Demand for Enhanced Performance

The Advanced Materials for Flying Car Market is witnessing a surge in demand for materials that enhance performance characteristics. Lightweight composites, such as carbon fiber and advanced polymers, are increasingly favored for their strength-to-weight ratios. These materials enable flying cars to achieve higher speeds and improved fuel efficiency, which are critical for market acceptance. According to recent data, the use of advanced composites can reduce vehicle weight by up to 30%, significantly impacting performance metrics. As manufacturers strive to meet consumer expectations for speed and efficiency, the demand for these advanced materials is likely to grow, driving innovation and investment in the sector.

Regulatory Support for Innovation

The Advanced Materials for Flying Car Market is benefiting from a favorable regulatory environment that encourages innovation. Governments are increasingly recognizing the potential of flying cars to alleviate urban congestion and enhance transportation efficiency. As a result, there are initiatives aimed at streamlining the approval processes for new materials and technologies. This regulatory support is crucial for the development and commercialization of advanced materials, as it fosters collaboration between material scientists and aerospace engineers. The potential for reduced regulatory hurdles may accelerate the introduction of novel materials, thereby propelling the market forward and attracting investment from various stakeholders.

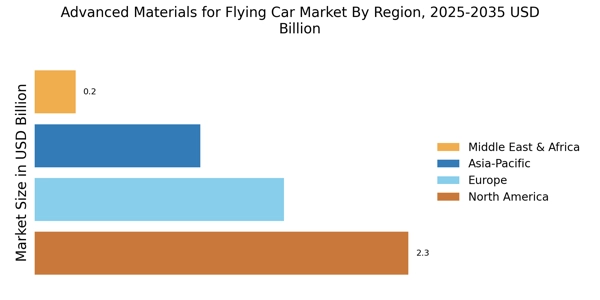

Growing Interest in Urban Air Mobility

The Advanced Materials for Flying Car Market is closely linked to the growing interest in urban air mobility solutions. As cities grapple with increasing traffic congestion, flying cars present a viable alternative for urban transportation. This trend is driving demand for advanced materials that can support the unique requirements of aerial vehicles. For example, materials that offer high durability and resistance to environmental factors are essential for ensuring safety and reliability in urban air travel. The projected market growth for urban air mobility is substantial, with estimates suggesting a market size of several billion dollars by the end of the decade, further stimulating the demand for advanced materials.

Sustainability Trends in Material Selection

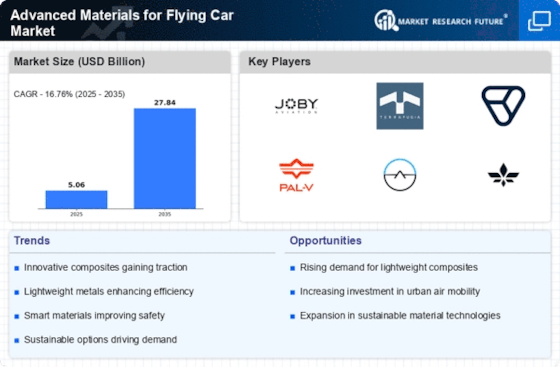

The Advanced Materials for Flying Car Market is increasingly influenced by sustainability trends in material selection. As environmental concerns gain prominence, manufacturers are seeking materials that minimize ecological impact. This includes the use of bio-based composites and recyclable materials that align with sustainability goals. The shift towards greener materials not only addresses regulatory pressures but also appeals to environmentally conscious consumers. Market data indicates that the demand for sustainable materials is expected to grow significantly, with projections suggesting a compound annual growth rate of over 10% in the coming years. This trend is likely to shape the future landscape of the advanced materials market for flying cars.

Technological Advancements in Material Science

The Advanced Materials for Flying Car Market is experiencing rapid technological advancements in material science. Innovations such as 3D printing and nanotechnology are enabling the development of materials with unprecedented properties. For instance, the ability to create complex geometries through additive manufacturing allows for the optimization of weight and strength in flying car components. Furthermore, advancements in nanomaterials are leading to the creation of lighter and more durable materials, which are essential for the performance of flying vehicles. As these technologies mature, they are expected to play a pivotal role in shaping the future of the flying car market, making advanced materials more accessible and cost-effective.