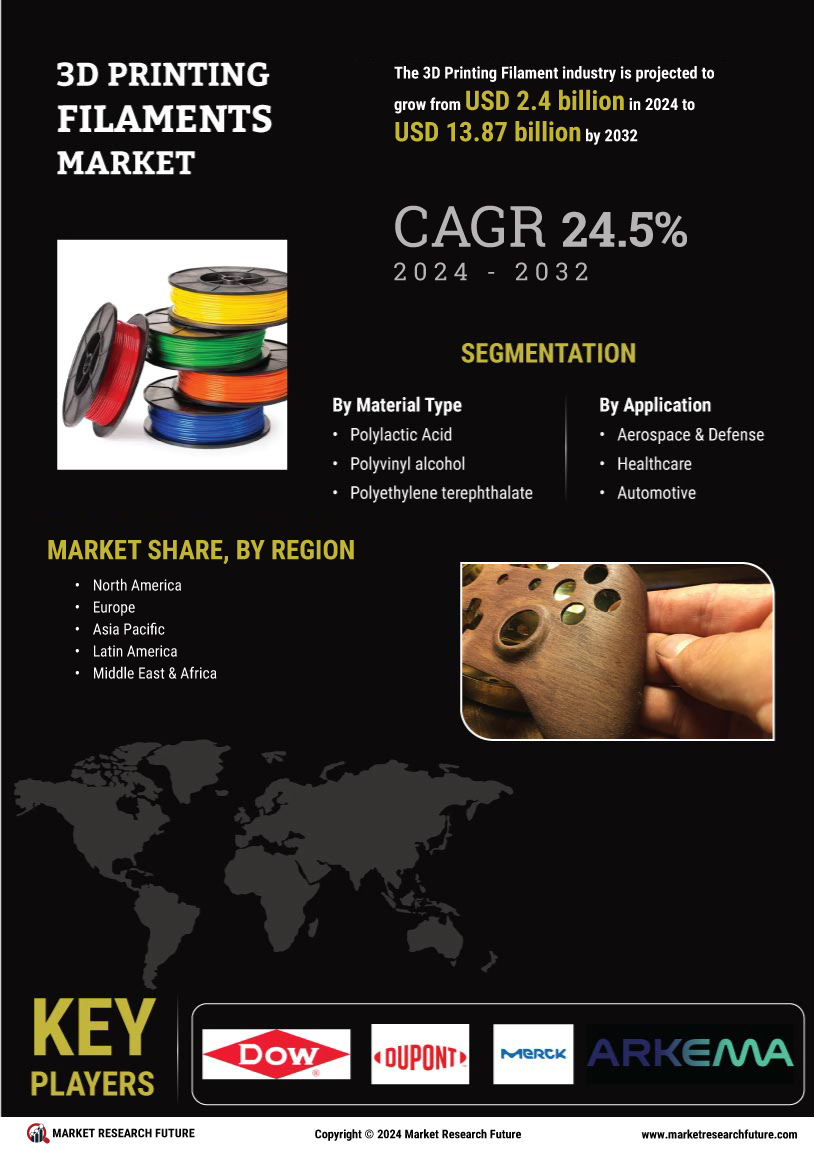

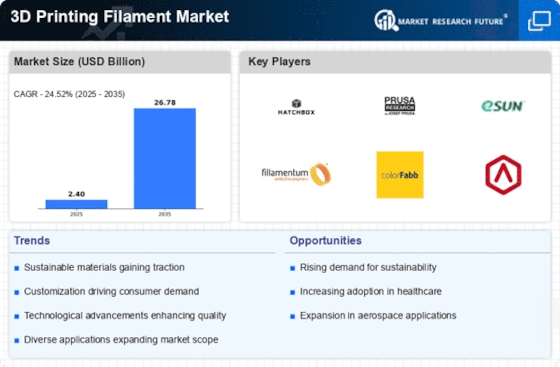

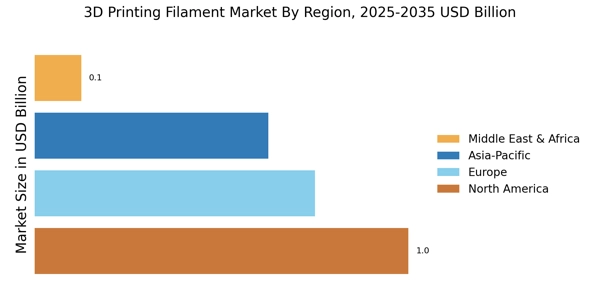

The global 3D printing filament market size, by region and by country is estimated using secondary research, primary research and market data from reliable sources. Forecasting is done by considering various factors such as revenue margins, technology trends, and technological advancements.

Report Objectives

The objective of this report is to provide a detailed analysis of the global 3D printing filament market and its associated trends and to estimate the market size, both in terms of value and volume by region/country. In addition, it provides a detailed understanding of factors influencing the market and their impact on the market dynamics.