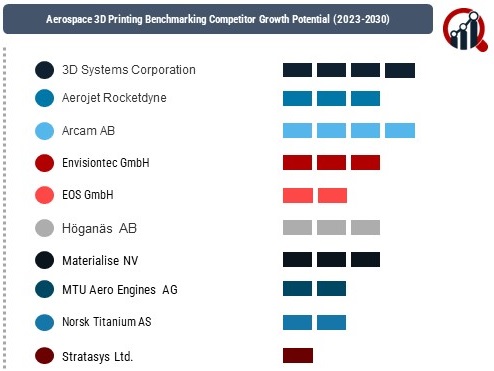

Top Industry Leaders in the Aerospace 3D Printing Market

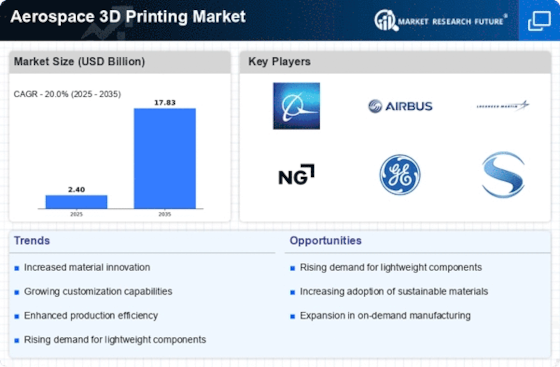

Aerospace 3D Printing Market Outlook

The competitive landscape of the Aerospace 3D Printing market is pivotal to the aerospace and aviation industry, revolutionizing manufacturing processes and enabling the production of complex components with enhanced efficiency. Key players in this market deploy various strategies to navigate challenges and meet the increasing demand for advanced aerospace 3D printing solutions.

Key Players:

3D Systems Corporation (US)

Aerojet Rocketdyne (US)

Arcam AB (Sweden)

Envisiontec GmbH (Germany)

EOS GmbH (Germany)

Höganäs AB (Sweden)

Materialise NV (Belgium)

MTU Aero Engines AG (Germany)

Norsk Titanium AS (Norway)

Stratasys Ltd. (Israel)

Strategies Adopted:

The Aerospace 3D Printing market deploy strategic initiatives to address the evolving needs of the aerospace industry. Notable strategies include continuous investment in research and development (R&D), diversification of 3D printing capabilities, strategic partnerships, and a focus on materials innovation. General Electric, for instance, emphasizes R&D investments to enhance its metal 3D printing technologies, showcasing a commitment to technological advancement. Strategic collaborations between Boeing and Stratasys aim to optimize 3D printing implementations for specific aerospace components, demonstrating a cooperative approach to addressing the diverse needs of the aerospace manufacturing sector.

Market Share Analysis:

The Aerospace 3D Printing market is influenced by factors such as the performance and reliability of 3D printing technologies, materials innovation, pricing competitiveness, and the ability to provide comprehensive solutions for various aerospace applications. Companies excelling in delivering high-quality, technologically advanced aerospace 3D printing solutions, ensuring compliance with stringent aerospace standards, and offering flexibility to meet the specific requirements of different aircraft and spacecraft models are strategically positioned to capture a larger market share. Establishing strong relationships with aerospace manufacturers, participating in industry collaborations, and understanding the regulatory landscape of aerospace 3D printing are crucial for maintaining a competitive edge in this sector.

News & Emerging Companies:

The Aerospace 3D Printing market has seen the emergence of new companies aiming to address the growing demand for innovative and cost-effective additive manufacturing solutions. Emerging entrants, such as EOS GmbH and Markforged, have gained attention for their focus on introducing advanced 3D printing technologies that cater to the specific needs of modern aerospace manufacturing. These emerging companies contribute to the market by introducing fresh perspectives and agile approaches to address the evolving requirements of aerospace manufacturing processes.

Industry Trends:

The Aerospace 3D Printing market underscores ongoing investment trends, with a strong emphasis on improving 3D printing system capabilities, expanding material options, and addressing the challenges of scaling production. Companies are investing significantly in the development of 3D printing technologies with increased precision, larger build volumes, and enhanced material compatibility. Advanced materials innovation, including high-performance polymers and advanced metal alloys, is a focus to meet the stringent requirements of aerospace applications. Investments in scaling production capabilities reflect the industry's response to the growing adoption of 3D printing in mainstream aerospace manufacturing, contributing to increased efficiency and reduced production costs.

Competitive Scenario:

The Aerospace 3D Printing market is marked by intense competition among established players and the entry of innovative newcomers. With aerospace manufacturers increasingly embracing additive manufacturing for its cost-effectiveness and design flexibility, companies aim to differentiate themselves by offering comprehensive 3D printing solutions that address the challenges of modern aerospace manufacturing. Established players focus on refining their 3D printing technologies, expanding their market presence through strategic collaborations with aerospace manufacturers, and staying informed about emerging materials and technologies. The entry of emerging companies adds dynamism to the market, fostering an environment of continuous improvement and responsiveness to the changing demands of the aerospace industry.

Recent Development

The Aerospace 3D Printing market witnessed a significant development as Airbus SE announced the successful production of a critical structural component for a next-generation aircraft using advanced 3D printing techniques. The achievement highlighted the capabilities of 3D printing in producing complex aerospace components with reduced weight and improved structural integrity. This development reinforces Airbus SE's commitment to advancing additive manufacturing technologies and solidifies its position as a key player in the market. The successful production is expected to contribute to the overall advancement of aircraft design and manufacturing, offering increased efficiency and sustainability in aerospace production. The announcement reflects the industry's continuous efforts to evolve and provide cutting-edge solutions that address the challenges posed by the dynamic aerospace manufacturing landscape, emphasizing the importance of advanced aerospace 3D printing technologies in shaping the future of aircraft production.