Lightweight Materials Demand

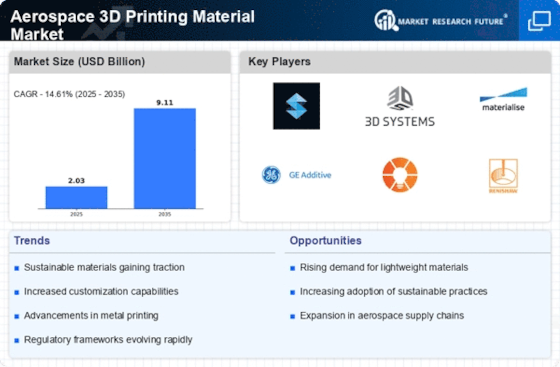

The demand for lightweight materials in the Aerospace 3D Printing Material Market is becoming increasingly pronounced. The aerospace sector is under constant pressure to improve fuel efficiency and reduce emissions, which can be achieved by utilizing lighter components. 3D printing enables the production of complex geometries that traditional methods cannot easily replicate, allowing for the creation of lightweight structures without compromising strength. For instance, titanium and advanced polymers are gaining traction as preferred materials due to their favorable strength-to-weight ratios. Market analysis suggests that the lightweight materials segment is projected to grow at a compound annual growth rate of over 15% in the coming years, indicating a robust trend towards the integration of 3D printing technologies in aerospace applications.

Cost Efficiency in Production

The Aerospace 3D Printing Material Market is experiencing a notable shift towards cost efficiency in production processes. Traditional manufacturing methods often involve high material waste and extensive labor costs. In contrast, 3D printing allows for additive manufacturing, which significantly reduces waste by using only the necessary amount of material. This efficiency not only lowers production costs but also shortens lead times, making it an attractive option for aerospace manufacturers. Reports indicate that companies adopting 3D printing technologies can reduce costs by up to 30%, thereby enhancing their competitive edge. As the industry continues to evolve, the emphasis on cost-effective solutions is likely to drive further adoption of 3D printing materials, reshaping the landscape of aerospace manufacturing.

Innovation in Material Science

Innovation in material science is a pivotal driver of the Aerospace 3D Printing Material Market. The continuous development of new materials tailored for 3D printing is expanding the possibilities for aerospace applications. Advanced composites, high-performance polymers, and metal alloys are being engineered to meet the specific demands of the aerospace sector, such as heat resistance and durability. This innovation is crucial as it allows manufacturers to explore new design paradigms and enhance the performance of aerospace components. Furthermore, research indicates that the introduction of novel materials could lead to a market expansion of over 20% in the next five years. As material science progresses, it is likely to play a central role in shaping the future of 3D printing in aerospace.

Rapid Prototyping Capabilities

Rapid prototyping capabilities are a significant driver in the Aerospace 3D Printing Material Market. The ability to quickly produce prototypes allows aerospace companies to test and iterate designs more efficiently, reducing the time from concept to production. This agility is crucial in a highly competitive market where innovation is key. 3D printing facilitates the creation of prototypes that can be tested under real-world conditions, enabling engineers to identify potential issues early in the design process. As a result, companies can bring new products to market faster, enhancing their responsiveness to customer needs. The increasing reliance on rapid prototyping is expected to propel the growth of the 3D printing materials market, as firms seek to leverage these capabilities for competitive advantage.

Regulatory Compliance and Certification

Regulatory compliance and certification processes are critical drivers in the Aerospace 3D Printing Material Market. The aerospace sector is heavily regulated, with stringent requirements for materials used in aircraft manufacturing. 3D printing materials must meet specific standards to ensure safety and reliability. As the industry evolves, manufacturers are increasingly focusing on developing materials that comply with these regulations, which can be a complex and time-consuming process. However, advancements in material science are enabling the creation of certified 3D printing materials that meet aerospace standards. This trend not only enhances the credibility of 3D printed components but also encourages wider adoption within the industry. The ongoing efforts to streamline certification processes are likely to further stimulate growth in the aerospace 3D printing materials market.