Regulatory Support

Regulatory support is emerging as a vital driver for the Allyl Polyether Market. Governments worldwide are increasingly implementing regulations that promote the use of safer and more sustainable materials. This regulatory landscape encourages industries to transition towards allyl polyethers, which are often viewed as safer alternatives to conventional chemicals. For instance, regulations aimed at reducing volatile organic compounds (VOCs) in products have led to a heightened interest in allyl polyethers, which typically exhibit lower VOC emissions. Additionally, incentives for using environmentally friendly materials further bolster the market. As regulatory frameworks continue to evolve, the Allyl Polyether Market is likely to see increased adoption and integration of these materials across various applications.

Sustainability Initiatives

The increasing emphasis on sustainability initiatives is a pivotal driver for the Allyl Polyether Market. As industries strive to reduce their environmental footprint, the demand for eco-friendly materials has surged. Allyl polyethers, known for their biodegradable properties, align well with these sustainability goals. This shift is particularly evident in sectors such as construction and packaging, where companies are actively seeking alternatives to traditional materials. According to recent data, the market for sustainable materials is projected to grow at a compound annual growth rate of over 10% in the coming years. This trend not only reflects consumer preferences but also regulatory pressures that encourage the adoption of greener solutions. Consequently, the Allyl Polyether Market stands to benefit significantly from this growing focus on sustainability.

Technological Advancements

Technological advancements play a crucial role in shaping the Allyl Polyether Market. Innovations in production processes and formulations have led to enhanced performance characteristics of allyl polyethers, making them more appealing to various applications. For instance, advancements in polymerization techniques have improved the efficiency and cost-effectiveness of allyl polyether production. This has resulted in a broader range of products that cater to specific industry needs, such as adhesives, coatings, and composites. Furthermore, the integration of smart technologies in manufacturing processes is expected to streamline operations and reduce waste, thereby increasing profitability. As industries continue to adopt these technological innovations, the Allyl Polyether Market is likely to experience robust growth, driven by the demand for high-performance materials.

Rising Demand in Emerging Markets

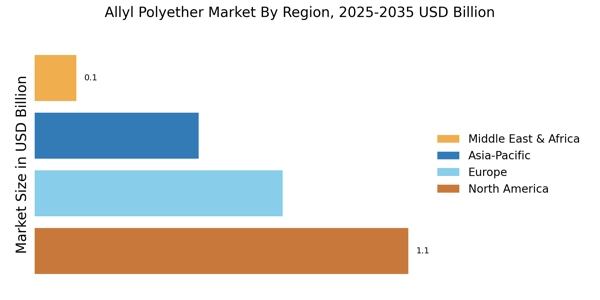

The rising demand in emerging markets is a significant driver for the Allyl Polyether Market. As economies in regions such as Asia-Pacific and Latin America continue to develop, there is an increasing need for advanced materials in various sectors, including automotive, construction, and consumer goods. The expanding middle class in these regions is also contributing to higher consumption rates of products that utilize allyl polyethers. Market data indicates that the Asia-Pacific region alone is expected to account for a substantial share of the allyl polyether market by 2026, driven by rapid industrialization and urbanization. This trend presents lucrative opportunities for manufacturers and suppliers within the Allyl Polyether Market, as they seek to establish a foothold in these burgeoning markets.

Growing Applications in Diverse Industries

The growing applications of allyl polyethers across diverse industries serve as a compelling driver for the Allyl Polyether Market. These materials are increasingly utilized in sectors such as automotive, electronics, and healthcare due to their unique properties, including chemical resistance and flexibility. For example, in the automotive industry, allyl polyethers are used in coatings and adhesives that enhance vehicle performance and durability. Similarly, in the electronics sector, they are employed in encapsulation and insulation applications. The versatility of allyl polyethers allows for their integration into a wide range of products, thereby expanding their market reach. As industries continue to explore innovative applications, the Allyl Polyether Market is poised for sustained growth, driven by the demand for multifunctional materials.