Expansion of 5G Technology

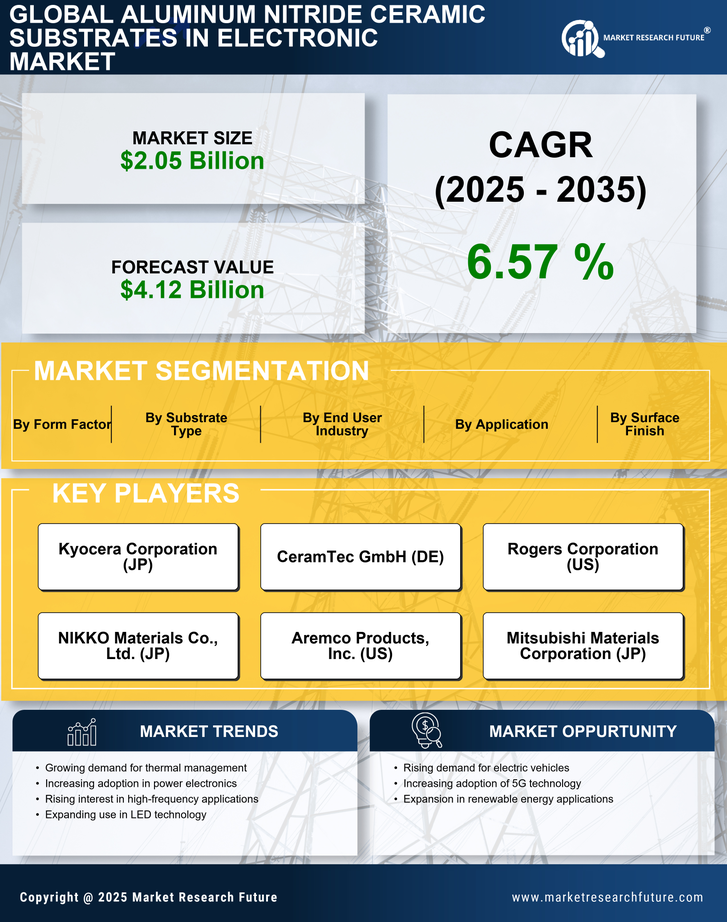

The rollout of 5G technology is driving the Aluminum Nitride Ceramic Substrates In Electronic Market forward. As telecommunications companies invest heavily in 5G infrastructure, the demand for high-frequency electronic components increases. Aluminum nitride substrates are particularly suited for high-frequency applications due to their superior thermal management capabilities. The 5G market is expected to grow exponentially, with projections indicating that the global 5G services market could exceed 700 billion USD by 2025. This expansion necessitates the use of advanced materials like aluminum nitride, which can handle the thermal and electrical demands of next-generation communication devices, thereby propelling the Aluminum Nitride Ceramic Substrates In Electronic Market.

Growth in Renewable Energy Sector

The Aluminum Nitride Ceramic Substrates In Electronic Market is also benefiting from the growth in the renewable energy sector. As the world shifts towards sustainable energy solutions, the demand for efficient power electronics in solar inverters and wind turbines is increasing. Aluminum nitride substrates offer excellent thermal conductivity, which is crucial for managing heat in power conversion systems. The renewable energy market is projected to grow significantly, with estimates suggesting that by 2025, investments in renewable energy could surpass 2 trillion USD. This trend is likely to enhance the demand for aluminum nitride substrates, as manufacturers seek materials that can withstand the rigorous demands of renewable energy applications.

Increasing Adoption of Electric Vehicles

The Aluminum Nitride Ceramic Substrates In Electronic Market is experiencing a notable surge due to the increasing adoption of electric vehicles (EVs). As automotive manufacturers strive to enhance the performance and efficiency of EVs, the demand for advanced electronic components rises. Aluminum nitride substrates, known for their excellent thermal conductivity and electrical insulation properties, are becoming essential in power electronics used in EVs. The market for electric vehicles is projected to grow significantly, with estimates suggesting that by 2025, The Aluminum Nitride Ceramic Substrates In Electronic Market could reach over 30 million units. This growth directly influences the Aluminum Nitride Ceramic Substrates In Electronic Market, as manufacturers seek reliable materials to support the high-performance requirements of EV power systems.

Rising Demand for Miniaturization in Electronics

The trend towards miniaturization in electronics is significantly influencing the Aluminum Nitride Ceramic Substrates In Electronic Market. As devices become smaller and more compact, the need for efficient thermal management solutions becomes critical. Aluminum nitride substrates, with their high thermal conductivity and low dielectric constant, are well-suited for compact electronic applications. The miniaturization trend is expected to continue, with the global market for miniaturized electronics projected to reach 1 trillion USD by 2025. This demand for smaller, more efficient devices is likely to drive the adoption of aluminum nitride substrates, as manufacturers seek materials that can meet the thermal and electrical requirements of miniaturized electronic components.

Technological Advancements in Semiconductor Manufacturing

Technological advancements in semiconductor manufacturing are playing a pivotal role in the Aluminum Nitride Ceramic Substrates In Electronic Market. Innovations in fabrication techniques are enabling the production of more efficient and reliable semiconductor devices. Aluminum nitride substrates are increasingly being utilized in high-power and high-frequency applications, which are essential for modern electronic devices. The semiconductor market is expected to grow at a compound annual growth rate (CAGR) of over 5% through 2025, driven by the demand for advanced electronics. This growth is likely to create a favorable environment for aluminum nitride substrates, as they are integral to the performance of next-generation semiconductor devices.