Growth of the Automotive Sector

The automotive sector is a primary driver of the Aluminum Die Casting Mold Release Agent Market. With the ongoing shift towards electric vehicles and lightweight designs, the demand for aluminum components is surging. This trend is prompting automotive manufacturers to seek advanced mold release agents that can enhance production efficiency and part quality. The automotive industry is projected to account for a significant share of the aluminum die casting market, which in turn will bolster the demand for effective mold release agents. As automakers continue to innovate and optimize their production processes, the need for high-performance mold release agents will likely remain strong.

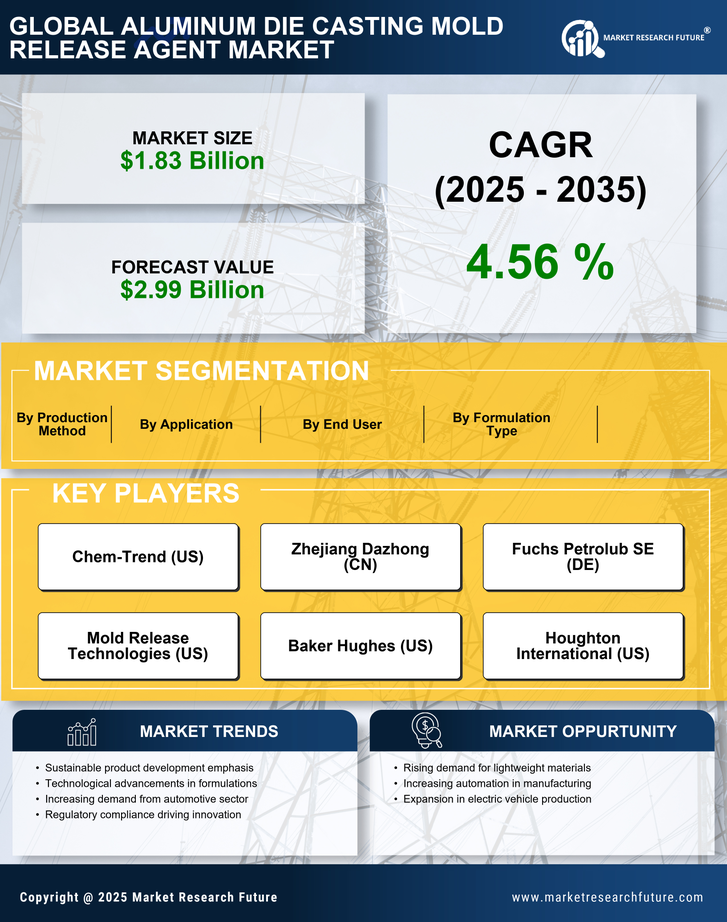

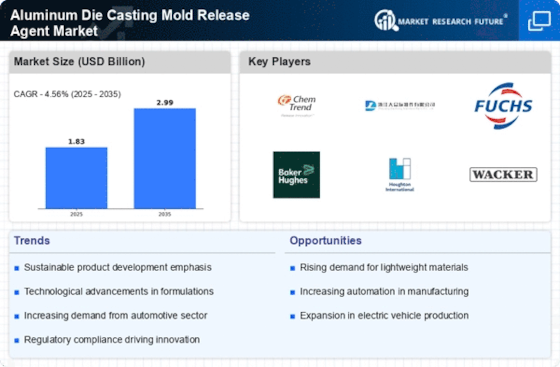

Rising Demand for Lightweight Materials

The Aluminum Die Casting Mold Release Agent Market is experiencing a notable increase in demand for lightweight materials across various sectors, particularly in automotive and aerospace. As manufacturers strive to enhance fuel efficiency and reduce emissions, aluminum components are favored due to their lightweight properties. This trend is expected to drive the demand for effective mold release agents that facilitate the production of intricate aluminum parts. The market for aluminum die casting is projected to grow at a compound annual growth rate of approximately 5.5% over the next few years, indicating a robust need for high-performance mold release agents that can support this growth.

Technological Innovations in Die Casting

Technological advancements in die casting processes are significantly influencing the Aluminum Die Casting Mold Release Agent Market. Innovations such as improved die designs, enhanced cooling techniques, and automation are leading to more efficient production cycles. These advancements necessitate the development of specialized mold release agents that can withstand higher temperatures and pressures, ensuring optimal performance. The integration of smart technologies, such as IoT and AI, into die casting operations is also likely to create new opportunities for mold release agents that can adapt to varying production conditions, thereby enhancing overall efficiency and product quality.

Expanding Applications in Various Industries

The Aluminum Die Casting Mold Release Agent Market is benefiting from the expanding applications of aluminum die casting in diverse sectors, including electronics, consumer goods, and construction. As industries seek to leverage the advantages of aluminum, such as corrosion resistance and aesthetic appeal, the demand for specialized mold release agents is likely to rise. For instance, the electronics sector requires precision components that necessitate high-quality mold release agents to ensure flawless finishes. This diversification of applications is expected to contribute to the overall growth of the market, as manufacturers seek tailored solutions to meet specific industry requirements.

Increasing Focus on Sustainable Manufacturing

Sustainability is becoming a pivotal concern within the Aluminum Die Casting Mold Release Agent Market. Manufacturers are increasingly adopting eco-friendly practices, which include the use of biodegradable and non-toxic mold release agents. This shift is driven by regulatory pressures and consumer preferences for sustainable products. The market is witnessing a gradual transition towards greener alternatives, with a projected increase in the share of sustainable mold release agents. This trend not only aligns with global sustainability goals but also enhances the competitive edge of manufacturers who prioritize environmentally responsible practices.