Regulatory Compliance

Regulatory frameworks are increasingly influencing the Advanced Lead-Free Piezoelectric Materials Market. Governments worldwide are implementing stringent regulations regarding the use of hazardous materials, including lead. Compliance with these regulations is not optional; it is a critical factor for manufacturers aiming to maintain market access. As a result, companies are actively seeking lead-free alternatives to ensure adherence to safety standards. This regulatory pressure is likely to accelerate the transition towards advanced lead-free piezoelectric materials, as industries strive to align with environmental and health regulations. The market is expected to witness a surge in demand as manufacturers prioritize compliance, thereby driving growth in the Advanced Lead-Free Piezoelectric Materials Market.

Technological Innovations

Technological advancements are reshaping the landscape of the Advanced Lead-Free Piezoelectric Materials Market. Innovations in material science have led to the development of new compositions that enhance the performance of piezoelectric materials without the use of lead. For instance, materials such as sodium potassium niobate and bismuth sodium titanate are gaining traction due to their superior properties. The integration of these materials into various applications, including sensors and actuators, is expected to drive market growth. Furthermore, the ongoing research and development efforts are likely to yield even more efficient materials, potentially expanding the market's scope and applications. The Advanced Lead-Free Piezoelectric Materials Market is thus positioned to benefit from these technological breakthroughs.

Sustainability Initiatives

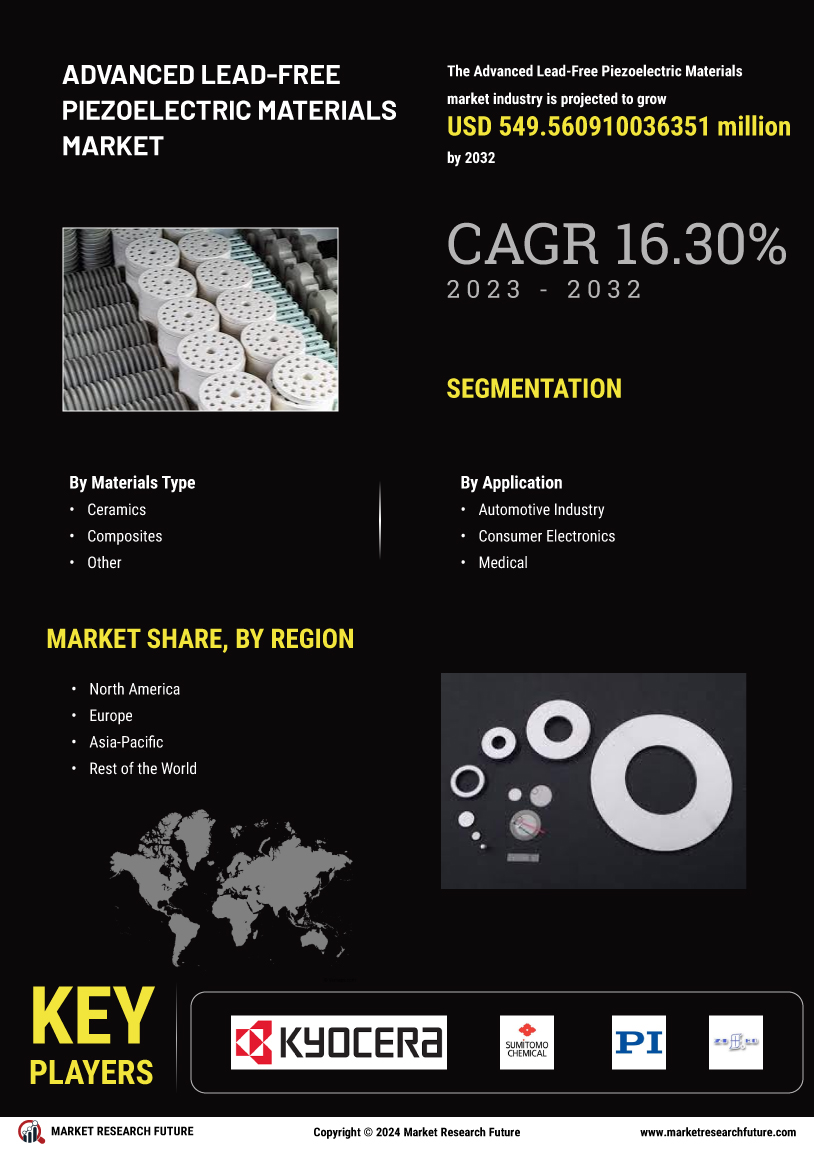

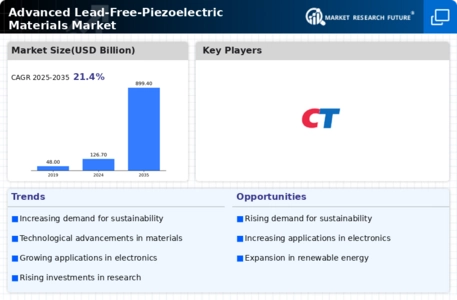

The increasing emphasis on sustainability is a pivotal driver for the Advanced Lead-Free Piezoelectric Materials Market. As environmental regulations tighten, industries are compelled to seek alternatives to lead-based materials, which are known for their toxicity. This shift is not merely a trend but a necessity, as consumers and manufacturers alike prioritize eco-friendly solutions. The market for lead-free piezoelectric materials is projected to grow significantly, with estimates suggesting a compound annual growth rate of over 10% in the coming years. This growth is indicative of a broader movement towards sustainable manufacturing practices, where the Advanced Lead-Free Piezoelectric Materials Market plays a crucial role in reducing environmental impact while maintaining performance standards.

Diverse Application Spectrum

The versatility of advanced lead-free piezoelectric materials is a significant driver for the Advanced Lead-Free Piezoelectric Materials Market. These materials find applications across various sectors, including consumer electronics, automotive, and healthcare. For example, in the automotive sector, lead-free piezoelectric materials are increasingly utilized in sensors and actuators, contributing to the development of smart vehicles. The healthcare industry also benefits from these materials in medical devices, where reliability and safety are paramount. As industries continue to explore innovative applications, the demand for lead-free alternatives is expected to rise, further propelling the market. The Advanced Lead-Free Piezoelectric Materials Market is thus poised for expansion as it caters to a broad range of applications.

Consumer Awareness and Demand

Consumer awareness regarding the environmental and health impacts of lead-based materials is a growing driver for the Advanced Lead-Free Piezoelectric Materials Market. As consumers become more informed, their preferences are shifting towards safer and more sustainable products. This change in consumer behavior is prompting manufacturers to innovate and adopt lead-free alternatives in their product lines. Market Research Future indicates that a significant portion of consumers is willing to pay a premium for products that are environmentally friendly. Consequently, this heightened demand for lead-free options is likely to stimulate growth in the Advanced Lead-Free Piezoelectric Materials Market, as companies respond to consumer preferences by integrating advanced lead-free materials into their offerings.